A kind of stainless steel metallographic etchant and application method thereof

A technology of stainless steel and corrosive agents, which is applied in the preparation of test samples, instruments, and analysis materials, etc., can solve the problems of over-corrosion of powder metallurgy stainless steel, and achieve a smooth and slow corrosion process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] Furthermore, the embodiment of the present invention also provides a method for preparing the metallographic etchant for stainless steel as described above, which is characterized in that it specifically includes the following steps:

[0032] (1) Add concentrated nitric acid solution into absolute ethanol solution to obtain nitric acid alcohol solution;

[0033] At room temperature, slowly add the concentrated nitric acid solution to the absolute ethanol solution from less to more, and at the same time use a cotton swab to dip the nitric acid alcohol solution composed of concentrated nitric acid solution and absolute ethanol solution to wipe the cross section of the solder joint. When the surface of the stainless steel can slightly show some of its grain boundaries, stop adding the concentrated nitric acid solution to complete the configuration of the nitric acid alcohol solution.

[0034] (2) Add ferric chloride solution to nitric acid alcohol solution to obtain metall...

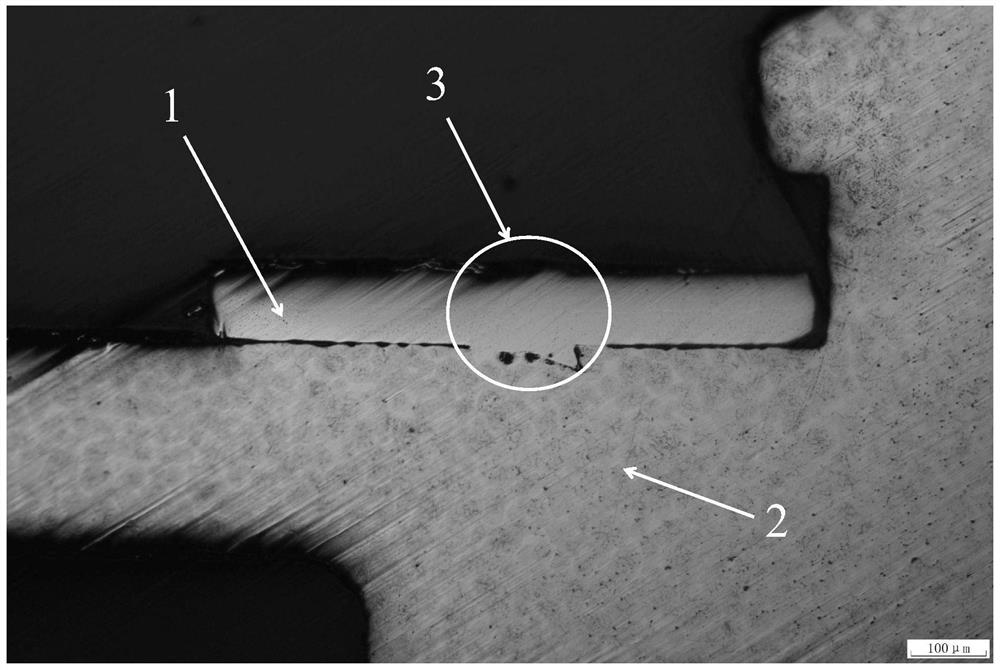

Embodiment 1

[0047] Slowly add concentrated nitric acid solution with a concentration of 65% to the absolute ethanol solution with a concentration of 99.75% from less to more, and at the same time use a cotton swab to dip the nitric acid alcohol solution composed of concentrated nitric acid solution and absolute ethanol solution to wipe the solder joint horizontally When the surface of the powder metallurgy stainless steel can slightly show some of its grain boundaries, stop adding the concentrated nitric acid solution to complete the configuration of the nitric acid alcohol solution. Wherein, the volume fraction of the concentrated nitric acid solution in the nitric alcohol solution is 14.6%, and the volume fraction of the absolute ethanol solution is 85.4%.

[0048]The ferric chloride solution with a mass fraction of 40% is also slowly added to the above-mentioned nitric acid alcohol solution from less to more. , until the phase boundary of the deformed stainless steel and the grain boun...

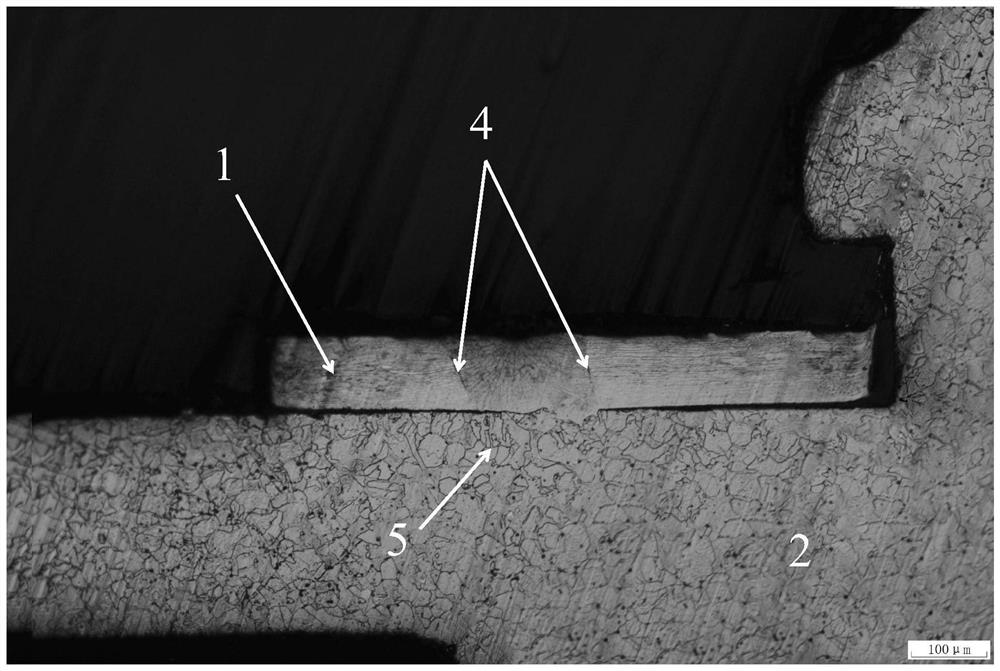

Embodiment 2

[0050] Slowly add concentrated nitric acid solution with a concentration of 68% to the absolute ethanol solution with a concentration of 99.8% from less to more, and at the same time use a cotton swab to dip the nitric acid alcohol solution composed of concentrated nitric acid solution and absolute ethanol solution to wipe the solder joint horizontally When the surface of the powder metallurgy stainless steel can slightly show some of its grain boundaries, stop adding the concentrated nitric acid solution to complete the configuration of the nitric acid alcohol solution. Wherein, the volume fraction of the concentrated nitric acid solution in the nitric alcohol solution is 33.3%, and the volume fraction of the absolute ethanol solution is 66.7%.

[0051] The ferric chloride solution with a mass fraction of 58% is also slowly added to the above-mentioned nitric acid alcohol solution from less to more. , until the phase boundary of the deformed stainless steel and the grain boun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com