Method for chemically plating metal on copper substrate and printed circuit board and wafer prepared by same

A copper substrate and electroless plating technology, applied in the field of electroless metal plating, can solve the problems of unfriendly environment, influence of coating reliability, influence of bonding force between coating and base material, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

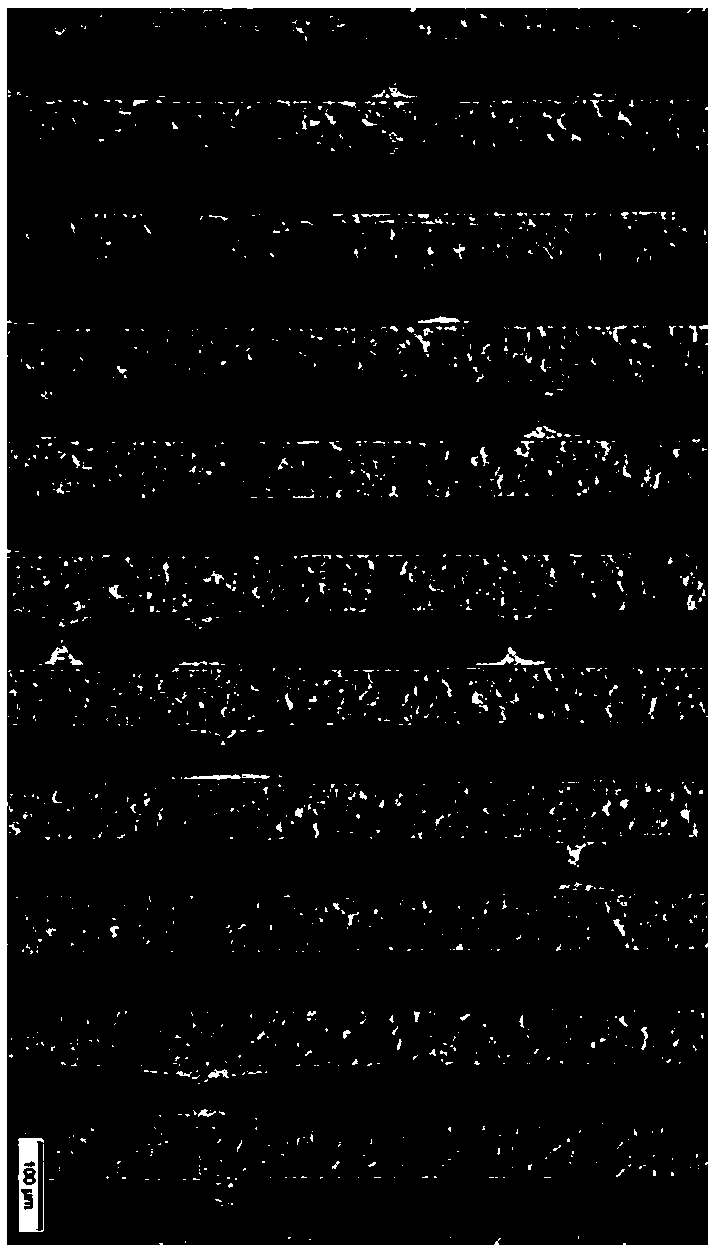

Embodiment 1

[0038] Embodiment 1 Immersion nickel gold on the printed circuit board

[0039] Process flow: degreasing→water washing→micro-etching→water washing→presoaking→activation→water washing→immersion nickel→water washing→immersion gold→water washing→drying

[0040] (1) Degreasing: Use TS-Acidclean 6189 degreasing agent from Guangdong Dongshuo Technology Co., Ltd., the operating temperature is 35°C, and the treatment time is 5 minutes.

[0041] (2) Microetching: The microetching agent is composed of 100 g / L sodium persulfate and 2% (v / v) sulfuric acid, the operating temperature is 30° C., and the treatment time is 2 minutes.

[0042] (3) Pre-soaking: 1% sulfuric acid is used for treatment, and a water bath jacket is installed outside the pre-soaking tank so that the temperature of the pre-soaking tank can be reduced to 20° C., and the treatment time is 2 minutes.

[0043] (4) Activation: use the TS-Activator LA activation solution produced by Guangdong Dongshuo Technology Co., Ltd., ...

