PVC foam antibacterial board and preparation method thereof

An antibacterial board, PVC resin powder technology, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problems of easy loosening and falling off of fixing screws, unfavorable environmental protection, low screw holding force, etc. Achieve the effect of low comprehensive use cost, avoid heavy metal pollution, and improve screw holding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The PVC foam antibacterial plate described in the present embodiment 1 is made up of core layer, upper skin layer and lower skin layer, and each layer of raw materials is composed as follows:

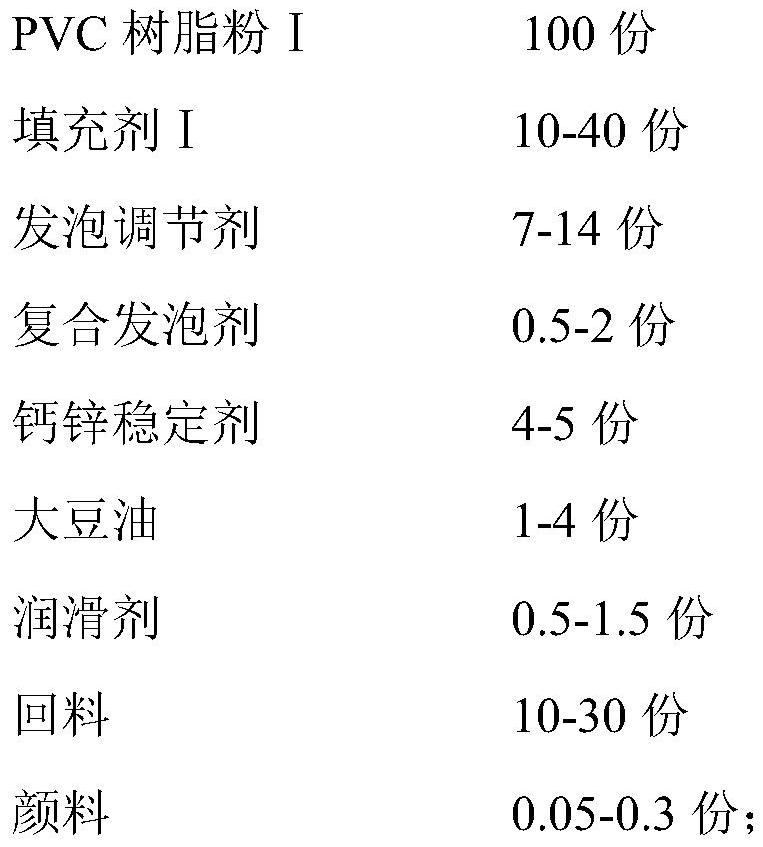

[0041] The core layer is a foamed polyvinyl chloride material, which consists of the following raw materials in parts by weight:

[0042]

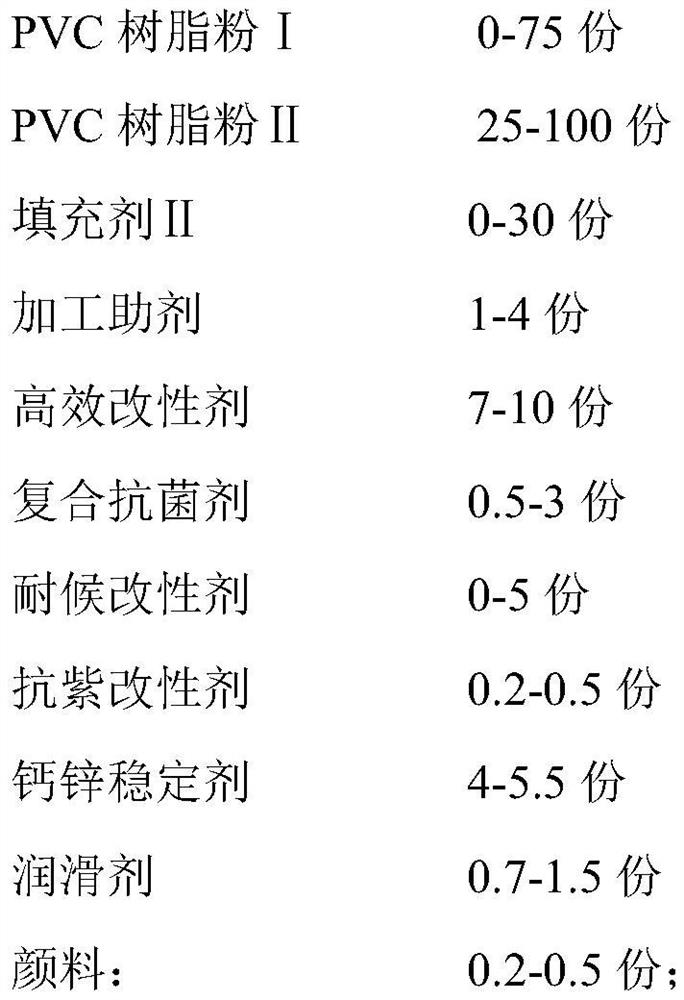

[0043] The upper skin layer and the lower skin layer have the same raw materials, and the skin layer material is composed of the following raw materials in parts by weight:

[0044]

[0045] The composite antibacterial agent is a special antibacterial agent for PVC, which is compounded by an organic antibacterial and antifungal agent and a silver-based inorganic antibacterial agent, and the compounding mass ratio is 1:3.

