Ultra-high molecular polyethylene pipe

An ultra-high polymer, polyethylene pipe technology, applied in the direction of pipes/pipe joints/fittings, pipes, rigid pipes, etc., can solve problems such as easy generation of static electricity, and achieve the effect of improving antistatic performance and improving impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

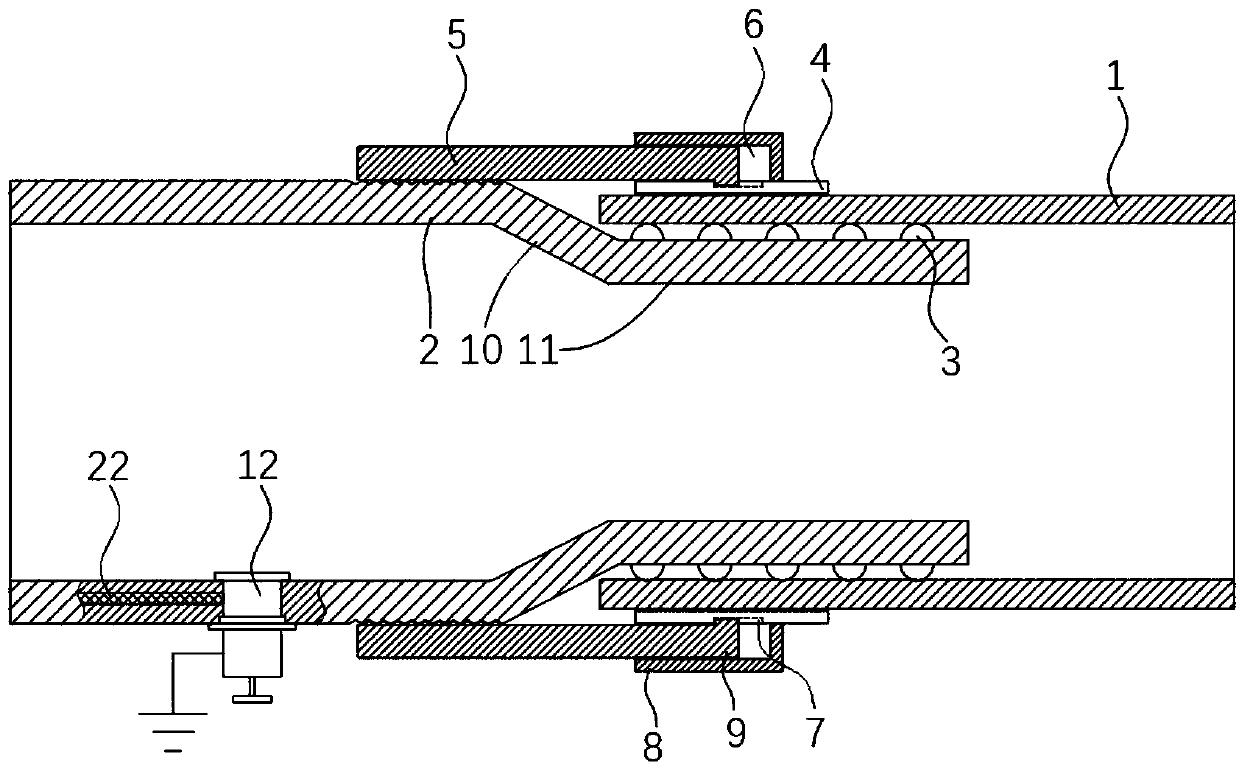

