Automatic driving positioning control method for coke oven electric locomotive

A technology of automatic driving and positioning control, applied in coke ovens, furnace safety devices, petroleum industry, etc., can solve the problems of high labor intensity, large hidden dangers in operation, imperfect chain, etc., to reduce labor intensity and improve positioning accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

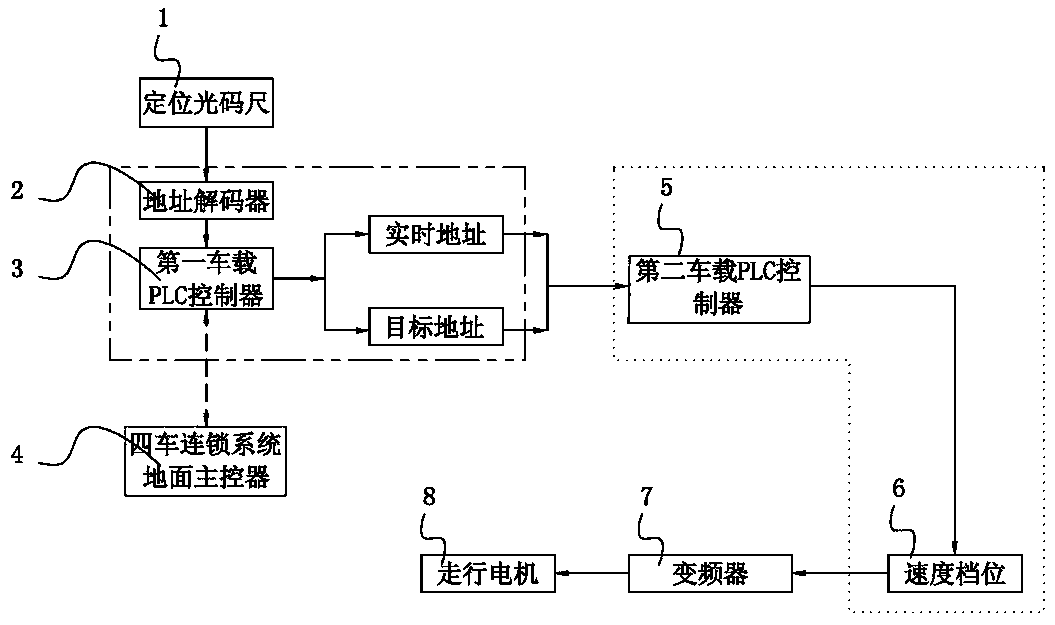

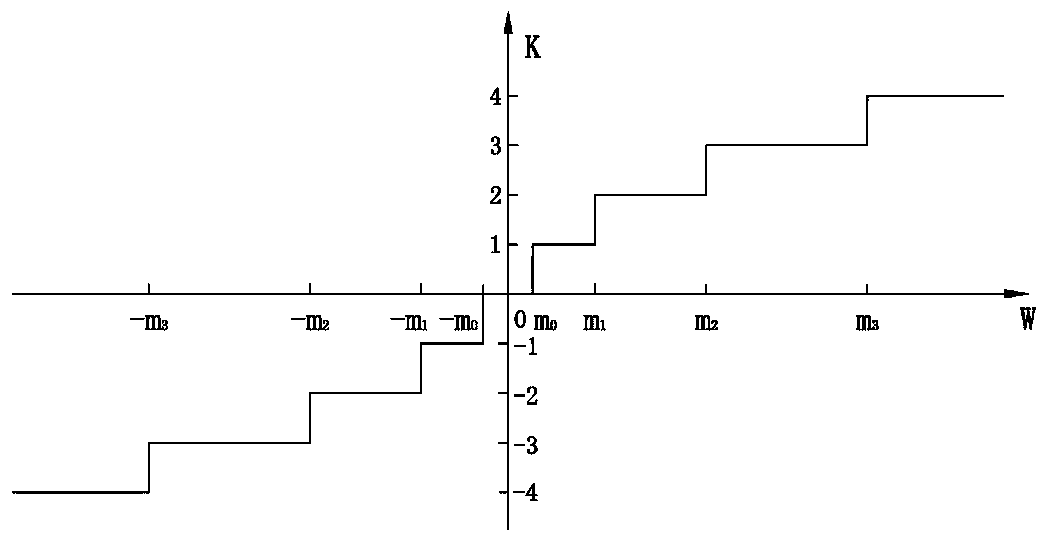

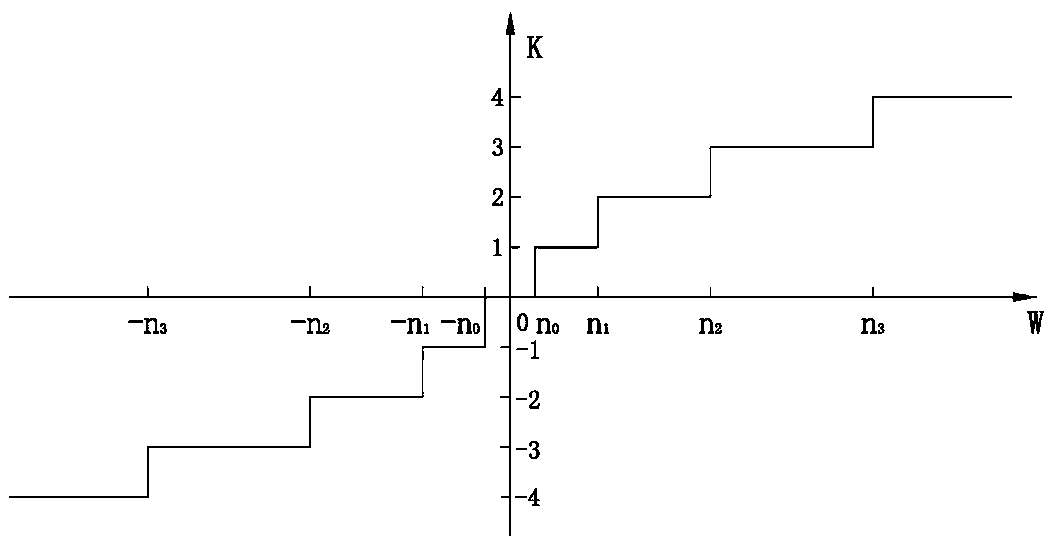

[0025] figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 with Image 6The shown coke oven electric locomotive automatic driving positioning control method is realized by using the coke oven electric locomotive automatic driving positioning control system. The system includes an address decoder 2 installed in the four-vehicle chain system. The real-time address data of the electric locomotive for positioning the optical code ruler 1 on the ground track, and transmit the real-time address data to the first vehicle-mounted PLC controller 3, and the first vehicle-mounted PLC controller 3 transmits the real-time address data and the set target address to the second vehicle-mounted PLC controller 5, and simultaneously transmitted to the ground master controller 4 of the four-vehicle interlocking system, the second vehicle-mounted PLC controller 5 co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com