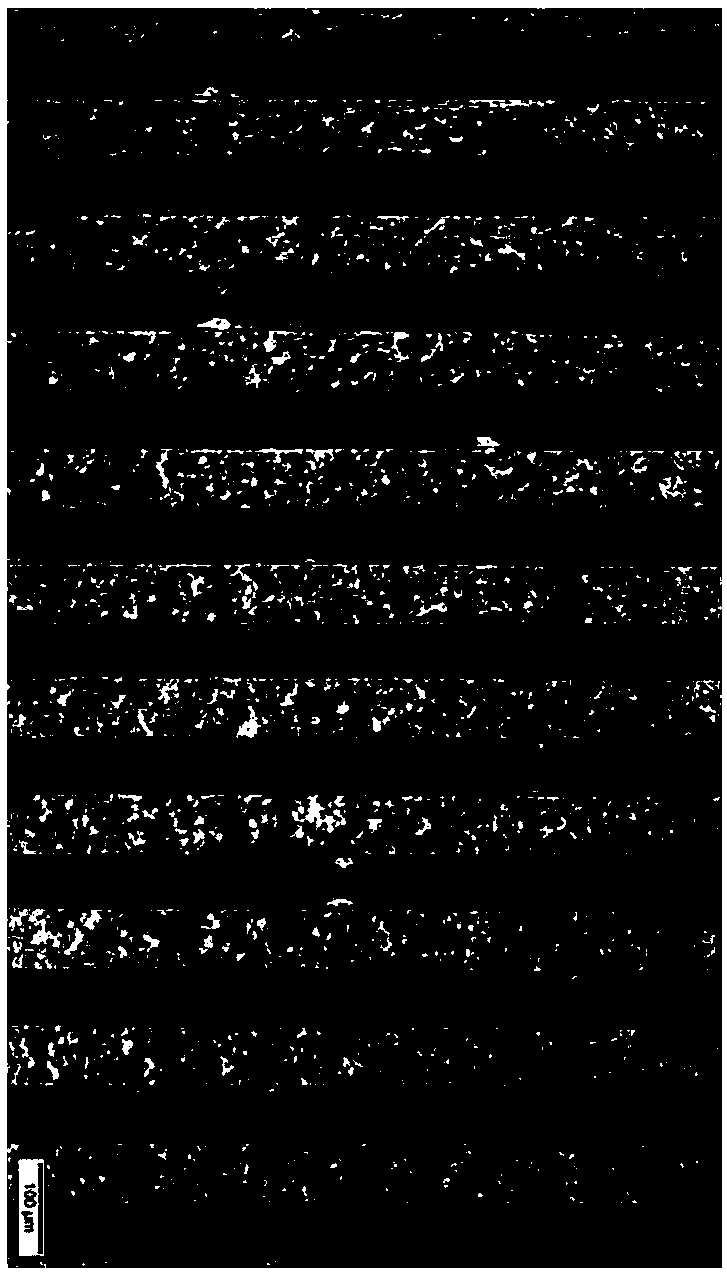

Embodiment 2

[0047] Embodiment 2 Immersion nickel gold on the printed circuit board

[0048] Process flow: degreasing→water washing→micro-etching→water washing→presoaking→activation→water washing→immersion nickel→water washing→immersion gold→water washing→drying

[0049] (1) Degreasing: Use TS-Acidclean 6189 degreasing agent from Guangdong Dongshuo Technology Co., Ltd., the operating temperature is 35°C, and the treatment time is 5 minutes.

[0050] (2) Microetching: The microetching agent is composed of 100 g / L sodium persulfate and 2% (v / v) sulfuric acid, the operating temperature is 30° C., and the treatment time is 2 minutes.

[0051] (3) Pre-soaking: 1% sulfuric acid is used for treatment, and a water bath jacket is installed outside the pre-soaking tank so that the temperature of the pre-soaking tank can be reduced to 15° C., and the treatment time is 2 minutes.

[0052] (4) Activation: use the TS-Activator LA activation solution produced by Guangdong Dongshuo Technology Co., Ltd., ...

