Vertical water vapor and organic Rankine cycle parallel system driven by sintering waste heat

A Rankine cycle and water steam technology, which is applied in steam engine installations, steam generation methods using heat carriers, steam generation, etc., and can solve problems such as large flow rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

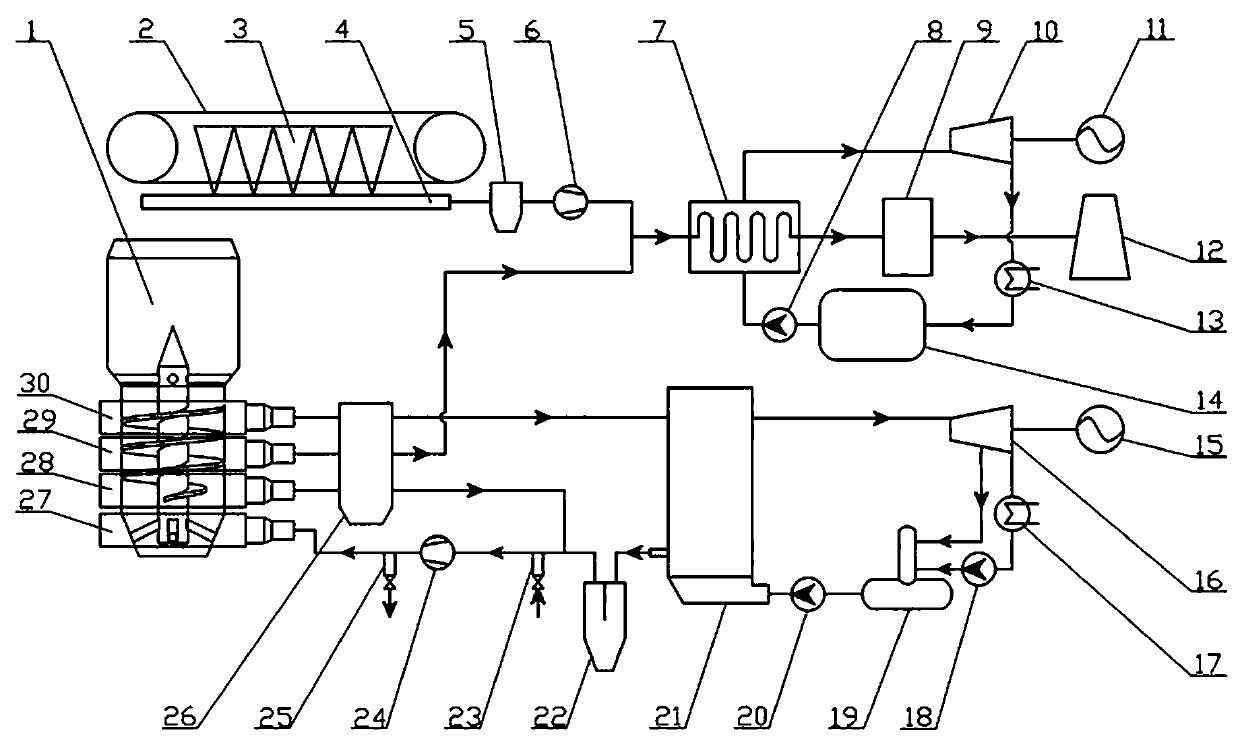

[0018] For a better understanding of the application, various aspects of the application will be described in more detail with reference to the accompanying drawings. It should be understood that these detailed descriptions are descriptions of exemplary embodiments of the application only, and are not intended to limit the scope of the application in any way. Throughout the specification, the same reference numerals refer to the same elements.

[0019] In the drawings, the thickness, size and shape of objects have been slightly exaggerated for convenience of illustration. The drawings are merely examples and are not strictly drawn to scale.

[0020] It should also be understood that the terms "comprising", "comprising", "having", "comprising", "comprising", when used in this specification, mean that there are described features, integers, steps, operations, elements and / or or components, but does not exclude the presence or addition of one or more other features, integers, s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap