Efficient motion control system for electromotor fixed-frequency working condition and control method thereof

A motion control system and motor technology, applied in the direction of AC motor control, control system, electrical components, etc., can solve the problems that the zero point control unit cannot realize electrical and mechanical interlocking, signal interference, poor safety, etc., and achieve switching reliability and the effect of adjusting real-time problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

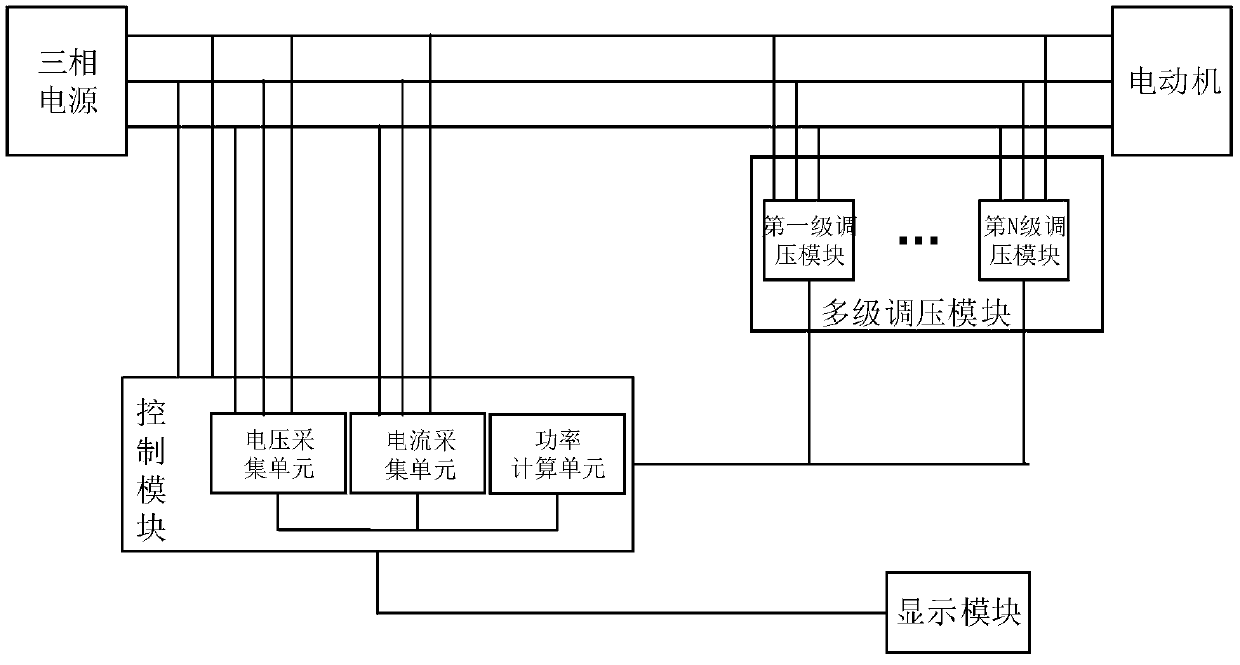

[0029] A high-efficiency motion control system for motors with constant frequency conditions, such as figure 1 As shown, it includes a three-phase power supply, a multi-stage voltage regulation module, a motor, a control module, a current protection module and a display module; the multi-stage voltage regulation module includes several voltage regulation modules with different control requirements, and the several voltage regulation modules are according to Cascade connection; the input end of the three-phase power supply is connected to the current protection module and the multi-stage voltage regulation module, the current protection module is connected to the power terminal VL of the control module, and the power terminal VN of the control module, and the multi-stage The voltage regulating module is connected to the control module, and the RS232-1 interface of the control module is connected to the display module;

