High-temperature-resistant foam A-interlayer composite antenna cover and preparation method thereof

A technology of composite materials and radome, which is applied in the direction of antenna, antenna parts, radiating unit cover, etc., to achieve the effects of ensuring manufacturing accuracy, improving structural strength, and reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further elaborated below by describing a preferred specific embodiment in detail in conjunction with the accompanying drawings.

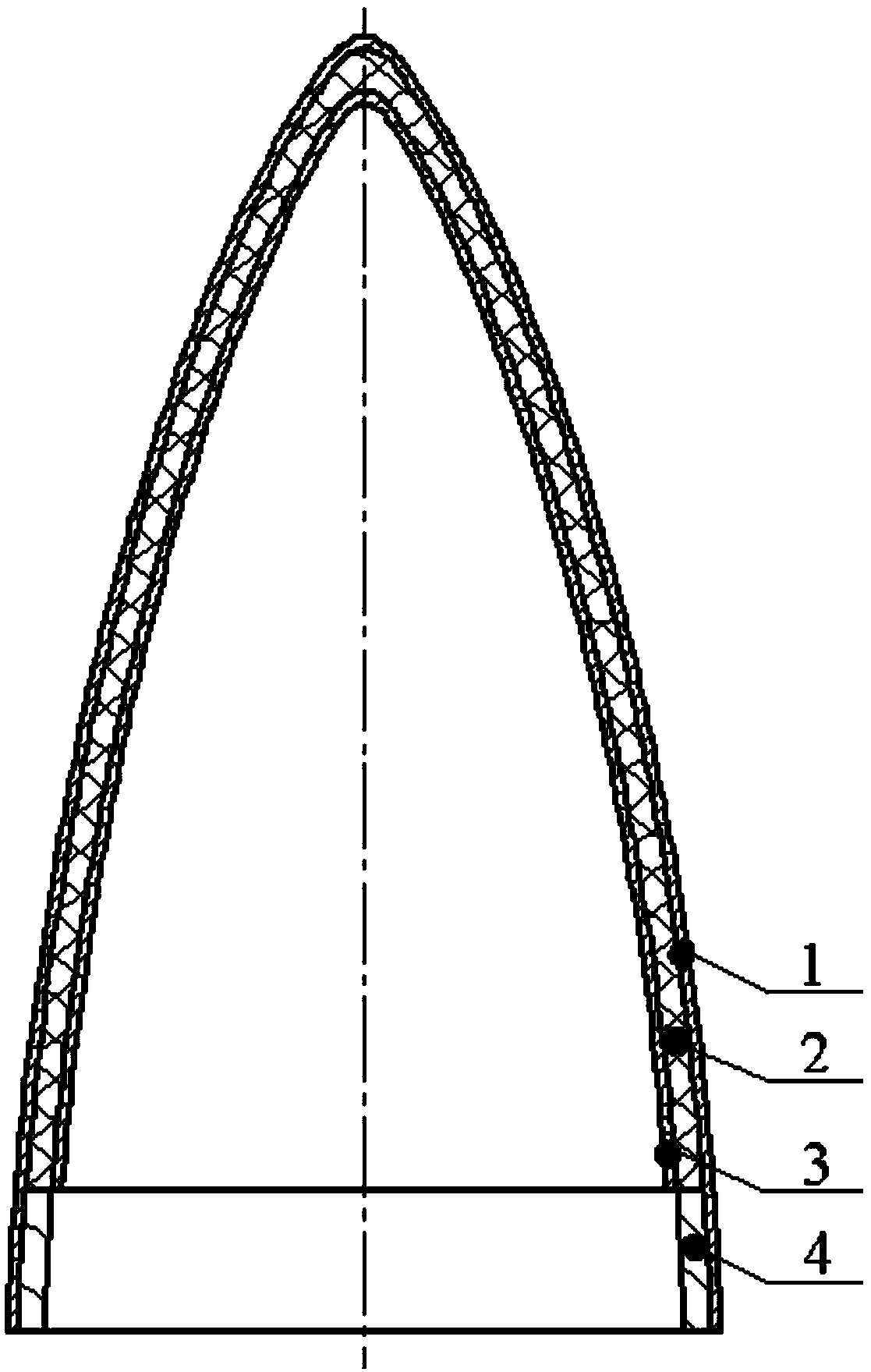

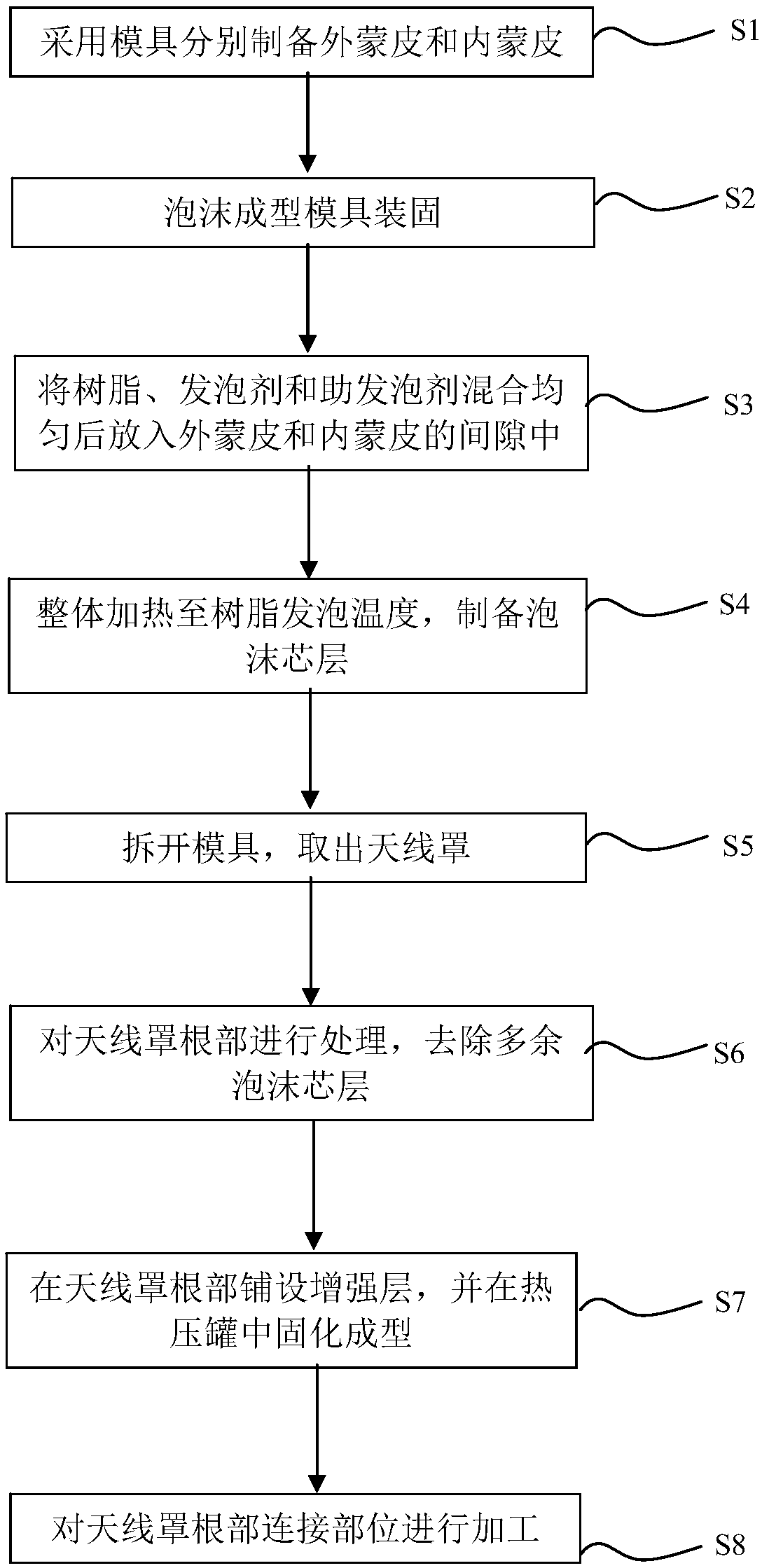

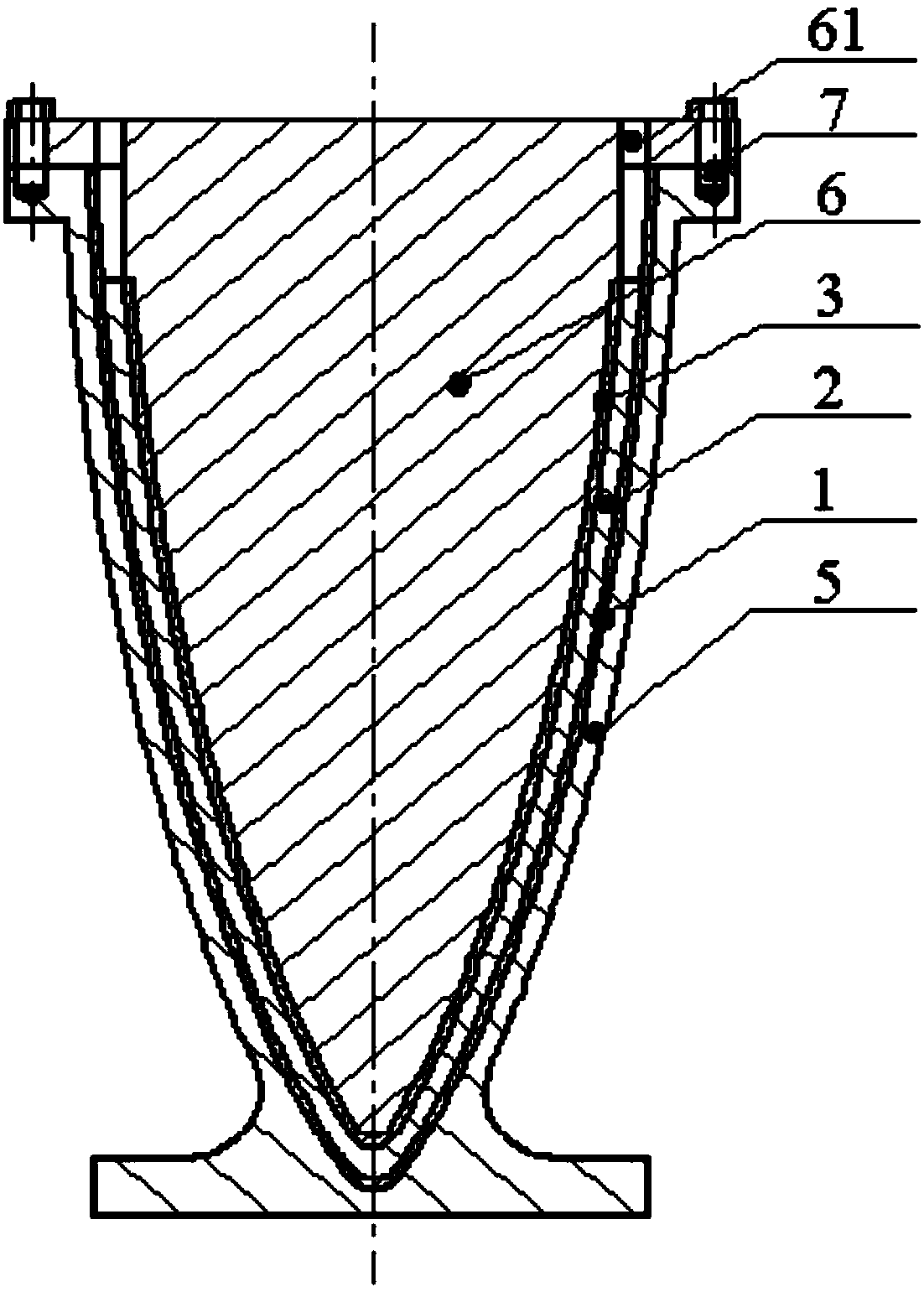

[0036] Such as figure 1 As shown, the high-temperature-resistant foam A sandwich composite radome is composed of an outer skin 1, a foam core 2, an inner skin 3 and a reinforcement layer 4, wherein the foam core 2 is attached to the inner skin 1; the reinforcement layer 4 is set At the bottom of the foam core layer; the outer skin 1 is wrapped around the foam core layer and the reinforcement layer; the outer skin 1, inner skin 3 and reinforcement layer 4 are made of fiber-reinforced resin-based composite materials, and the foam core layer 2 is made of high-temperature-resistant resin Foam.

[0037] In the fiber-reinforced resin-based composite material, the reinforcing fibers include quartz fibers, low-dielectric glass fibers, and high-silica fibers; the resins include silicon-containing aryne resins, polyarylea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com