Leakage plate of 7.5 micrometer electronic yarn drawing equipment

An electronic yarn and wire drawing technology, applied in glass manufacturing equipment, manufacturing tools, etc., can solve the problems of high production cost, fewer leakage plate partitions, low production efficiency, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

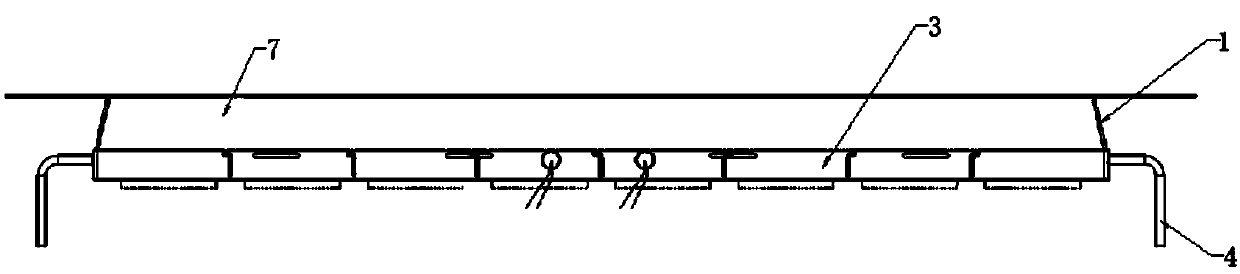

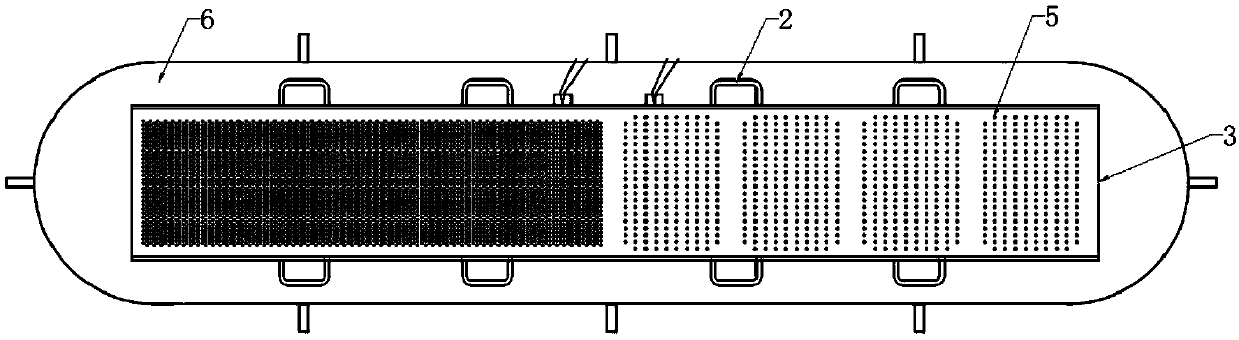

[0034] Such as Figure 1-5 As shown, a leaking plate of a 7.5um electronic yarn drawing equipment includes a plug 1, a bottom plate 3, an electrode 4, a leak nozzle 5 and a side wall 7, and a flow tank is formed between the side wall 7 and the bottom plate 3, and the bottom plate 3 is connected to There are several reinforcing ribs 2, the top of the side wall 7 is welded with a flange 6, the side wall 7 is provided with a thermocouple, and the thermocouple is located outside the flow tank, the electrode 4 is located on the plug 1, and the electrode 4 is located outside the flow tank , the electrode 4 is connected to the thermocouple on the side wall 7 through a couple tube, a number of leakage nozzles 5 are distributed on the bottom plate 3, and two rows of leakage nozzles 5 are arranged in a staggered manner, and a deflector 10 is arranged above the bottom plate 3.