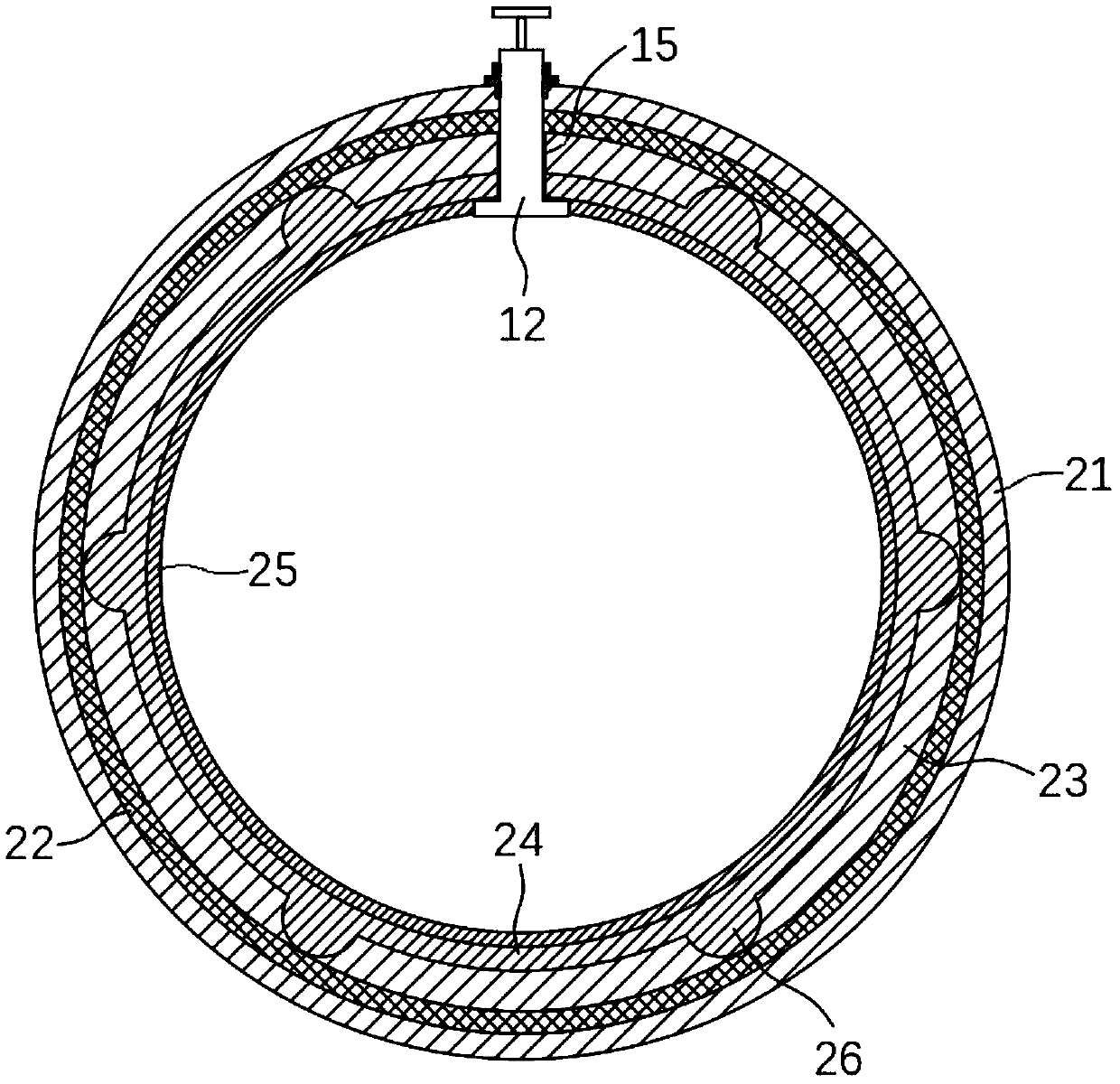

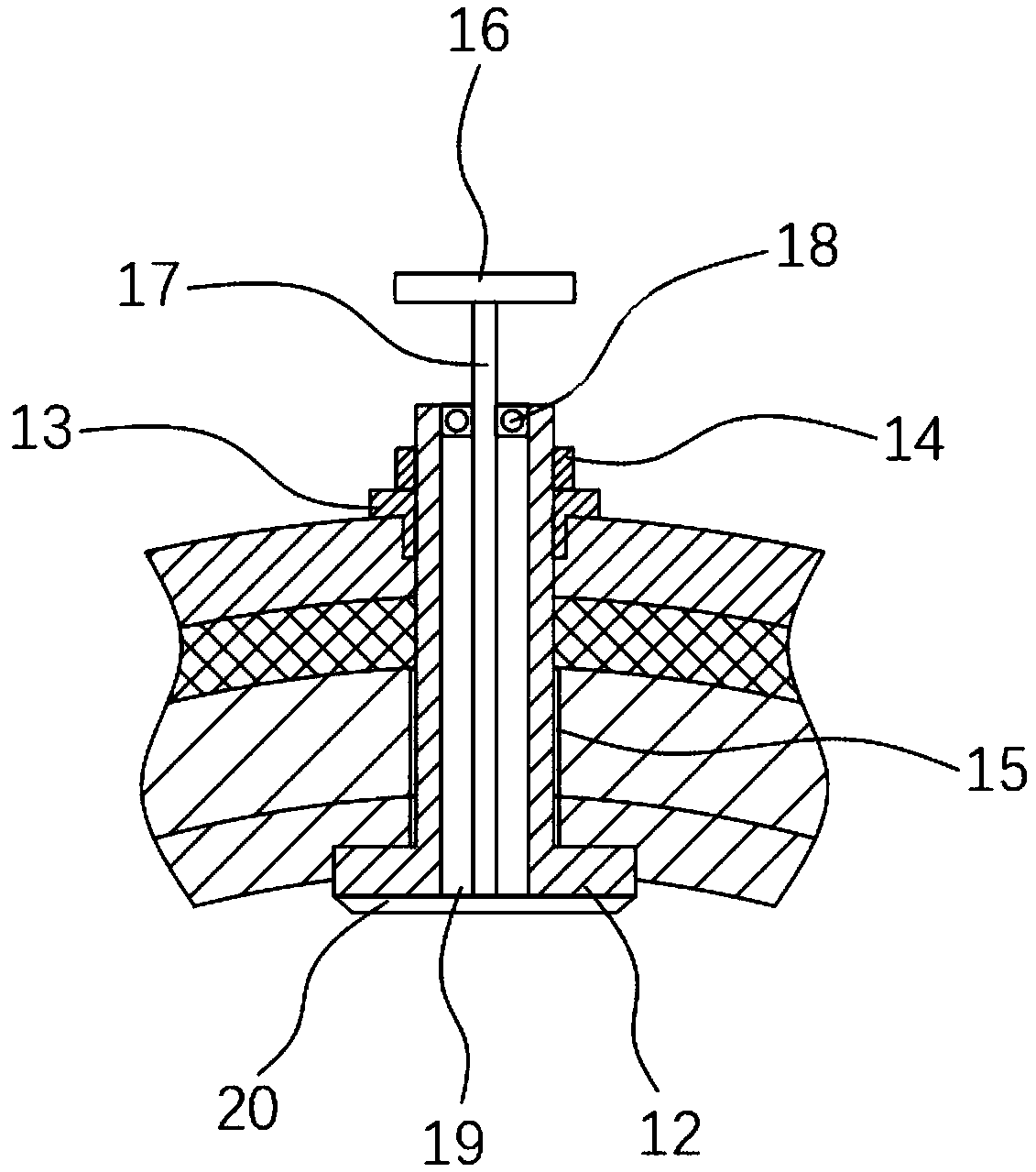

[0023] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0024] refer to Figure 1 to Figure 3 , a kind of ultrahigh molecular weight polyethylene pipe, comprises steel pipe 1 and ultrahigh molecular weight pipe 2, and ultrahigh molecular weight pipe 2 comprises first high molecular layer 21, metal net layer 22, adhesive layer 23, second high molecular layer 24, Antistatic coating 25;

[0025] Specifically, both the first polymer layer 21 and the second polymer layer 24 are made of ultra-high molecular polyethylene material, wherein the metal mesh layer 22 can improve the impact resistance and deformation resistance of the pipeline on the one hand, and can improve the pipeline's performance on the other hand. Antistatic p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com