Rolling bearing fault diagnosis method and system based on particle swarm optimization and medium

A fault diagnosis system and particle swarm optimization technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problem of fault diagnosis methods without particle swarm optimization, fault information characteristics are not obvious, and VMD is difficult to accurately diagnose Results and other issues, to achieve the effect of improving accuracy and fault identification precision, good adaptability, and good noise robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

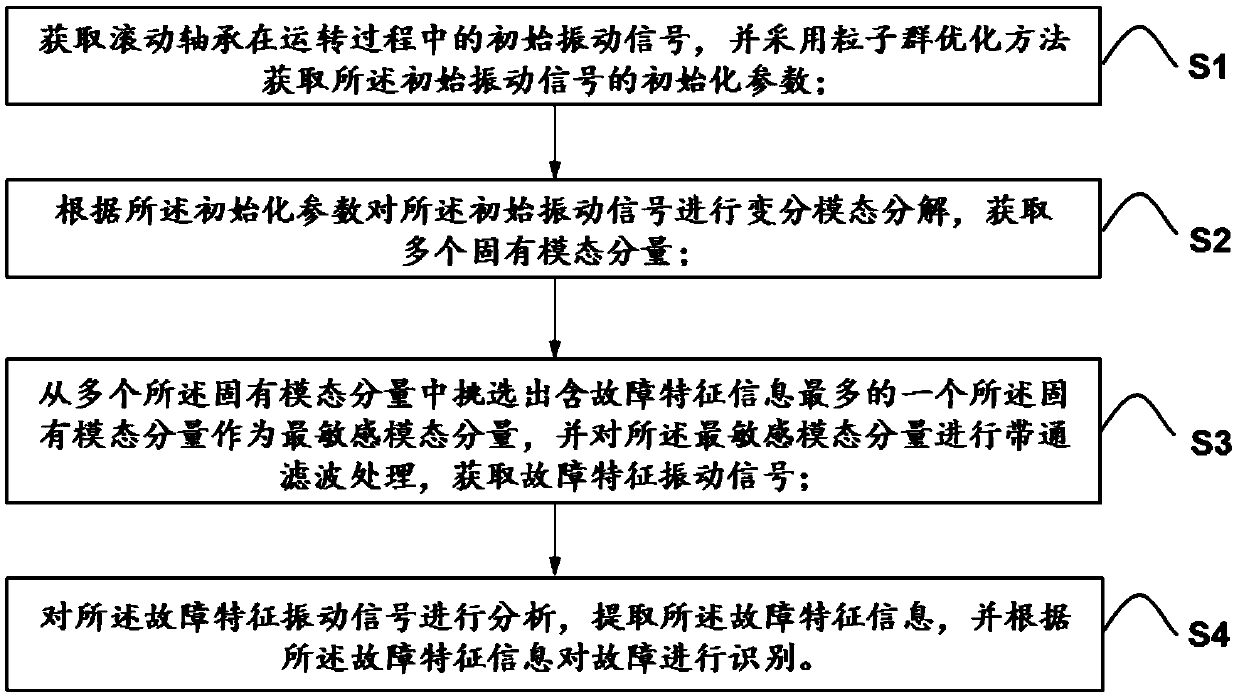

[0080] Example one, such as Figure 1-6 As shown, the fault diagnosis method of rolling bearing based on particle swarm optimization includes the following steps:

[0081] S1: Obtain the initial vibration signal of the rolling bearing during operation, and use the particle swarm optimization method to obtain the initialization parameters of the initial vibration signal;

[0082] S2: Perform variational modal decomposition on the initial vibration signal according to the initialization parameters to obtain multiple natural modal components;

[0083] S3: Select the one with the most fault feature information from the plurality of natural modal components as the most sensitive modal component, and perform band-pass filtering on the most sensitive modal component to obtain Fault characteristic vibration signal;

[0084] S4: Analyze the fault characteristic vibration signal, extract the fault characteristic information, and identify the fault according to the fault characteristic informat...

Embodiment 2

[0139] Embodiment two, such as Figure 7 As shown, Figure 7 This embodiment is a schematic structural diagram of a rolling bearing fault diagnosis system based on particle swarm optimization.

[0140] A rolling bearing fault diagnosis system based on particle swarm optimization, including an acquisition unit 11, a computing unit 12, a variational modal decomposition unit 13, a filter processing unit 14, and an analysis and recognition unit 15;

[0141] The acquisition unit 11 is used to acquire the initial vibration signal of the rolling bearing during operation;

[0142] The computing unit 12 is used to obtain the initialization parameters of the initial vibration signal by adopting a particle swarm optimization method;

[0143] The variational modal decomposition unit 13 is configured to perform variational modal decomposition on the initial vibration signal according to the initialization parameters to obtain multiple natural modal components;

[0144] The arithmetic unit 12 is furt...

Embodiment 3

[0148] Embodiment 3. Based on Embodiment 1 and Embodiment 2, the present invention also discloses another rolling bearing fault diagnosis system based on particle swarm optimization, which includes a processor, a memory, and a processor, a memory, and a memory that can be run in the processor. A computer program on the computer, which implements the following specific steps when the computer program runs:

[0149] S1: Obtain the initial vibration signal of the rolling bearing during operation, and use the particle swarm optimization method to obtain the initialization parameters of the initial vibration signal;

[0150] S2: Perform variational modal decomposition on the initial vibration signal according to the initialization parameters to obtain multiple natural modal components;

[0151] S3: Select the one with the most fault feature information from the plurality of natural modal components as the most sensitive modal component, and perform band-pass filtering on the most sensitiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com