Activated carbon feeding equipment having environmentally friendly function

A technology of feeding equipment and activated carbon, which is applied in the direction of mixer, gas treatment, membrane technology, etc., can solve the problems affecting the stability of activated carbon feeding, unstable feeding, and inaccurate measurement data collection, etc., to achieve stable transportation and measurement Safety, environmental protection effect guarantee effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

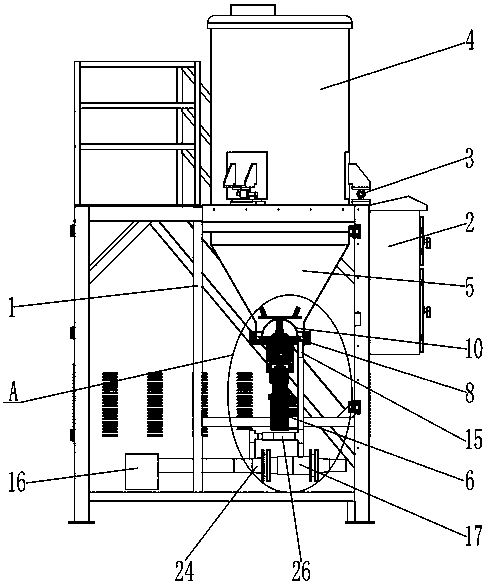

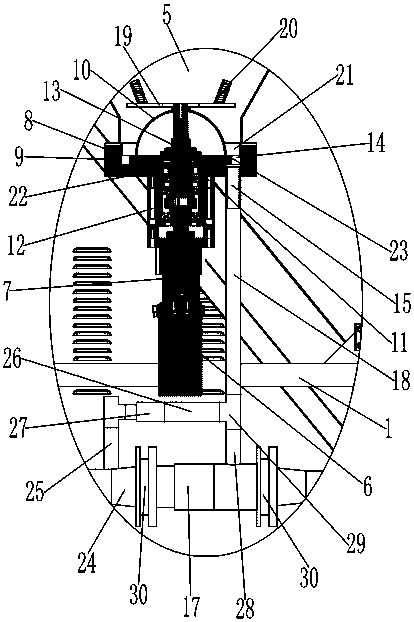

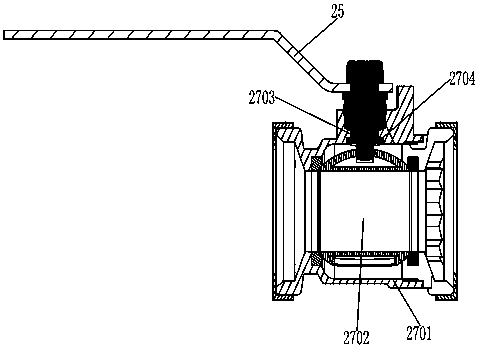

[0023] see Figure 1 to Figure 4 , the present invention provides a kind of activated carbon feeding equipment with environmental protection function, comprising a frame 1, an electric box 2 arranged on one side of the frame 1, and a sensor 3 connected with the electric box 2, a material is arranged above the frame 1 Barrel 4; a hopper 5 that is wide at the top and narrow at the bottom is connected to the bottom of the barrel 4; a motor 6 located directly below the hopper 5 is provided in the frame 1; a speed reducer connected to it is provided above the motor 6 machine 7; the port below the hopper 5 is fixed with a disc feeder 8, and the disc feeder 8 blocks and seals the lower port of the hopper 5; The feeding groove 9; the feeding groove 9 is provided with an inverted hemispherical crushing ball 10, the crushing ball 10 is coaxial with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com