Out-of-focus low-sensitivity and process window enhancement light source-mask batch optimization method

A technology of process window and optimization method, which is applied in the field of integrated circuit design and lithography resolution enhancement, and can solve problems such as difficulty in directly improving uniformity and consistency, limited ability to compensate defocus error, and low robustness of focus shift , achieve good optimization effect and optimization efficiency, relax error tolerance, and improve the effect of process window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

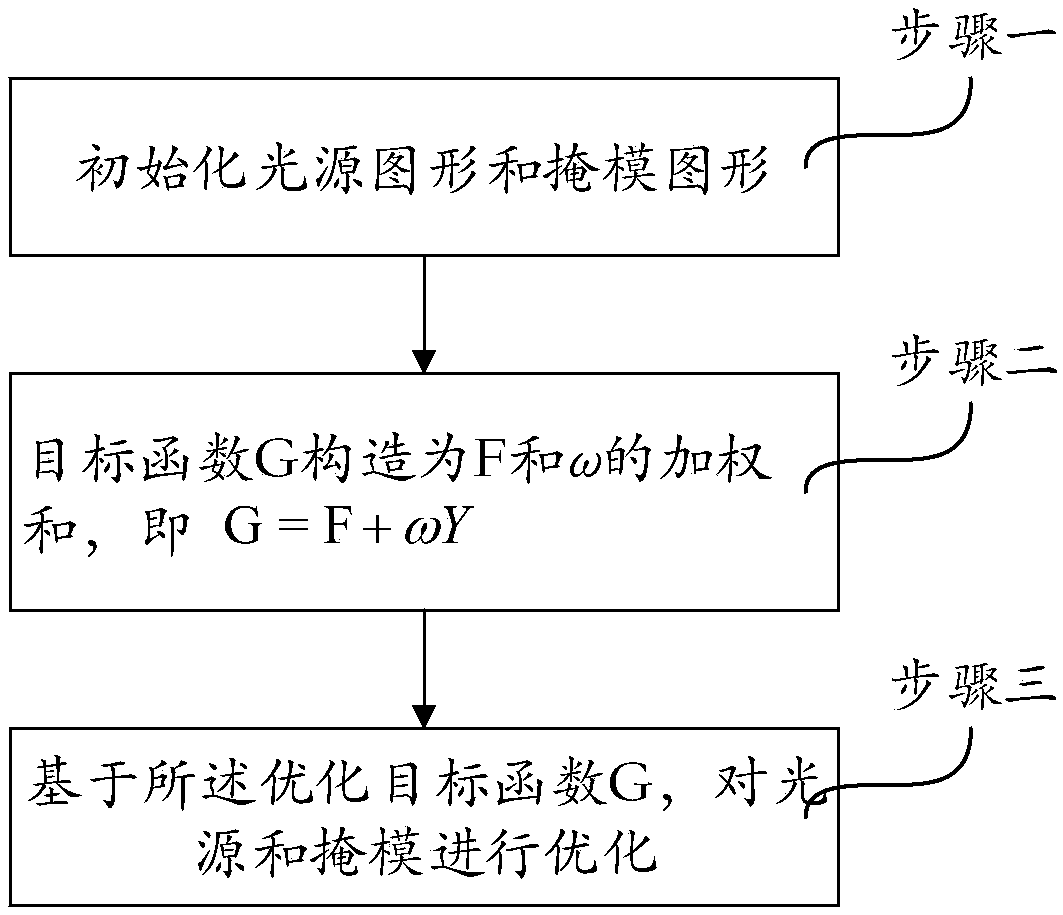

[0039] Such as figure 1 As shown, a light source-mask batch optimization method with low defocus sensitivity and enhanced process window, the specific process is:

[0040] Step 1. Initialize the light source pattern and mask pattern;

[0041] Step 2, constructing the optimization objective function G:

[0042] Let F be the imaging fidelity function, which is defined as the square of the Euler distance between the image in the photoresist corresponding to the target pattern and the current light source pattern and mask pattern, that is in is the target photoresist pattern, Z(β i ) represents the defocus amount β of the photoresist corresponding to the current light source pattern and mask pattern calculated by the vector imaging model i Imaging at time; where, β i is a random defocus variable that obeys a uniform distribution, is the mathematical expectation, Represents the binorm of a matrix.

[0043] The penalty function of the sensitivity term of the imaging resu...

Embodiment 2

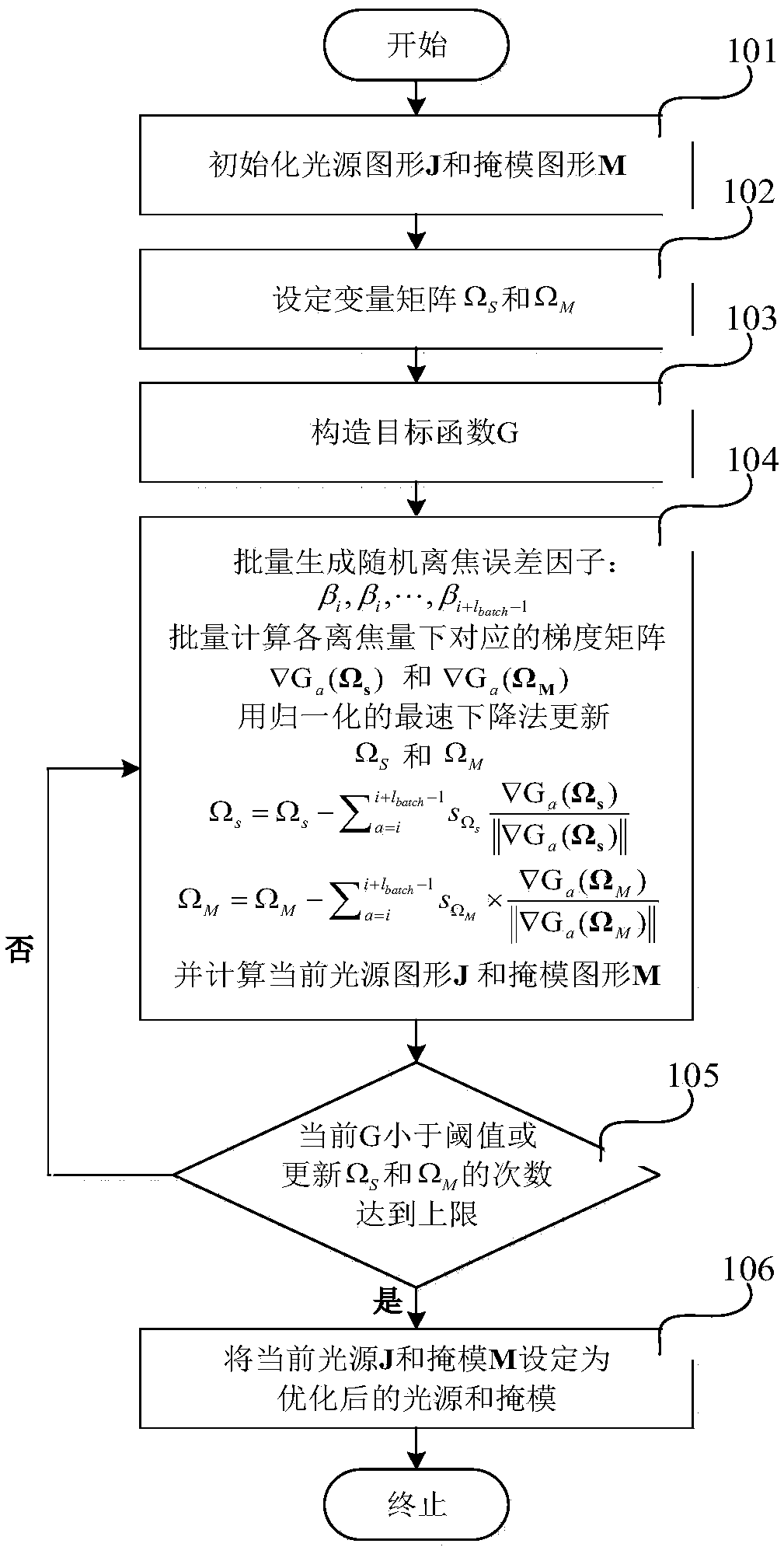

[0048] Such as figure 2 As shown, this embodiment establishes a multi-target light source-mask batch optimization method for low sensitivity to defocus, and the specific steps are:

[0049] (1), initialize the size of the light source to N S ×N S The light source pattern J, the mask pattern M is initialized to a target pattern with a size of N×N where N S and N are integers.

[0050] (2), set the pixel value of the luminous area on the initial light source graphic J to 1, and the pixel value of the non-luminous area to 0; set the size to N S ×N S The light source variable matrix Ω s : When J(x s ,y s )=1, When J(x s ,y s )=0, where J(x s ,y s ) represents each pixel on the light source graph (x s ,y s ) pixel value; set the transmittance of the initial mask pattern M to 1 in the light-transmitting area, and 0 in the light-blocking area; set the mask variable matrix Ω with a size of N×N M : When M(x,y)=1, When M(x,y)=0, Among them, M(x, y) represents th...

Embodiment

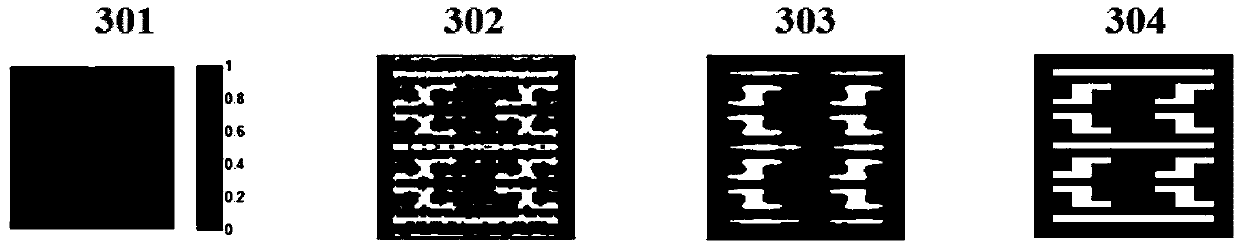

[0095] Such as image 3 Optimized light source patterns, mask patterns and their corresponding photoresist in defocused conditions for related technologies (CN 102692814 B, 2013.09.11) (hereinafter referred to as initial SMO) (optimization is only performed under nominal photolithography conditions) picture. Shown is a schematic of the initial light source, the initial mask and its corresponding imaging in the photoresist. exist image 3 Among them, 301 is an optimized light source pattern, and different colors represent different normalized intensity distributions of the light source. 302 is the optimized mask pattern, which is also the target pattern, white represents the light-transmitting area, black represents the light-blocking area, and its characteristic size is 45nm. In the case of a defocus of 90nm, 303 is an image formed in the photoresist by the photolithography system after using 301 as a light source and 302 as a mask. Comparing the target exposure pattern 30...

PUM

| Property | Measurement | Unit |

|---|---|---|

| optical properties | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com