Nondestructive detection method for lithium separation of lithium ion battery and application method of detection method

A lithium-ion battery, non-destructive testing technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of low detection efficiency, long time, and long time for sealing, and achieve accurate test results and detection methods Simple and easy, the effect of simple and easy method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0045] The lithium-ion battery to be tested in this embodiment is a 2.15Ah-18650 lithium-ion battery after screening.

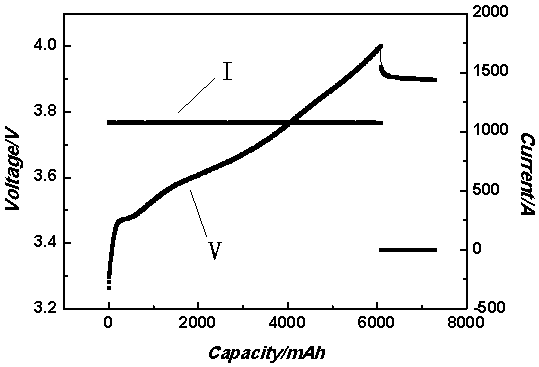

[0046] The use process of the lithium-ion battery to be tested can be simplified as the continuous repetition of charging, standing, and discharging. The relationship between voltage and time during use is shown in the attached figure 1 shown. The precipitation of metallic lithium occurs during battery charging during use. In this embodiment, the charging process of the lithium-ion battery to be tested is taken as the research object.

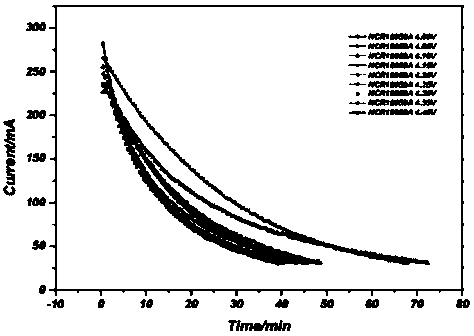

[0047] The relationship between the current and time during the constant voltage charging process of the lithium-ion battery to be tested is shown in the attached figure 2 shown. Constant voltage charging is a depolarization process. The internal polarization of the battery gradually decreases, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com