Resourceful treatment method and treatment system for LED-MOCVD ammonia-containing waste gas

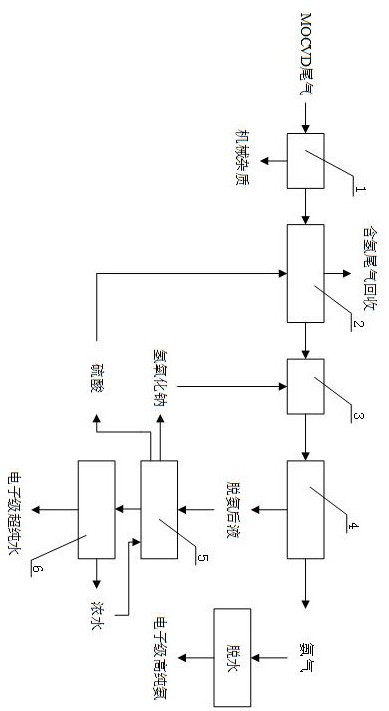

A treatment method and technology of a treatment system, which are applied in the field of LED-MOCVD ammonia-containing waste gas resource treatment method and treatment system thereof, can solve the problems of complex waste gas composition, large acid consumption, and low ammonia gas recovery rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The LED-MOCVD waste gas containing ammonia in a semiconductor research institute has an ammonia content of 0.5%.

[0037] Step 1: After the ammonia-containing waste gas is passed through a 200-mesh bag filter to remove mechanical impurities, it is sprayed and absorbed by acid. The concentration of sulfuric acid used is 1%, and the ammonia absorption rate is 99.95%.

[0038] (2) The spray absorption liquid is ammonium sulfate solution, add 1% sodium hydroxide solution to adjust the pH to 10, and the NH in the solution 4 + All converted to NH 3.

[0039] (3) Contains NH 3 The solution enters the hydrophobic membrane system for deamination, and the pressure difference on both sides of the membrane is controlled to be 10kpa. The purity of the ammonia gas on the ammonia gas side is 99.999%, and the moisture content is 0.001%.

[0040] (4) The ammonia gas recovered by the hydrophobic membrane system is further dried and dehydrated, and the dehydration method is drying. ...

Embodiment 2

[0044] A company's LED-MOCVD waste gas containing ammonia, the ammonia content is 3.2%.

[0045] Step 1: Ammonia-containing exhaust gas passes through a 200-mesh filter bag filter to remove mechanical impurities, and then undergoes acid spray absorption. The concentration of sulfuric acid used is 6%, and the ammonia absorption rate is 99.98%.

[0046] (2) The spray absorption liquid is ammonium sulfate solution, add 1% sodium hydroxide solution to adjust the pH to 12, and the NH in the solution 4 + All converted to NH 3 .

[0047] (3) Contains NH 3 The solution enters the hydrophobic membrane system for deamination, and the pressure difference on both sides of the membrane is controlled to be 50kpa. The purity of the ammonia gas on the ammonia gas side is 99.9994%, and the moisture content is 0.0006%.

[0048] (4) The ammonia gas recovered by the hydrophobic membrane system is further dried and dehydrated, and the dehydration method is pressure swing adsorption. The puri...

Embodiment 3

[0052] The LED-MOCVD waste gas containing ammonia in a semiconductor research institute has an ammonia content of 1.4%.

[0053] Step 1: After the ammonia-containing waste gas is passed through a 200-mesh bag filter to remove mechanical impurities, it is sprayed and absorbed by acid. The concentration of sulfuric acid used is 3%, and the ammonia absorption rate is 99.98%.

[0054] (2) The spray absorption liquid is ammonium sulfate solution, add 3% sodium hydroxide solution to adjust the pH to 11, and the NH in the solution 4 + All converted to NH 3 .

[0055] (3) Contains NH 3 The solution enters the hydrophobic membrane system for deamination, and the pressure difference on both sides of the membrane is controlled to be 20kpa. The purity of the ammonia gas on the ammonia gas side is 99.9996%, and the moisture content is 0.0004%.

[0056] (4) The ammonia gas recovered by the hydrophobic membrane system is further dried and dehydrated, and the dehydration method is drying...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com