PVC wood-plastic foaming antibacterial plate and preparation method thereof

A wood-plastic foaming and antibacterial board technology, applied in the field of PVC plastic sheets, can solve the problems of affecting the market positioning of PVC plastic sheets, limiting the development speed and application scope, and producing mold on the sheets, so as to achieve less visual fatigue and improve the ability to absorb ink. , the effect of reducing the specific gravity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

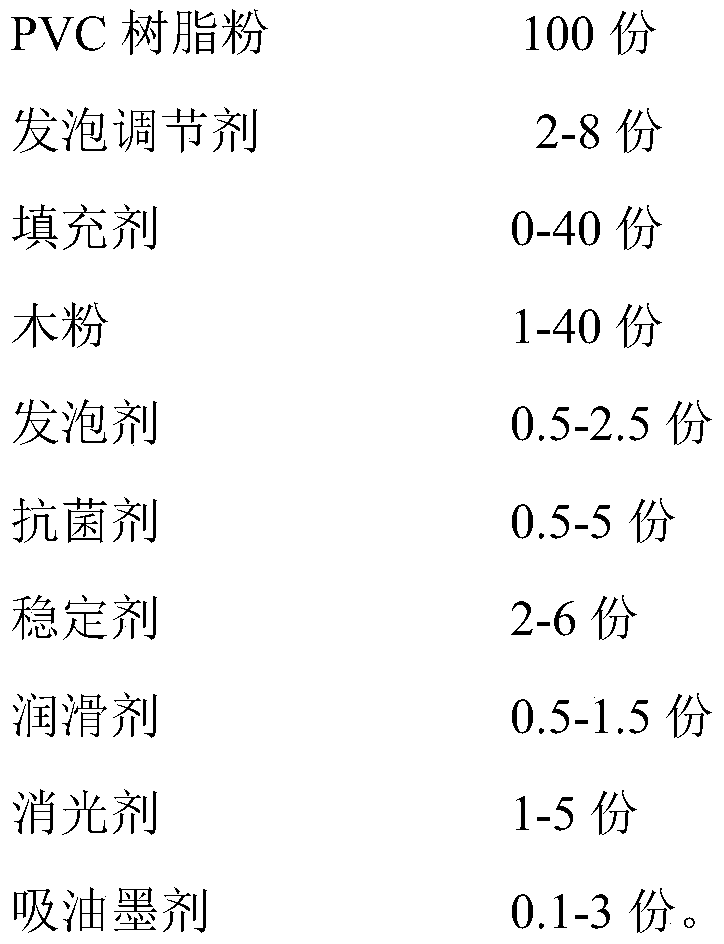

[0032] The PVC wood-plastic foamed antibacterial board described in the present embodiment, in parts by weight, the raw material composition is as follows:

[0033]

[0034] in:

[0035] The PVC resin powder is a mixture of SG-8 and SG-7 resin powders. The composite mass ratio of SG-8 resin powder and SG-7 resin powder is 1:1; the polymerization degree of SG-8 resin powder is 700 , The degree of polymerization of SG-7 resin powder is 800.

[0036] The foam regulator is a mixture of acrylates and styrenes, acrylates are polymers of methyl methacrylate and butyl acrylate, styrenes are polymers of styrene and acrylonitrile, styrene and acrylonitrile The mass ratio of acrylate and styrene is 4:1; the mass ratio of acrylate and styrene is 1:1.

[0037] The filler is heavy calcium carbonate.

[0038] The wood flour is activated Chinese fir flour with a particle size of 100 mesh.

[0039] The foaming agent is a compound of organic yellow foaming agent and inorganic white foami...