[0046] PVC resin powder Ⅰ is polyvinyl chloride resin, choose SG-8 type resin.

[0047] PVC resin powder Ⅱ is polyvinyl chloride resin, choose SG-7 type resin.

Embodiment 2

[0071] The PVC foam antibacterial board described in the present embodiment 2 is made up of core layer, upper skin layer and lower skin layer, and each layer of raw materials is composed as follows:

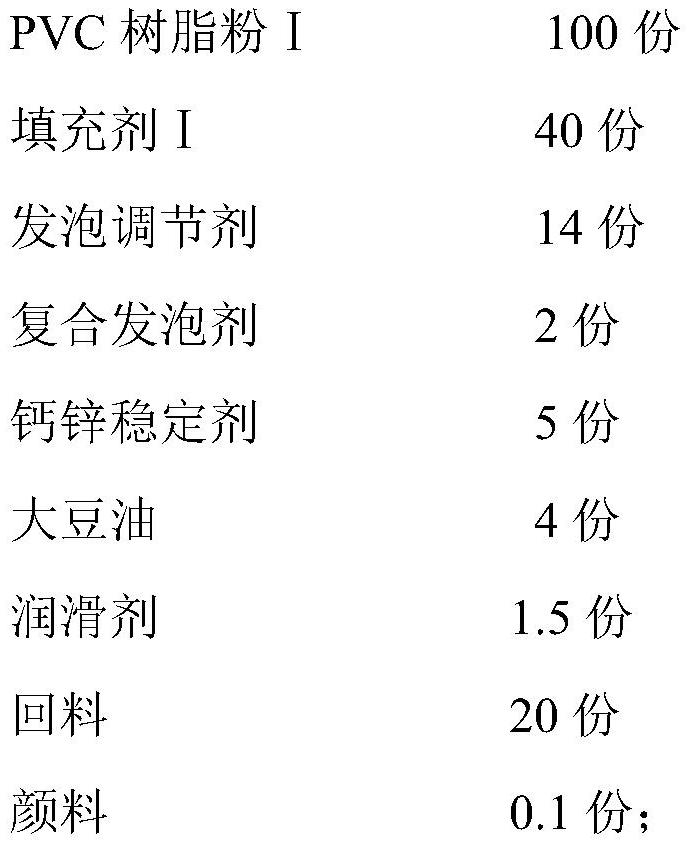

[0072] The core layer is a foamed polyvinyl chloride material, which consists of the following raw materials in parts by weight:

[0073]

[0074]

[0075] The upper skin layer and the lower skin layer have the same raw materials, and the skin layer material is composed of the following raw materials in parts by weight:

[0076]

[0077] The composite antibacterial agent is a special antibacterial agent for PVC, which is compounded by an organic antibacterial and antifungal agent and a silver-based inorganic antibacterial agent, and the compounding mass ratio is 1:6.

[0078] PVC resin powder Ⅰ is polyvinyl chloride resin, choose SG-8 type resin.

[0079] PVC resin powder Ⅱ is polyvinyl chloride resin, choose SG-7 type resin.

[0080] Filler Ⅰ is heavy calcium carbonat...

Embodiment 3

[0092] The PVC foamed antibacterial plate described in this embodiment is composed of a core layer, an upper epidermis and a lower epidermis, and the raw materials of each layer are composed as follows:

[0093] The core layer is a foamed polyvinyl chloride material, which consists of the following raw materials in parts by weight:

[0094]

[0095] The upper skin layer and the lower skin layer have the same raw materials, and the skin layer material is composed of the following raw materials in parts by weight:

[0096]

[0097]

[0098] The composite antibacterial agent is a special antibacterial agent for PVC, which is compounded by organic antibacterial and antifungal agents and silver-based inorganic antibacterial agents, and the compounding mass ratio is 1:8.

[0099] PVC resin powder Ⅰ is polyvinyl chloride resin, choose SG-8 type resin.

[0100] PVC resin powder Ⅱ is polyvinyl chloride resin, choose SG-7 type resin.

[0101] Filler Ⅰ is heavy calcium carbona...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com