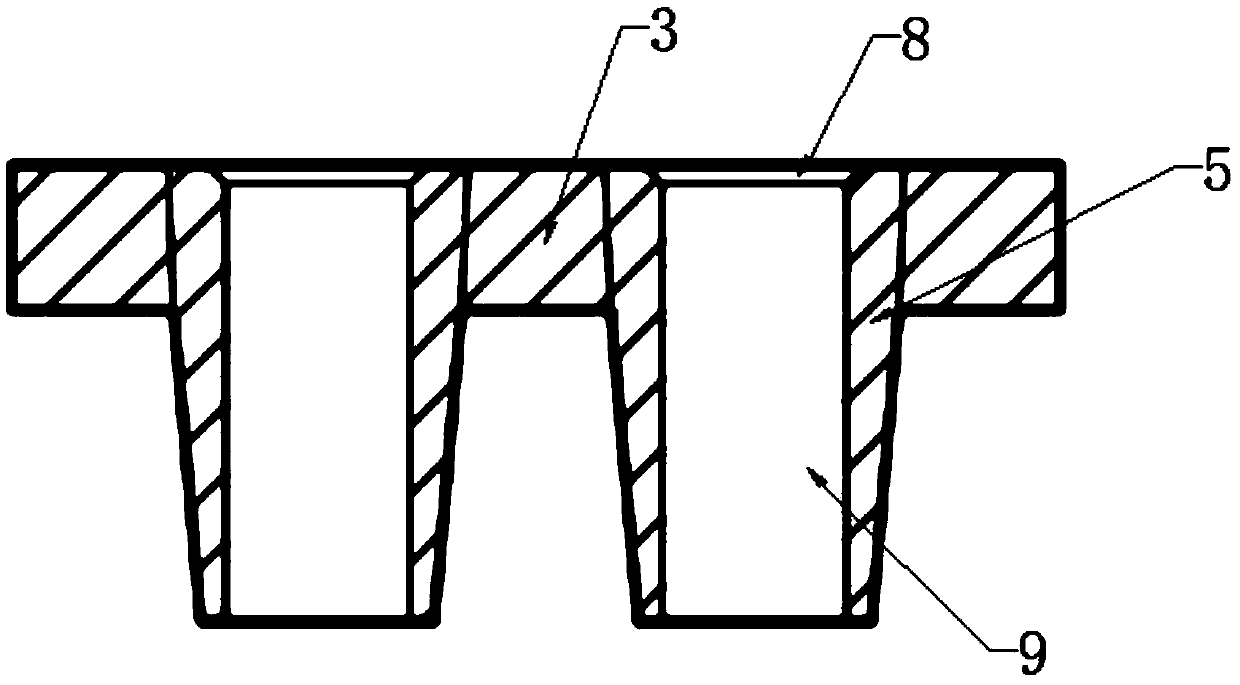

[0035] The inside of the leak nozzle 5 is composed of an upper opening 8 and a lower opening 9, the upper open...

Embodiment 2

[0042] Such as Figure 5-7 As shown, the two ends of the deflector 10 are welded with lifting rods 13, and a number of diversion holes 11 are distributed on the deflector 10. The positions and numbers of the diversion holes 11 correspond to the nozzles 5, and the diversion holes 11 are in the shape of a funnel. shape, and the cross-section formed between two adjacent diversion holes 11 is an inverted V shape, the diversion holes 11 are adapted to the upper opening 8 of the leak nozzle 5, and the diversion holes 11 are set on the upper opening of the leak nozzle 5 within 8.

[0043] The deflector 10 is made of platinum-rhodium alloy, which generally contains 90% Pt and 10% Rh at present, and is strengthened by zirconium dispersion.

[0044] Since the leakage surface of the bottom plate 3 is flat, and the glass liquid has a certain viscosity, it is easy to cause the glass liquid to remain on the bottom plate 3, and the glass liquid will adhere to the leaking nozzle 5 of the lea...

Embodiment 3

[0046] Such as Figure 5-8 As shown, heat sinks 12 are welded between adjacent two rows of leak nozzles 5, and heat sinks 12 are nickel plates 14, and nickel plates 14 are provided with a plurality of through holes in parallel, and the inner diameter of the through holes is equal to the outer diameter of the copper pipe 15, and the copper pipe 15 penetrates into the inside of the nickel plate 14 along the through hole, and one end of the copper pipe 15 is communicated with the water inlet tank 16, and the other end of the copper pipe 15 is communicated with the drain tank 18, and the water inlet tank 16 is connected with the water inlet pipe 17, and the drain tank 18 is connected with drainpipe 19.

[0047] Through the setting of the heat sink 12, since the nickel plate 14 has the performance of high temperature resistance, it can dissipate heat on the leakage plate and the leaked glass fiber, and at the same time penetrate into the nickel plate 14 through the copper tube 15, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com