A kind of preparation method of o-fluorobenzaldehyde

A technology of fluorobenzaldehyde and benzaldehyde, which is applied in the field of preparation of o-fluorobenzaldehyde, can solve the problems of large consumption of catalyst, environmental pollution, reduction of the scope of use of o-fluorobenzaldehyde and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

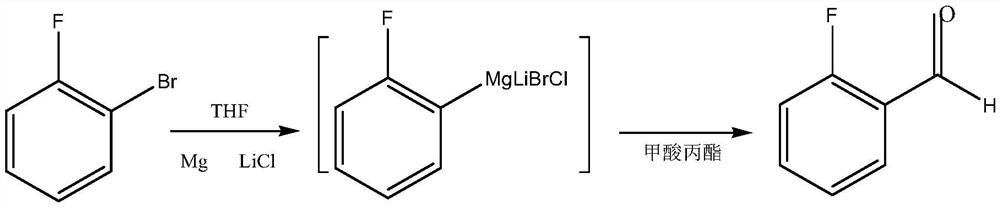

Method used

Image

Examples

Embodiment 1

[0034] A preparation method of o-fluorobenzaldehyde, comprising the following steps:

[0035] (1) 1.25 moles of propyl formate were dissolved in 150 ml of anhydrous tetrahydrofuran to obtain solution A.

[0036] (2) 1 mole of o-fluorobromobenzene was dissolved in 200 ml of anhydrous tetrahydrofuran to obtain solution B.

[0037] (3) Put 1 mole of anhydrous lithium chloride and 1.15 moles of magnesium into a reaction flask, add 50 ml of anhydrous tetrahydrofuran, heat to a slight boil (about 65 ° C), and drop 2 ml of dibromoethane to initiate the reaction.

[0038] (4) Under reflux, solution B was added dropwise into the above-mentioned reaction flask, and the temperature was controlled at 63-67°C during the process.

[0039] (5) After feeding, cool down to 20-30°C, add solution 1 dropwise; react for 1 hour after feeding.

[0040] (6) Cool down to below 10°C, quench with dilute hydrochloric acid, post-process, and refine by vacuum distillation.

[0041] (7) 113.5 g of o-fluo...

Embodiment 2

[0043] A preparation method of o-fluorobenzaldehyde, comprising the following steps:

[0044] (1) 1 mole of propyl formate was dissolved in 100 ml of anhydrous tetrahydrofuran to obtain solution A.

[0045] (2) 1 mole of o-fluorobromobenzene was dissolved in 150 ml of anhydrous tetrahydrofuran to obtain solution B.

[0046] (3) Put 1 mole of anhydrous lithium chloride and 1.15 moles of magnesium into a reaction flask, add 30 ml of anhydrous tetrahydrofuran, heat to a slight boil (about 65° C.), and drop 2 ml of dibromoethane to initiate the reaction.

[0047] (4) Under reflux, solution B was added dropwise into the above-mentioned reaction flask, and the temperature was controlled at 63-67°C during the process.

[0048] (5) After feeding, cool down to 20-30°C, add solution 1 dropwise; react for 0.5 hours after feeding.

[0049] (6) Cool down to below 10°C, quench with dilute hydrochloric acid, post-process, and refine by vacuum distillation.

[0050] (7) 110 g of o-fluorobe...

Embodiment 3

[0052] A preparation method of o-fluorobenzaldehyde, comprising the following steps:

[0053] (1) 1.5 moles of propyl formate were dissolved in 200 ml of anhydrous tetrahydrofuran to obtain solution A.

[0054] (2) 1 mole of o-fluorobromobenzene was dissolved in 250 ml of anhydrous tetrahydrofuran to obtain solution B.

[0055] (3) Put 1 mole of anhydrous lithium chloride and 1.15 moles of magnesium into a reaction flask, add 70 ml of anhydrous tetrahydrofuran, heat to a slight boil (about 65° C.), and drop 2 ml of dibromoethane to initiate the reaction.

[0056] (4) Under reflux, solution B was added dropwise into the above-mentioned reaction flask, and the temperature was controlled at 63-67°C during the process.

[0057] (5) After feeding, cool down to 20-30°C, add solution 1 dropwise; react for 1.5 hours after feeding.

[0058] (6) Cool down to below 10°C, quench with dilute hydrochloric acid, post-process, and refine by vacuum distillation.

[0059] (7) 115 g of o-fluo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com