Composite material image quality indicator and industrial CT detection quality judgment method

A technology of composite materials and determination methods, which is applied in measurement devices, analytical materials, material analysis using wave/particle radiation, etc. problem, to achieve the effect of intuitive and efficient judgment method, low cost, and reduced detection cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

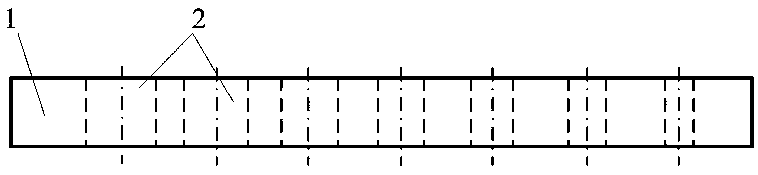

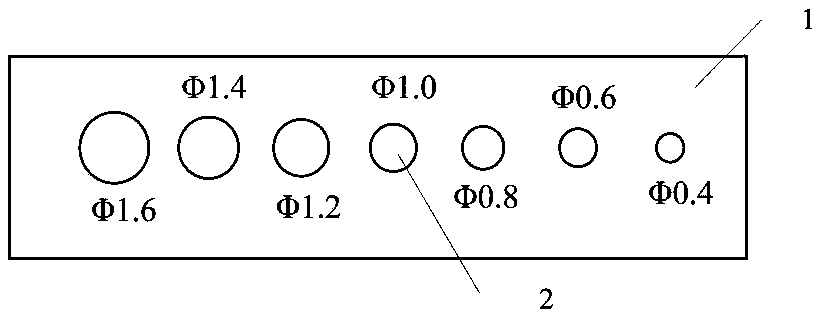

[0051] As shown in Figure 1, the composite material image (hole-type image quality meter) is composed of a substrate 1 and through holes 2 of different diameters processed on the substrate, such as Figure 1a As shown in and b, the diameter of the through hole decreases from left to right, and the distance between any adjacent through holes is larger than the diameter of the adjacent through hole, and the diameter of the through hole gradually decreases from 1.6mm to 0.4mm. It can be used to detect composite material products with holes and inclusion defects with a diameter of 0.4mm or more.

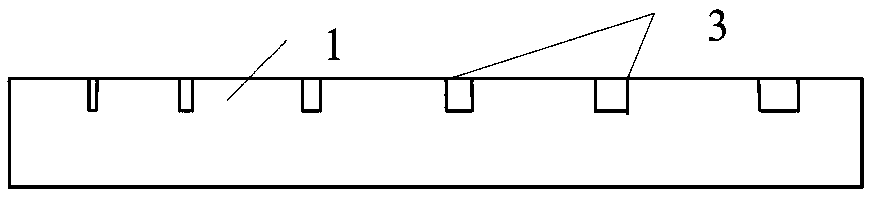

[0052] As shown in FIG. 2 , the composite image (groove image quality meter) consists of a substrate 1 and air gaps 3 of different widths processed on the substrate. Such as Figure 2a As shown in , b, the arrangement width of the gaps increases sequentially from left to right, and the distance between any adjacent gaps is greater than the width of adjacent gaps. The width of the air g...

Embodiment 2

[0054] A certain composite material product requires the detection of holes and inclusion defects with a diameter of more than 0.8mm, as well as delamination and crack defects with a width of more than 0.2mm, and the slice thickness is not greater than 0.2mm.

[0055] The quality determination method includes the following steps:

[0056] 1. Prepare hole-type image quality meter and groove-type image quality meter

[0057] The hole-type image quality meter is similar to that shown in Figure 1. The minimum hole diameter on the hole-type image quality meter is 0.2mm, and the groove-type image quality meter is similar to that shown in Figure 2. The minimum air gap width on the hole-type image quality meter is 0.2mm, which meets the detection requirements of composite products, and can be used for industrial CT detection of this kind of composite products.

[0058] 2. Place the image quality meter on the position of the industrial CT slice that needs to be detected on the product...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com