Boron nitride-strontium feldspar high temperature wave-transparent composite ceramic material and preparation method thereof

A high-temperature wave-transmitting, multi-phase ceramic technology is applied in the field of preparation of ceramic matrix composite materials, which can solve the problems of limited application of strontium feldspar, low density and low thermal expansion coefficient, poor machinability, etc. Processability, effect of improving strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

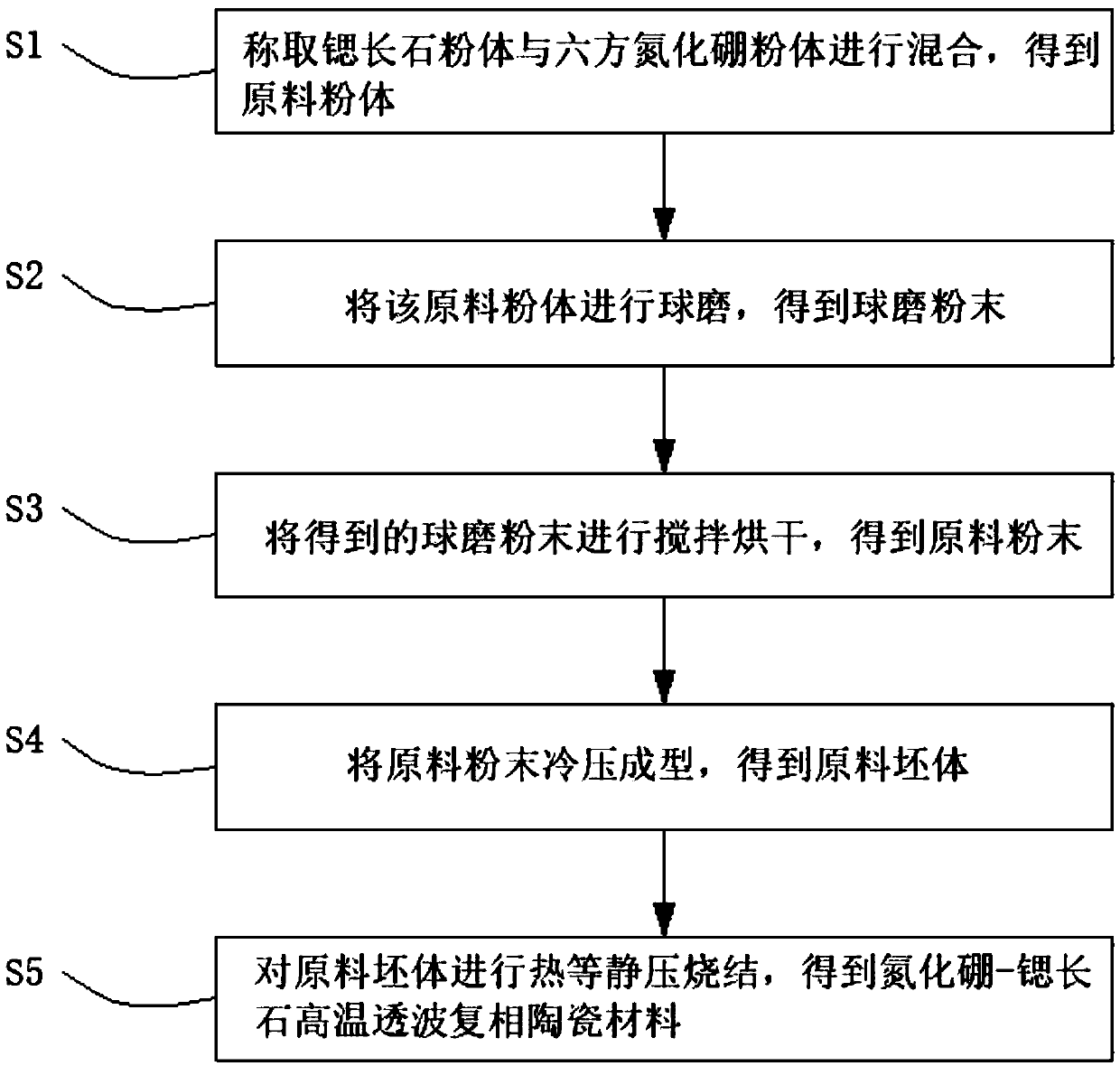

[0033] In order to solve the problem of poor workability of strontium feldspar, the present invention provides a boron nitride-strontium feldspar high-temperature wave-transmitting composite ceramic material and a preparation method of the composite ceramic material, see figure 1 As shown, the preparation method of the boron nitride-strontium feldspar high-temperature wave-transmitting composite ceramic material includes the following steps:

[0034] S1: Weigh and mix strontium feldspar powder and hexagonal boron nitride powder to obtain raw material powder;

[0035] S2: ball mill the raw material powder to obtain ball mill powder;

[0036] S3: Stir and dry the obtained ball mill powder to obtain raw material powder;

[0037] S4: Cold pressing the raw material powder to obtain a raw material body;

[0038] S5: Hot isostatic pressing and sintering of the raw material body to obtain a high-temperature wave-transmitting composite ceramic material of boron nitride-strontium feldspar.

[0039...

Embodiment 1

[0063] This embodiment provides a method for preparing a boron nitride-strontium feldspar high-temperature wave-transmitting composite ceramic material. The preparation method includes:

[0064] S1: Weigh 155.25 g of strontium feldspar powder with a particle size of 200 mesh and 72.45 g of hexagonal boron nitride powder with a particle size of 100 mesh and a purity of 99% by weight and mix them to obtain a raw material powder;

[0065] S2: Place the raw material powder in a polytetrafluoroethylene ball mill tank, use alumina balls, and add absolute ethanol for wet ball milling for 24 hours to obtain ball mill powder;

[0066] S3: Stir and dry the obtained ball mill powder at 60° C. for 24 hours and then pass through a 100 mesh sieve to obtain raw material powder;

[0067] S4: Pour the raw material powder into a steel mold with a diameter of 50 mm and a boron nitride coated inner wall and cold press at a pressure of 15 MPa for 3 minutes to obtain a raw material body;

[0068] S5: Hot iso...

Embodiment 2

[0081] The difference from the first embodiment is that this embodiment provides a method for preparing a boron nitride-strontium feldspar high-temperature wave-transmitting composite ceramic material. The preparation method includes:

[0082] S1: Weigh 16.75 g of strontium feldspar powder with a particle size of 200 mesh and 50.25 g of hexagonal boron nitride powder with a particle size of 100 mesh and a purity of 99% by weight, and mix them to obtain a raw material powder;

[0083] S2: Place the raw material powder in a polytetrafluoroethylene ball mill tank, use alumina balls, and add absolute ethanol for wet ball milling for 24 hours to obtain ball mill powder;

[0084] S3: Stir and dry the obtained ball mill powder at 60° C. for 24 hours and then pass through a 100 mesh sieve to obtain raw material powder;

[0085] S4: Pour the raw material powder into a steel mold with a diameter of 50 mm and a boron nitride coated inner wall and cold press at a pressure of 15 MPa for 3 minutes t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com