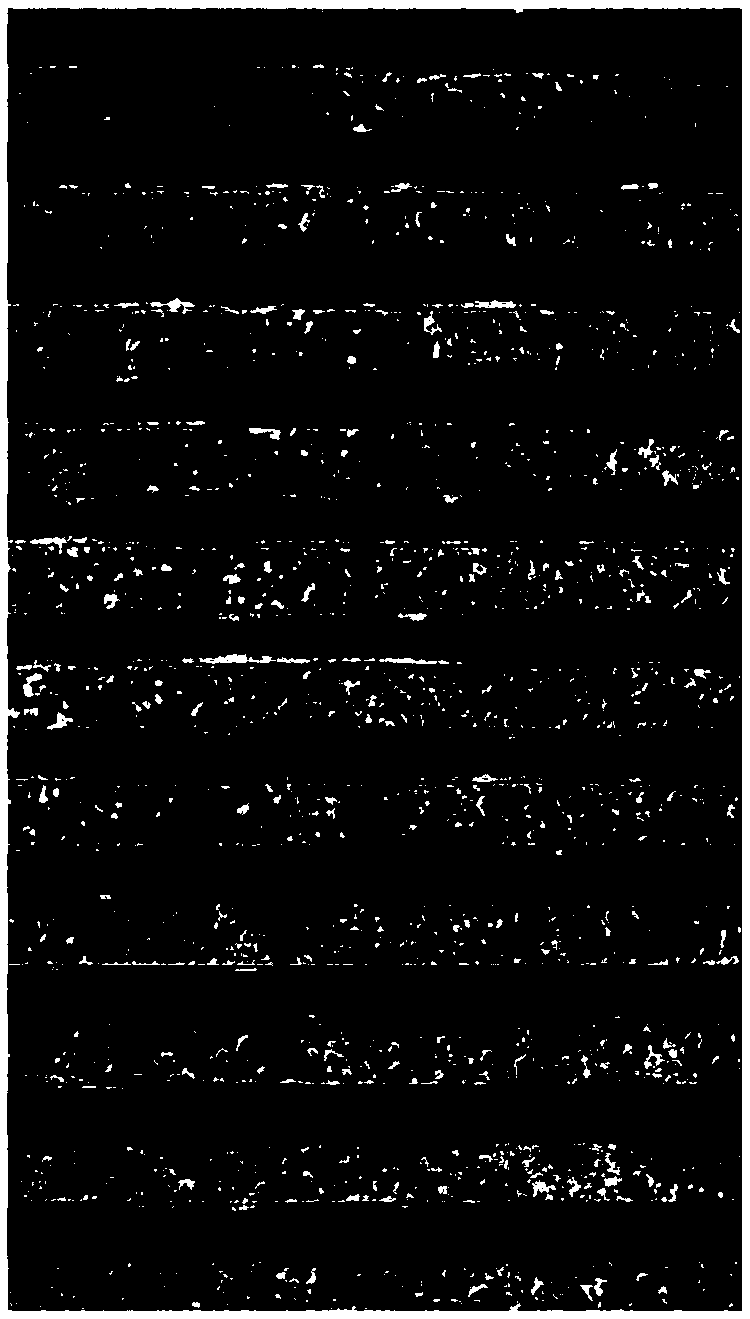

Embodiment 3

[0056] Embodiment 3 Immersion nickel gold on the printed circuit board

[0057] Process flow: degreasing→water washing→micro-etching→water washing→presoaking→activation→water washing→immersion nickel→water washing→immersion gold→water washing→drying

[0058] (1) Degreasing: Use TS-Acidclean 6189 degreasing agent from Guangdong Dongshuo Technology Co., Ltd., the operating temperature is 35°C, and the treatment time is 5 minutes.

[0059] (2) Microetching: The microetching agent is composed of 100 g / L sodium persulfate and 2% (v / v) sulfuric acid, the operating temperature is 30° C., and the treatment time is 2 minutes.

[0060] (3) Pre-soaking: 1% sulfuric acid is used for treatment, and a water bath jacket is installed outside the pre-soaking tank, so that the temperature of the pre-soaking tank can be reduced to 8° C., and the treatment time is 2 minutes.

[0061] (4) Activation: use the TS-Activator LA activation solution produced by Guangdong Dongshuo Technology Co., Ltd., ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com