Improved injection-suction type flue gas cooling mixer for road maintenance and repair

A technology for flue gas cooling and road maintenance, applied in the field of road construction machinery, can solve the problems of inability to adjust the smoke absorption speed, low adjustability, poor cooling effect, etc., so as to avoid conflicts between maintenance and work and achieve cooling effect. , the effect of improving the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

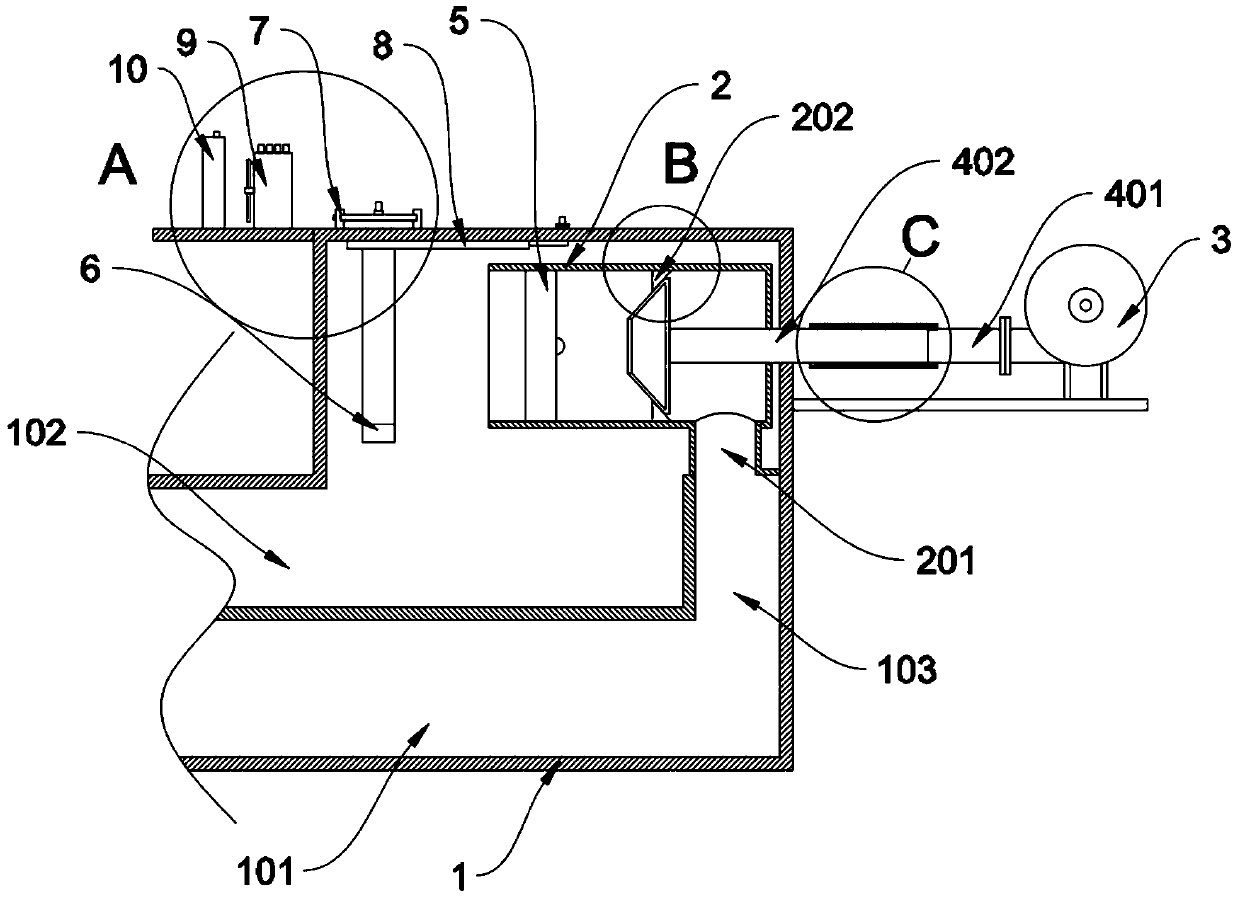

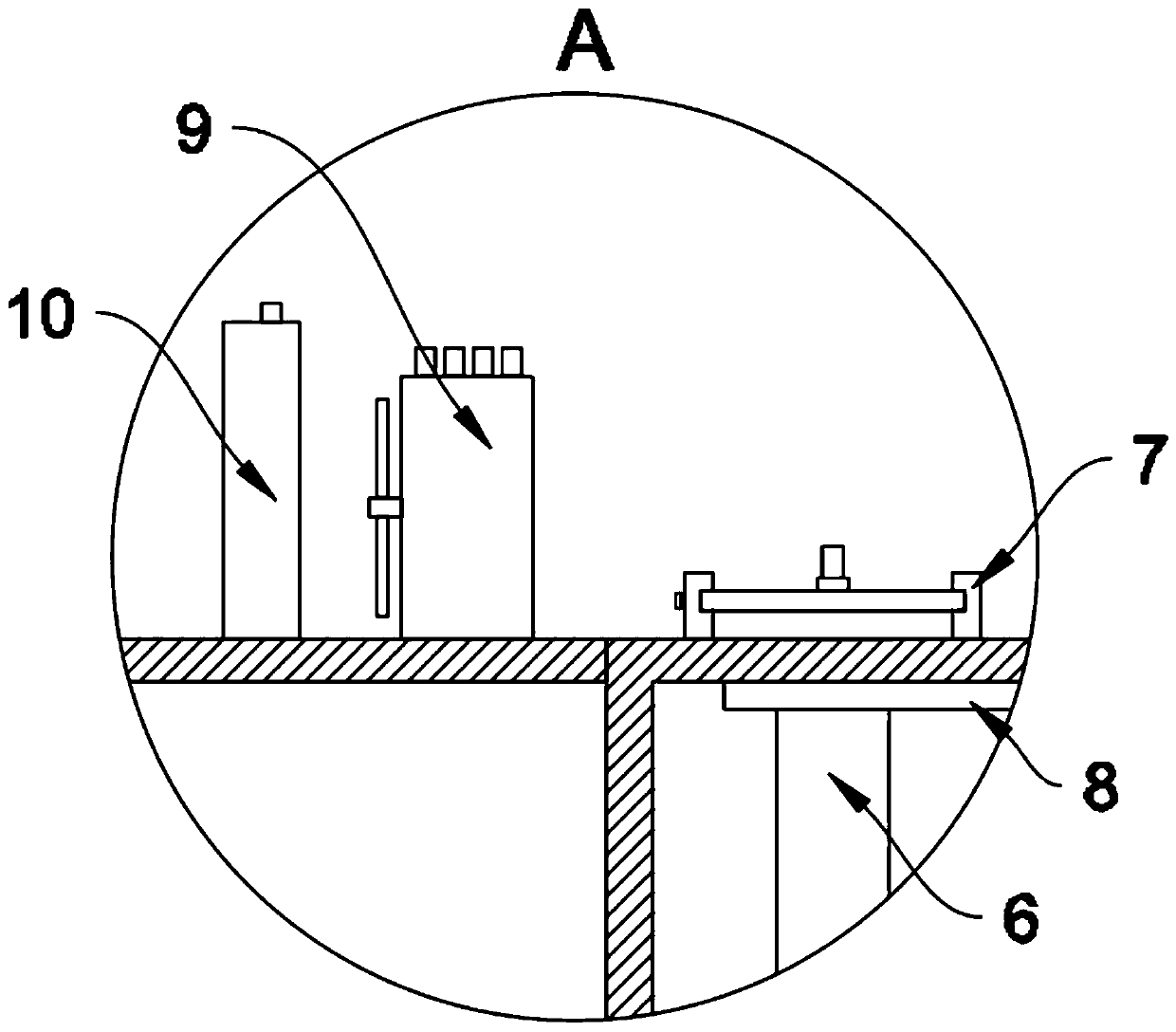

