A construction method for building large-scale aircraft workshop or hangar with thickened plastic clad aluminum composite board

A technology of aluminum composite panel and construction method, which is applied in the direction of building structure, building, building components, etc., can solve the problems of difficult technology, poor seismic performance, brittle and hard texture, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

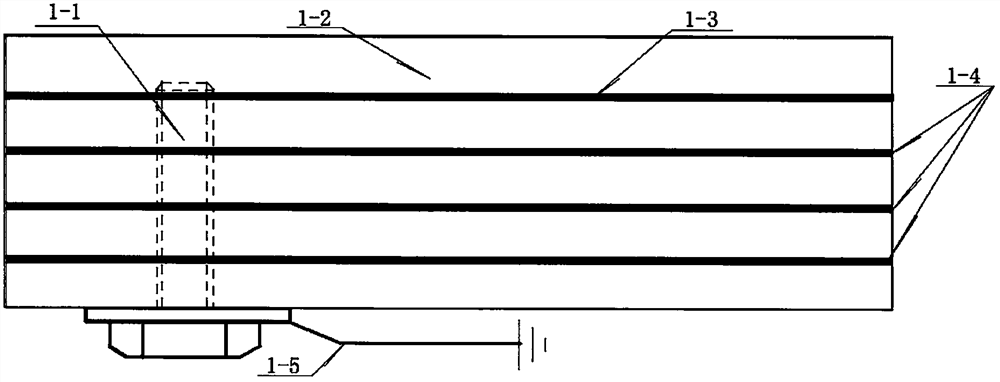

[0026] One. According to [0004], the manufacturing method of the thickened plastic sandwich aluminum composite panel selected by this patent is made by "multi-layer reinforcement semi-mechanized production equipment". Automate digital transformation.

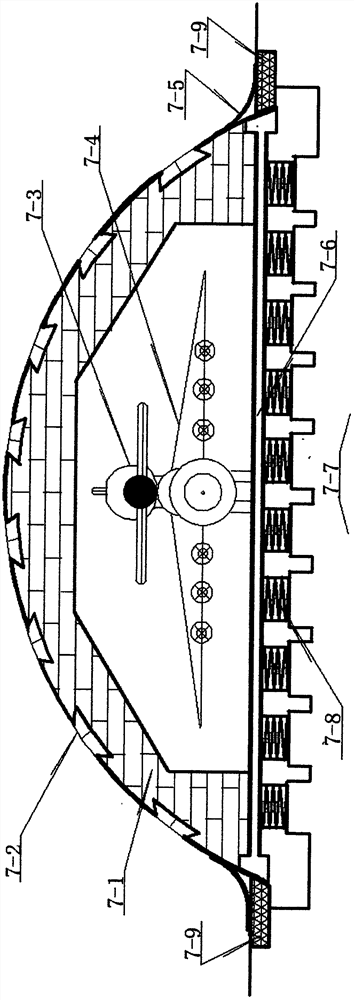

[0027] 2. According to [0009], in order to ensure that the design radian of the large hangar meets the standard and there is no distortion, when assembling, it is necessary to ensure that all parts are tightly jointed, the interface is straight and regular, and strict inspection standards and inspection procedures must be ensured.

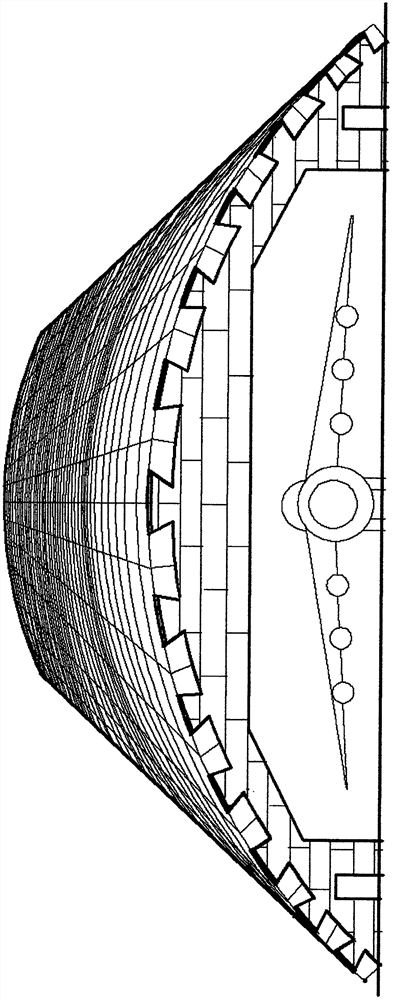

[0028] 3. According to [0010], the locking method is as follows: in tiles (such as Figure 4 4-1) Interface line (such as Figure 4 4-4) The vertical line AB of the upward lead intersects the interface line at K, and the point K is taken along the vertical line to both sides of the interface line according to 1 / 3 of the designed circular diameter to take O 1 , O 2 Two points, with the two points a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com