Thermal barrier coating material with low infrared transmittance and preparation method thereof

A technology of infrared transmittance and thermal barrier coating, applied in the field of thermal barrier coating, can solve the problems of inability to resist infrared radiation, phase change, etc., and achieve the effect of convenient operation, simple process and strong reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

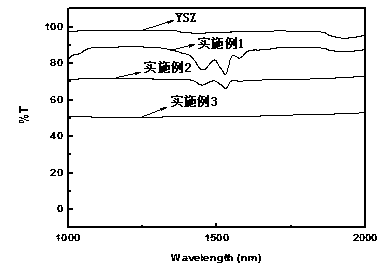

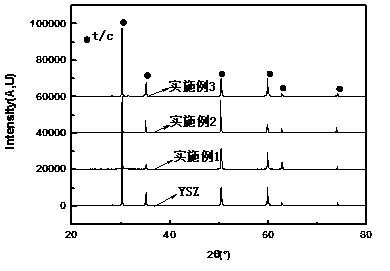

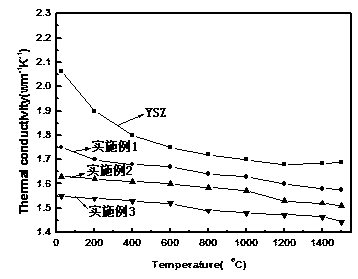

[0020] A thermal barrier coating material with low infrared transmittance and a preparation method thereof, specifically comprising the following steps:

[0021] (1) The powder raw material ZrO 2 , Y 2 o 3 , NiO, Er 2 o 3 , Yb 2 o 3 Place in a resistance furnace at a rate of 5°C / min to 1000°C and bake for 2 hours, then cool to room temperature with the furnace to remove the moisture and CO adsorbed in the oxide raw material 2 , to obtain dry powder raw material;

[0022] (2) Accurately and quickly weigh the mass of each oxide after pretreatment according to the designed stoichiometric ratio, wherein the molar ratio of each powder raw material is NiO:Er 2 o 3 : Yb 2 o 3 : Y 2 o 3 : ZrO 2 =0:1.0:1.0:4.0:94, mix and put into a ball mill jar, add a certain amount of zirconia balls, absolute ethanol and oxide according to the mass ratio of 4:3:1, to obtain a mixture;

[0023] (3) The mixture was mechanically ball milled for 6 hours, evaporated to dryness, and dried in...

Embodiment 2

[0029] A thermal barrier coating material with low infrared transmittance and a preparation method thereof, specifically comprising the following steps:

[0030] (1) The powder raw material ZrO 2 , Y 2 o 3 , NiO, Er 2 o 3 , Yb 2 o 3 Place in a resistance furnace at a rate of 5°C / min to 1000°C and bake for 2 hours, then cool to room temperature with the furnace to remove the moisture and CO adsorbed in the oxide raw material 2 , to obtain dry powder raw material;

[0031] (2) Accurately and quickly weigh the mass of each oxide after pretreatment according to the designed stoichiometric ratio, wherein the molar ratio of each powder raw material is NiO:Er 2 o 3 : Yb 2 o 3 : Y 2 o 3 : ZrO 2 =1.0:2.0:2.0:4.2:90.8, mix and put it into a ball mill jar, add a certain amount of zirconia balls, absolute ethanol and oxide according to the mass ratio of 4:3:1, to obtain a mixture;

[0032] (3) The mixture was mechanically ball milled for 10 hours, evaporated to dryness, and ...

Embodiment 3

[0038] A thermal barrier coating material with low infrared transmittance and a preparation method thereof, specifically comprising the following steps:

[0039] (1) The powder raw material ZrO 2 , Y 2 o 3 , NiO, Er 2 o 3 , Yb 2 o 3 Place in a resistance furnace at a rate of 5°C / min to 1000°C and bake for 2 hours, then cool to room temperature with the furnace to remove the moisture and CO adsorbed in the oxide raw material 2 , to obtain dry powder raw material;

[0040] (2) Accurately and quickly weigh the mass of each oxide after pretreatment according to the designed stoichiometric ratio, wherein the molar ratio of each powder raw material is NiO:Er 2 o3 : Yb 2 o 3 : Y 2 o 3 : ZrO 2 =2.0:2.5:2.5:4.5:88.5, mix and put into a ball mill jar, add a certain amount of zirconia balls, absolute ethanol and oxide according to the mass ratio of 4:3:1, to obtain a mixture;

[0041] (3) The mixture was mechanically ball milled for 8 hours, evaporated to dryness, and dried ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com