Electrostatic protection structure of image sensor and image sensor

An image sensor and electrostatic protection technology, applied in the direction of circuits, electrical components, electric solid devices, etc., can solve the problems of increasing chip manufacturing costs and increasing chip area, and achieve the effects of improving electrostatic discharge performance, reducing resistance, and increasing chip area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

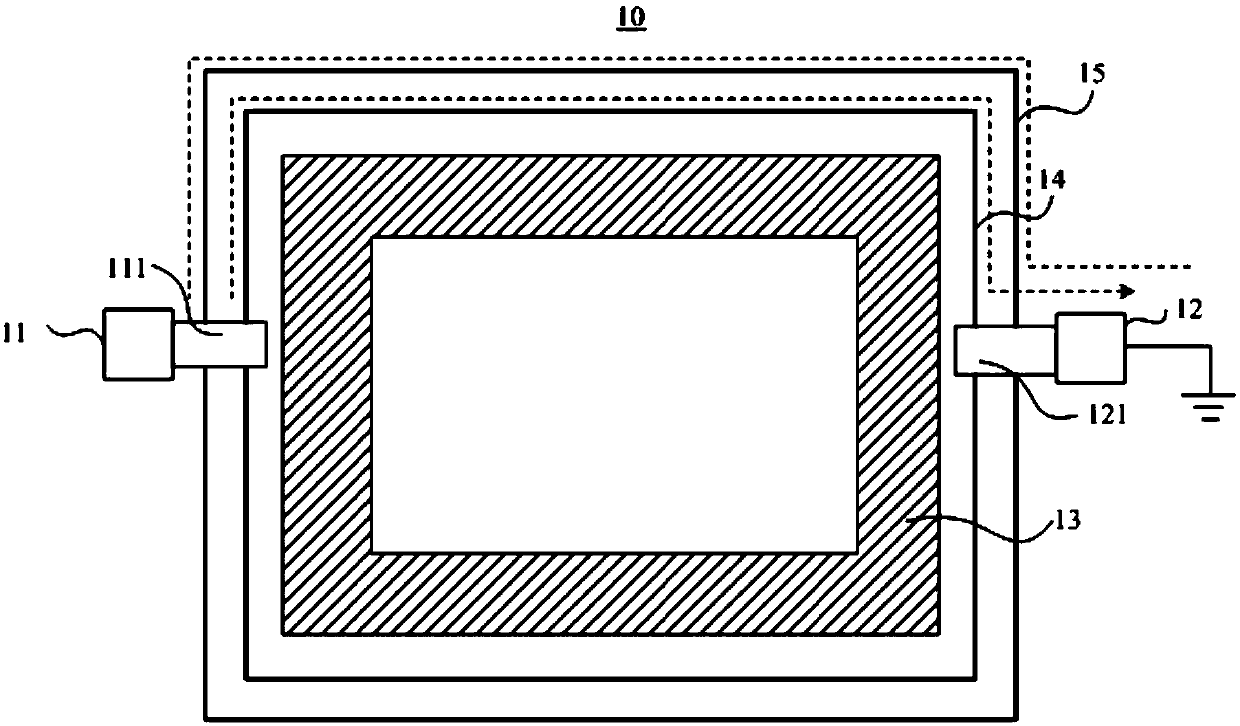

[0042] As mentioned in the background technology, there is a contradiction between the improvement of the electrostatic discharge performance of the existing back-illuminated image sensor and the development trend of chip miniaturization. For details, please refer to figure 1 , figure 1 is a schematic structural diagram of an electrostatic discharge protection circuit of the image sensor 10 .

[0043] In some embodiments, the image sensor 10 may be a CMOS image sensor, including a substrate, and a metal interconnection layer ( figure 1 It can be regarded as a top view of the metal interconnection layer), a plurality of pixel regions are arranged in the substrate, and a pixel peripheral circuit 13 and an electrostatic discharge protection circuit are arranged on the metal interconnection layer, wherein the pixel The peripheral circuit 13 is arranged around the pixel area in the substrate, and the electrostatic discharge protection circuit may include three leakage paths: the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com