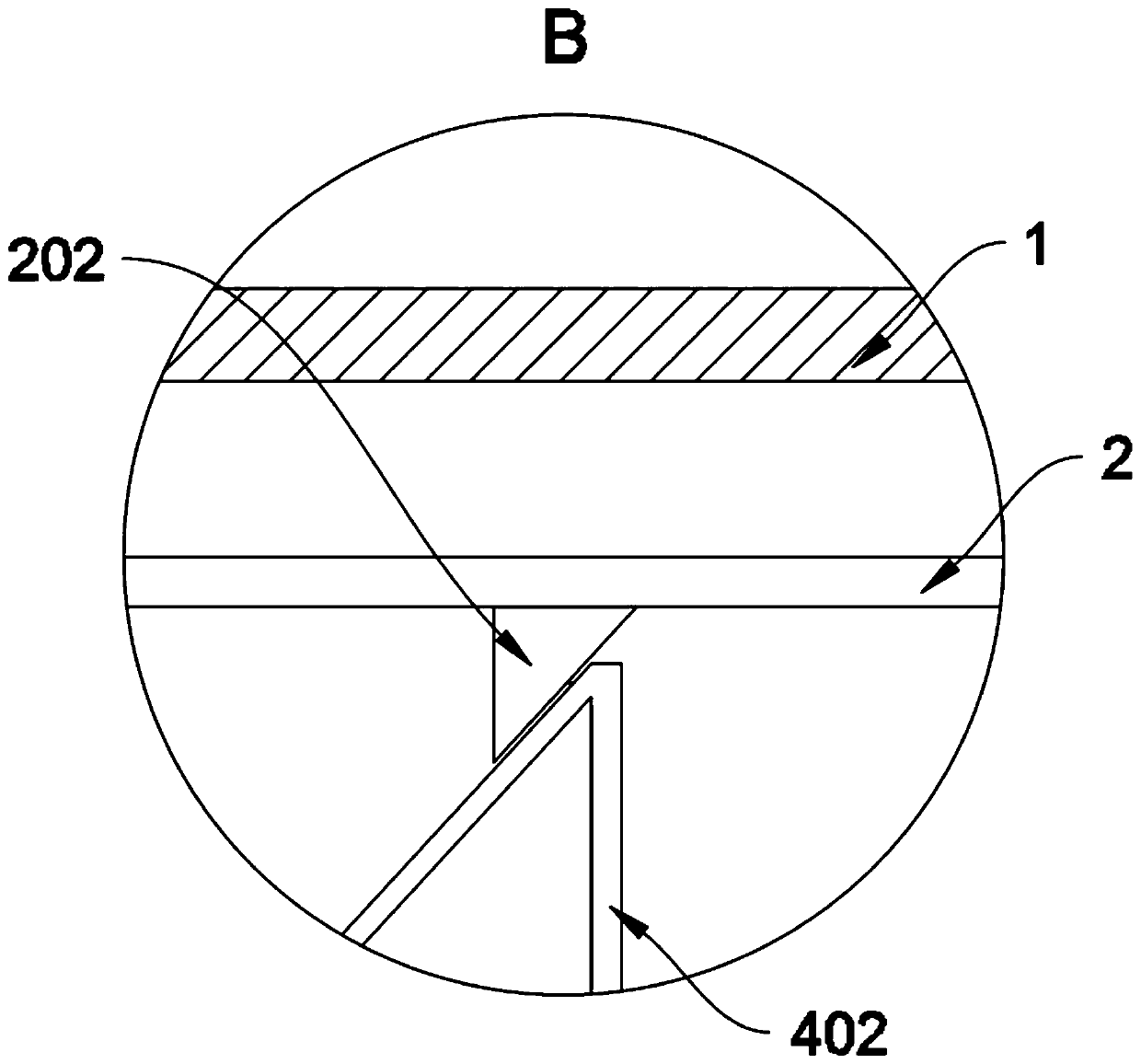

[0038] as attached figure 1 To attach Figure 8 Shown:

[0039] The invention provides an improved jet-suction flue gas cooling mixer for highway maintenance and repair, which includes a hot-melt kettle 1; a flow-guiding cylinder 2 is welded inside the hot-melt kettle 1, and a hot-melt kettle 1 is fixedly connected with a Fan 3; there is a jet-suction structure 4 on the fan 3 threaded connection; refer to as figure 1 image 3 with Figure 4The ejector-suction structure 4 includes a connecting pipe 401, an ejector-suction pipe and a throat 402, the right end of the connecting pipe 401 on the ejector-suction structure 4 is fixedly connected with the fan 3 through bolts, and the left end of the connecting pipe 401 is threadedly connected with an ejector-suction pipe and a throat 402; The suction pipe and the throat 402 are sealed and slidingly connected to the hot-melt kettle 1, and the throat in the suction pipe and the throat 402 has a frustum-like structure, so during use,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com