Acid wastewater recovery process

A technology of acid wastewater and process, applied in the direction of heating water/sewage treatment, neutralizing water/sewage treatment, multi-stage water/sewage treatment, etc., can solve the problems of high treatment cost, low treatment cost, and low removal utilization rate, etc. Achieve the effect of simple process and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

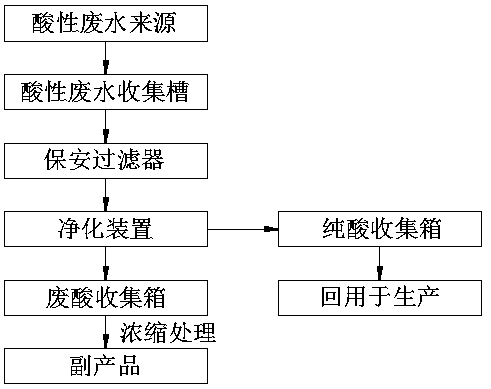

[0022] A kind of acid waste water recovery process, comprises the following steps:

[0023] Step a: collect the high-concentration acid wastewater with a mass percentage concentration of 20% produced in the workshop into the collection tank through the collection pipe;

[0024] Step b: Lift the collected acid wastewater to a security filter with a filter pore size of 1 μm through a lift pump to filter, in order to prevent impurities in the acid from polluting the membrane system;

[0025] Step c: pass the filtered acid wastewater through a purification device equipped with an acid recovery membrane to obtain pure acid and waste acid after purification, the pure acid is directly reused in production, the waste acid is concentrated, neutralized by adding aluminum hydroxide, and then Evaporate and crystallize to obtain the solid water purifying agent as a by-product.

Embodiment 2

[0027] A kind of acid waste water recovery process, comprises the following steps:

[0028] Step a: collect the high-concentration acid wastewater with a mass percentage concentration of 25% produced in the workshop into the collection tank through the collection pipe;

[0029] Step b: Lift the collected acid wastewater through a lift pump to a security filter with a filter pore size of 5 μm for filtration, in order to prevent impurities in the acid from contaminating the membrane system;

[0030] Step c: pass the filtered acid wastewater through a purification device equipped with an acid recovery membrane to obtain pure acid and waste acid after purification, the pure acid is directly reused in production, the waste acid is concentrated, neutralized by adding aluminum hydroxide, and then Evaporate and crystallize to obtain the solid water purifying agent as a by-product.

Embodiment 3

[0032] A kind of acid waste water recovery process, comprises the following steps:

[0033] Step a: collect the high-concentration acid wastewater with a mass percentage concentration of 30% produced in the workshop into the collection tank through the collection pipe;

[0034] Step b: Lift the collected acid wastewater through a lift pump to a security filter with a filter pore size of 10 μm for filtration, in order to prevent impurities in the acid from polluting the membrane system;

[0035] Step c: pass the filtered acid wastewater through a purification device equipped with an acid recovery membrane to obtain pure acid and waste acid after purification, the pure acid is directly reused in production, the waste acid is concentrated, neutralized by adding aluminum hydroxide, and then Evaporate and crystallize to obtain the solid water purifying agent as a by-product.

[0036] The purification device in the above example was purchased from Beijing Shengda Weixin Technology ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap