Weft insertion device for air-jet loom and automatic adjusting method of weft insertion device

A weft insertion device and air-jet loom technology, which is applied in looms, textiles, textiles and papermaking, etc., can solve the problems of difficult weft yarn arrival, time deviation of weft and weft yarn arrival, less compressed air consumption, etc., and achieve the goal of reducing labor. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Embodiments of the present invention are described below with reference to the accompanying drawings.

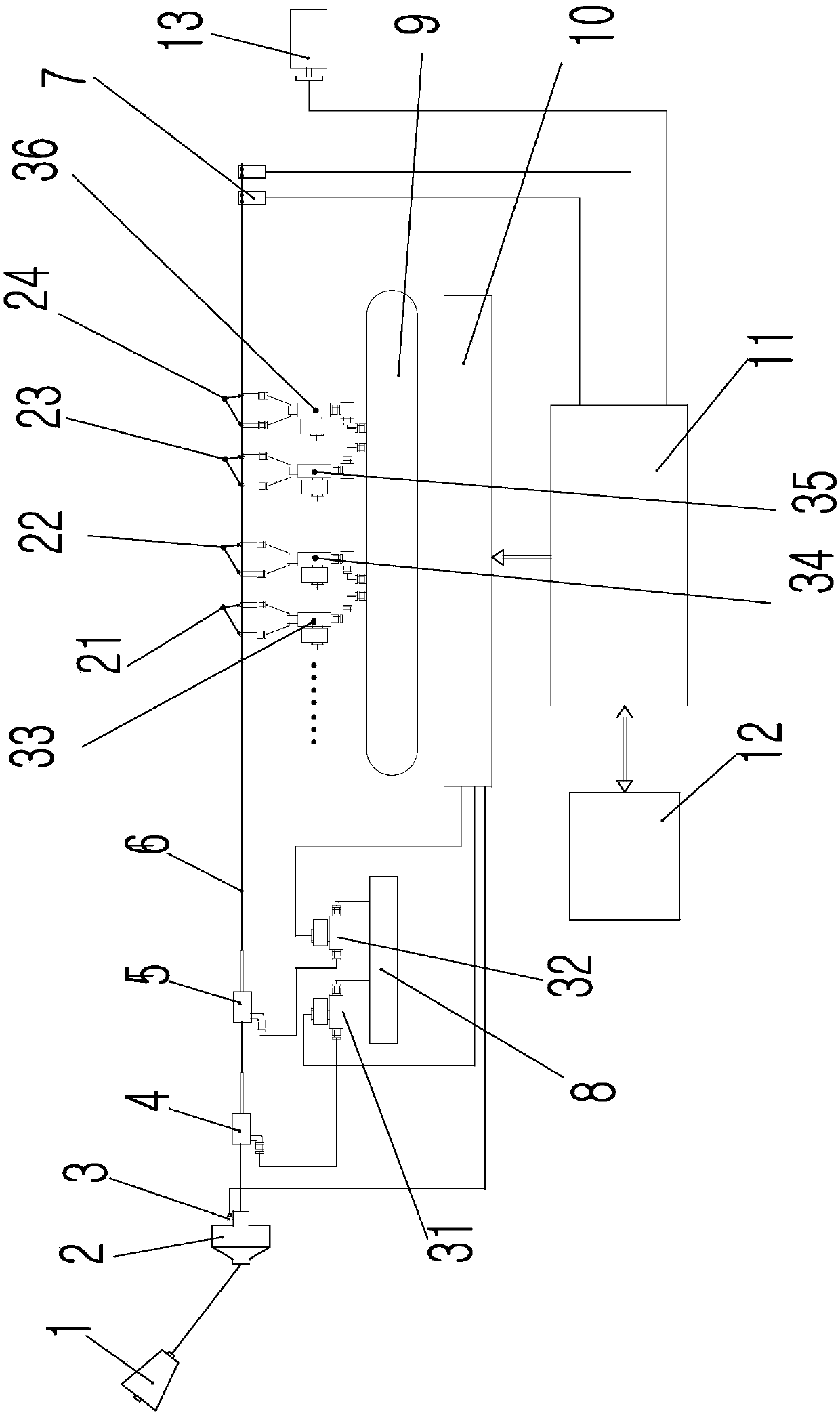

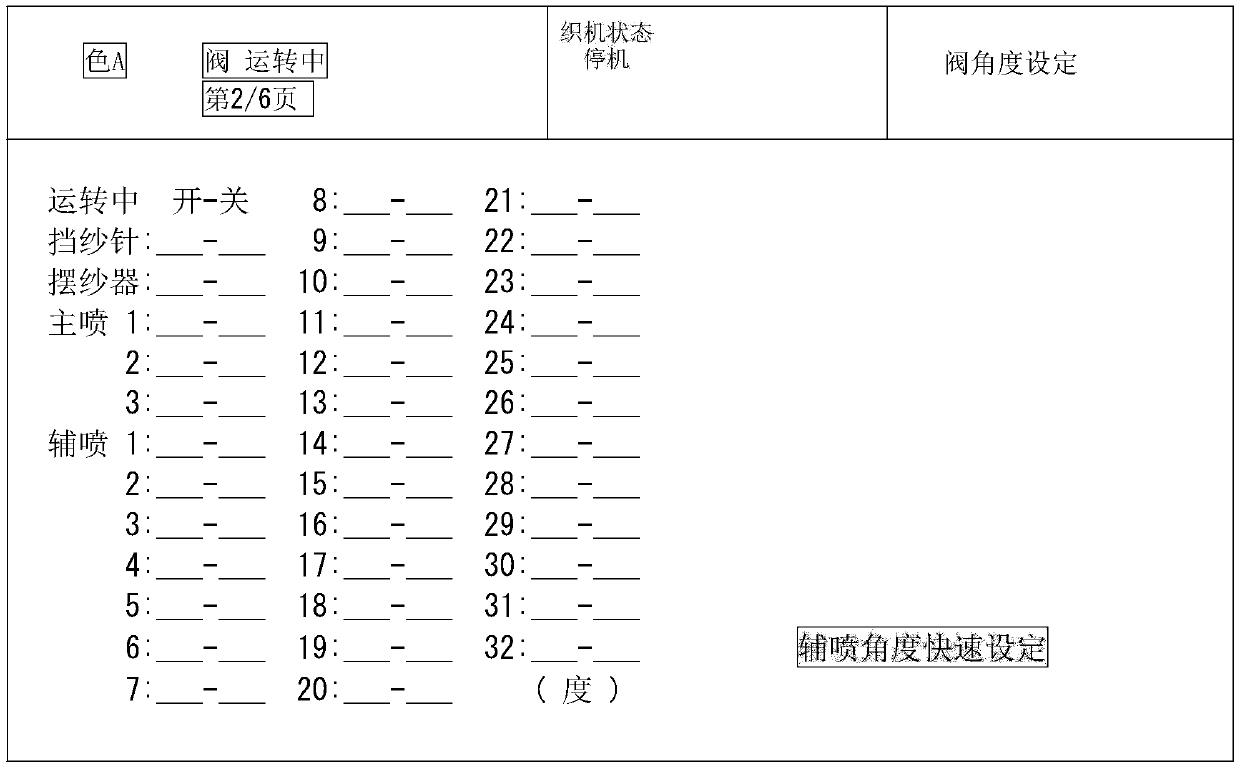

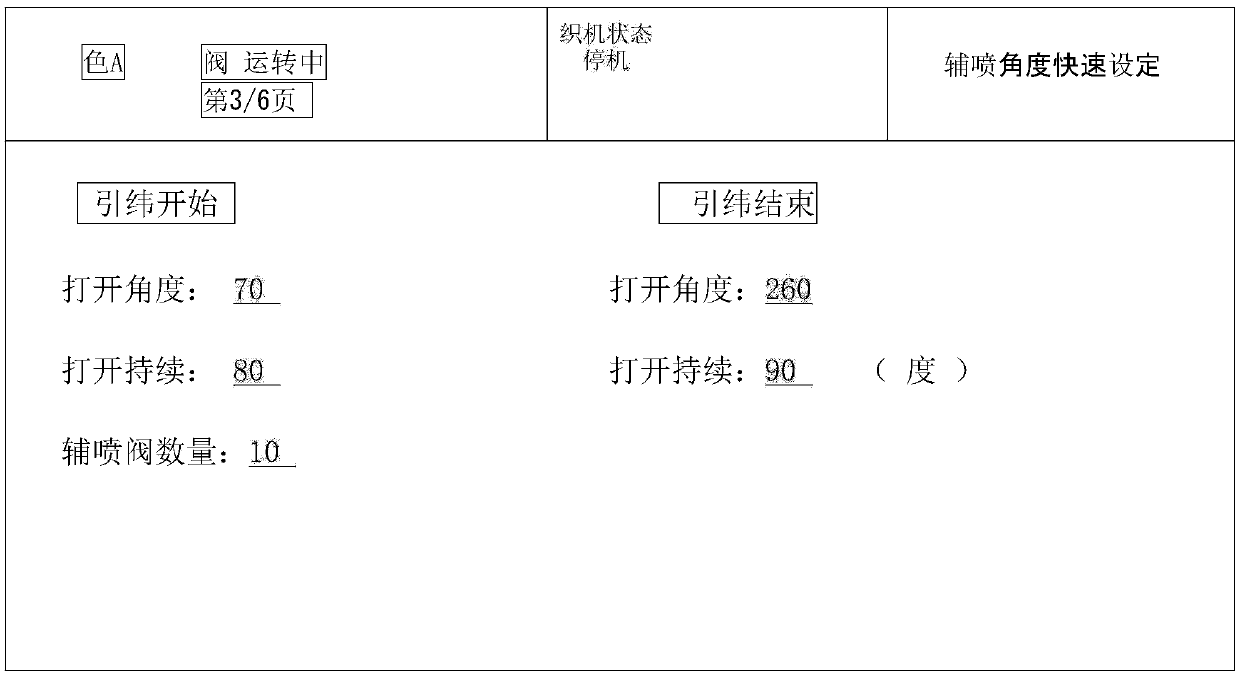

[0041] combine Figure 1 to Figure 7 , a weft insertion device for an air-jet loom, comprising a weft feeder 2, a yarn retaining needle 3, an auxiliary main nozzle 4, a swinging main nozzle, a weft detection detector 7, a main air bag 8, an auxiliary air bag 9, and a solenoid valve control device 10. Main control computer 11, display input device 12, encoder 13, auxiliary nozzles 21-24, auxiliary injection solenoid valves 31-36, multiple auxiliary nozzles 21-24 form an auxiliary nozzle group,

[0042] The main control computer 11 is electrically connected with the electromagnetic valve control device 10, the display input device 12, the encoder 13, and the weft detection detector 7 respectively, and the electromagnetic valve control device 10 is respectively connected with the yarn retaining needle 3, the electromagnetic valve 31, the electromagnetic valve Two 32, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com