Embodiment 2

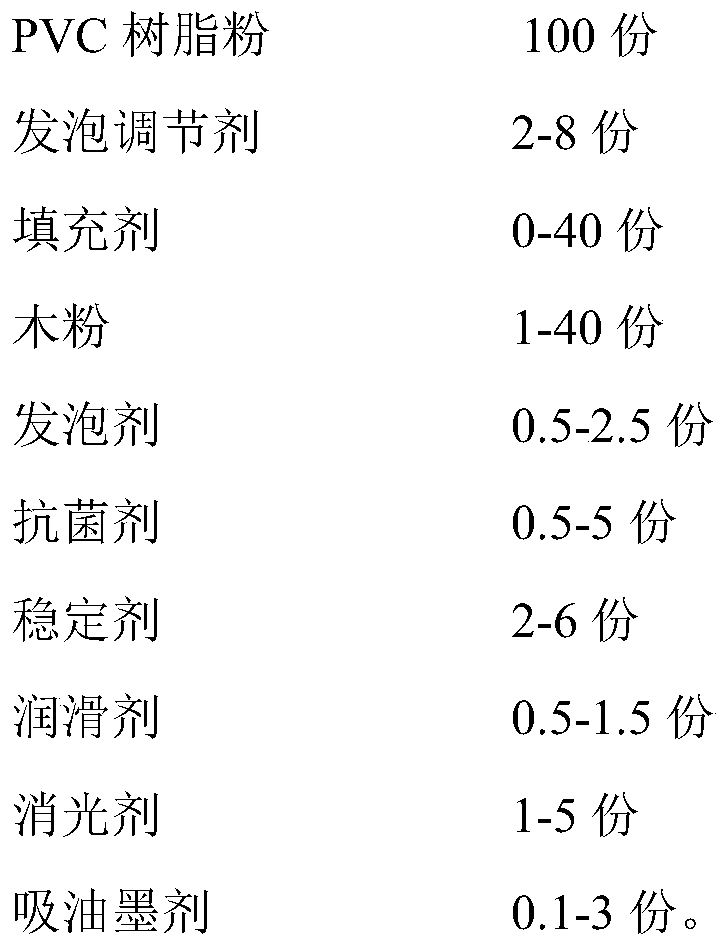

[0053] The PVC wood-plastic foamed antibacterial board described in the present embodiment, in parts by weight, the raw material composition is as follows:

[0054]

[0055]

[0056] in:

[0057] The PVC resin powder is a composite of SG-8 and SG-7 resin powders. The composite mass ratio of SG-8 resin powder and SG-7 resin powder is 1:1; the polymerization degree of SG-8 resin powder is 700, the polymerization degree of SG-7 resin powder is 800.

[0058] The foam regulator is a mixture of acrylates and styrenes, acrylates are polymers of methyl methacrylate and butyl acrylate, styrenes are polymers of styrene and acrylonitrile, styrene and acrylonitrile The mass ratio of acrylates to styrenes is 7:3; the mass ratio of acrylates to styrenes is 2:1.

[0059] The filler is light calcium carbonate.

[0060] The wood flour is activated Chinese fir flour with a particle size of 200 mesh.

[0061] The foaming agent is a compound of organic yellow foaming agent and inorganic w...

Embodiment 3

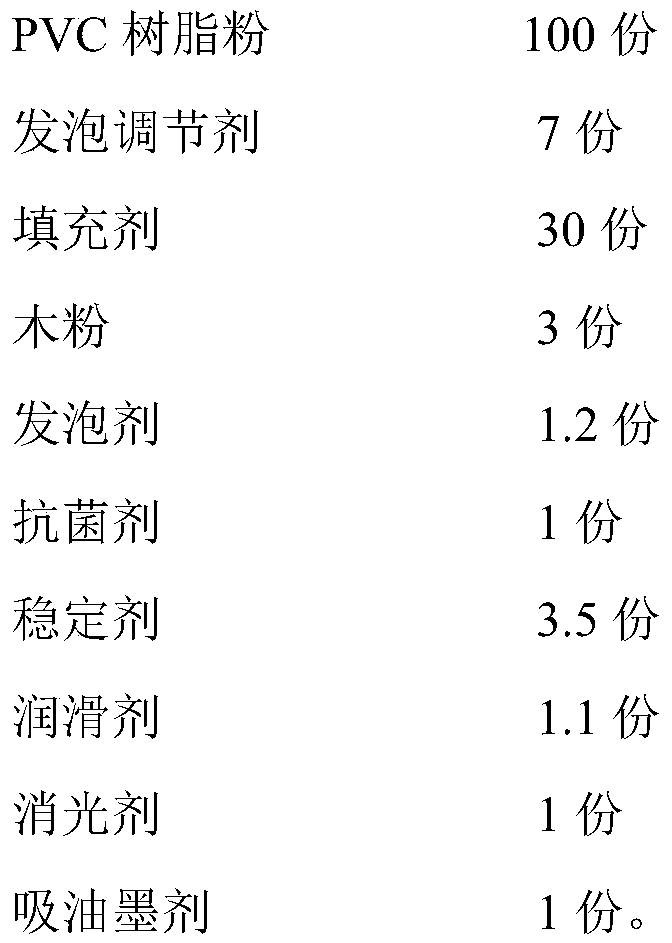

[0075] The PVC wood-plastic foamed antibacterial board described in the present embodiment, in parts by weight, the raw material composition is as follows:

[0076]

[0077] in:

[0078] The PVC resin powder is a mixture of SG-8 and SG-7 resin powders. The composite mass ratio of SG-8 resin powder and SG-7 resin powder is 1:1; the polymerization degree of SG-8 resin powder is 700 , The degree of polymerization of SG-7 resin powder is 800.

[0079] The foam regulator is a mixture of acrylates and styrenes, acrylates are polymers of methyl methacrylate and ethyl acrylate, styrenes are polymers of styrene and acrylonitrile, styrene and acrylonitrile The mass ratio of acrylates and styrenes is 3:1; the mass ratio of acrylates to styrenes is 3:1.

[0080] The filler is heavy calcium carbonate.

[0081] The wood powder is activated poplar wood powder with a particle size of 100 mesh.

[0082] The foaming agent is a compound of organic yellow foaming agent and inorganic white ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com