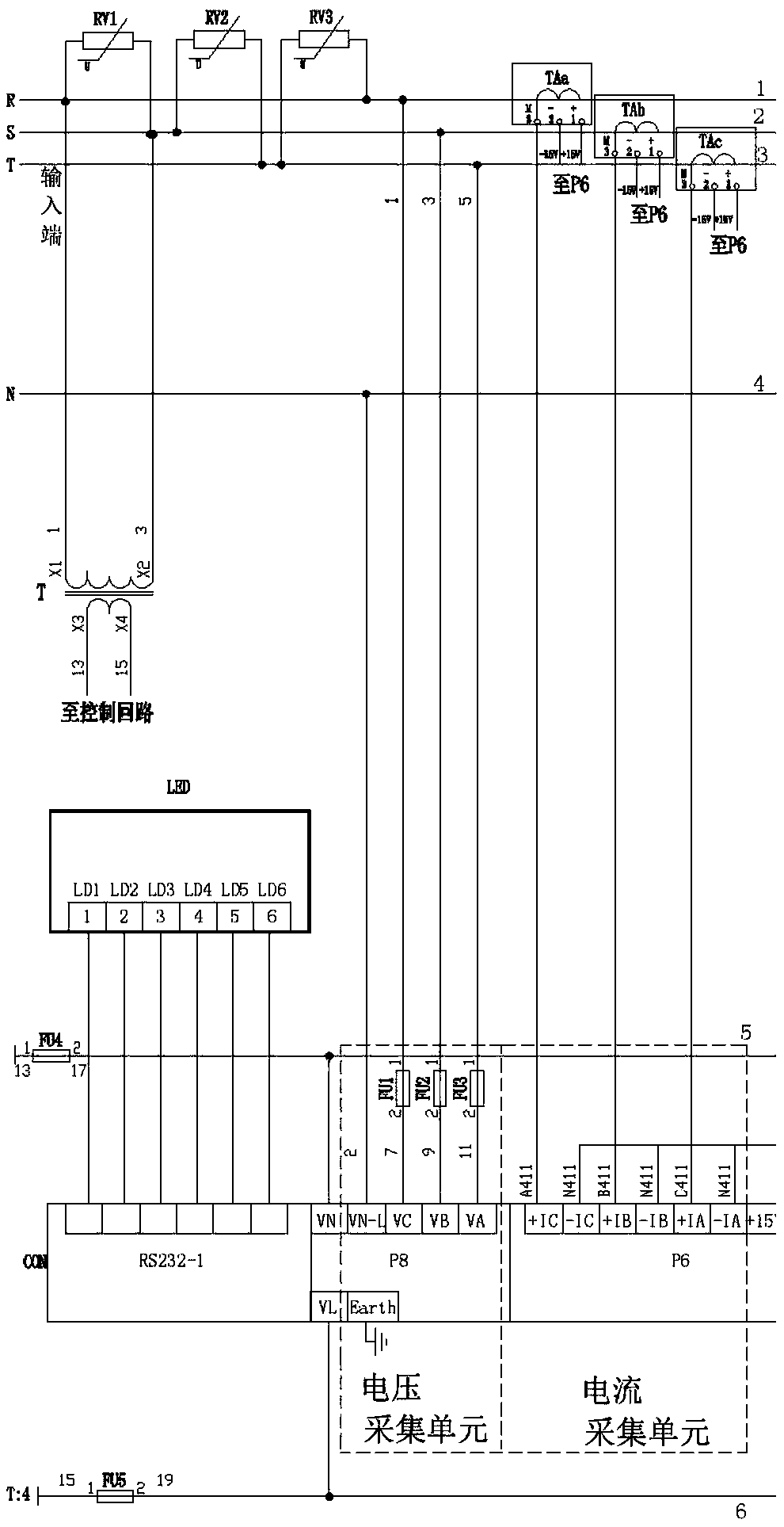

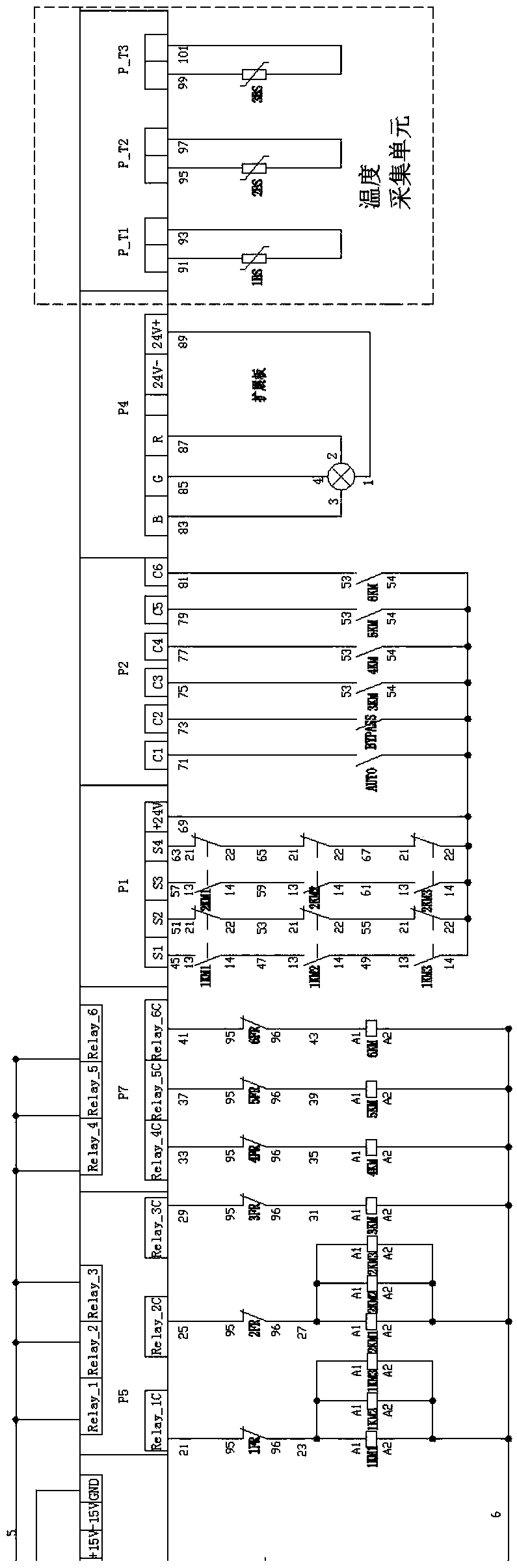

[0030] Such as figure 2 and image 3 As shown, the cont...

specific Embodiment approach 2

[0043] A control method realized by a high-efficiency motion control system based on the constant frequency working condition of the electric motor, comprising the following steps:

[0044] Step a, collecting the voltage value of the input terminal and the useful power value of the motor in real time;

[0045] Step b, calibrate the actual load capacity of the current motor according to the voltage value, set the load capacity of the motor system under the rated voltage to 1, and perform linear calibration if it exceeds or is lower than the value;

[0046] Step c, according to the actual load capacity and useful power value, through the motor optimal working curve algorithm, compare the actual measured load of the motor with the rated load, and calculate the optimal voltage parameter under the current measured load;

[0047] Step d, outputting the closest optimal voltage to control the motor through the multi-level voltage regulation module;

[0048] Step e, repeating steps a-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com