Intelligent nano-microsphere profile controlling and flooding oil production improver and preparation method thereof

A nano-microsphere, control and displacement technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of poor foam stability, cross-linking agent is easily absorbed by the formation, and prone to precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

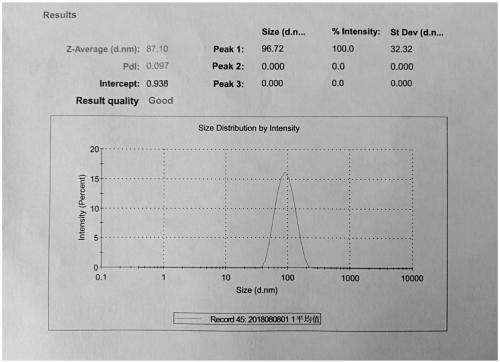

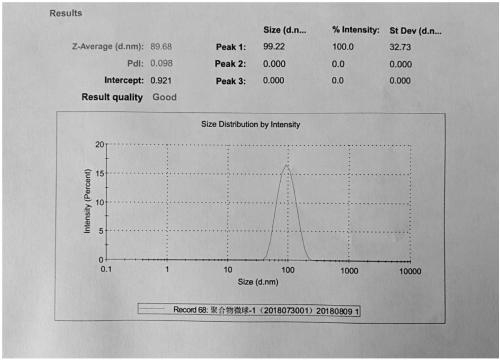

Image

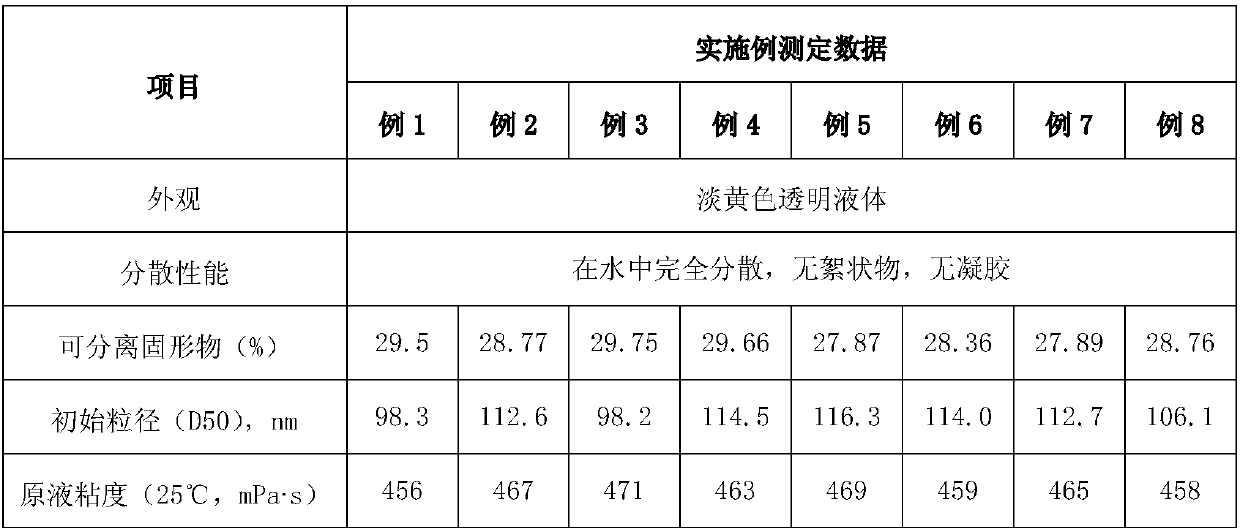

Examples

Embodiment 1

[0023] An intelligent nano-microsphere control and production increase agent is composed of the following raw materials in parts by weight: 30g of kerosene, 10g of emulsifier, 20g of acrylamide, 0.1g of crosslinking agent, 0.1g of initiator, 0.1g of catalyst, 5g of surfactant, and The amount is deionized water, and its total weight part is 100.

[0024] The above emulsifier is a mixture of NP-10, Span 60 and Span 80, and its mass ratio is 1:2:7.

[0025] The above-mentioned crosslinking agent is N,N-methylenebisacrylamide.

[0026] The above-mentioned initiator is ammonium persulfate.

[0027] Above-mentioned catalyst is sodium bisulfite.

[0028] Above-mentioned surfactant is sodium lauryl sulfate.

[0029] The steps of a preparation method of an intelligent nano-microsphere control and production increase agent are as follows:

[0030] 1) Preparation of the oil phase: add 30g of kerosene and 10g of emulsifier into the reactor, and fully stir for 30min at a stirring speed...

Embodiment 2

[0035] An intelligent nano-microsphere control and production increase agent is composed of the following raw materials in parts by weight: 30g of kerosene, 15g of emulsifier, 26g of acrylamide, 0.1g of crosslinking agent, 0.1g of initiator, 0.1g of catalyst, 5g of surfactant, and The amount is deionized water, and its total weight part is 100.

[0036] The above emulsifier is a mixture of NP-10, Span 60 and Span 80, and its mass ratio is 1:2:7.

[0037] The above-mentioned crosslinking agent is N,N-methylenebisacrylamide.

[0038] The above-mentioned initiator is ammonium persulfate.

[0039] Above-mentioned catalyst is sodium metasulfite.

[0040] Above-mentioned surfactant is sodium dodecylbenzenesulfonate.

[0041] The steps of a preparation method of an intelligent nano-microsphere control and production increase agent are as follows:

[0042] 1) Preparation of the oil phase: add 30g of kerosene and 15g of emulsifier into the reactor, and fully stir for 30min at a sti...

Embodiment 3

[0047] An intelligent nano-microsphere control and production increase agent is composed of the following raw materials in parts by weight: 40g of kerosene, 20g of emulsifier, 30g of acrylamide, 0.5g of crosslinking agent, 0.5g of initiator, 0.5g of catalyst, 10g of surfactant, and The amount is deionized water, and its total weight part is 100.

[0048] The above emulsifier is a mixture of NP-10, Span 60 and Span 80, and its mass ratio is 1:2:7.

[0049] The above-mentioned crosslinking agent is N,N-methylenebisacrylamide.

[0050] The above-mentioned initiator is ammonium persulfate.

[0051] Above-mentioned catalyst is sodium bisulfite.

[0052] Above-mentioned surfactant is sodium dodecylbenzenesulfonate.

[0053] The steps of a preparation method of an intelligent nano-microsphere control and production increase agent are as follows:

[0054] 1) Preparation of the oil phase: add 40g of kerosene and 20g of emulsifier into the reactor, and fully stir for 30min at a stirri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com