Method of manufacturing semiconductor devices

A production method and semiconductor technology, applied in the fields of semiconductor devices, semiconductor/solid-state device manufacturing, electric solid-state devices, etc., can solve the problem of reducing the absolute accuracy of resistance value, preventing extensive miniaturization, and reducing the concentration and resistance value of resistance element diffusion layer. Small and other problems, to achieve the effect of easy control, high integration and remarkable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Several preferred embodiments of the present invention will now be described with reference to the accompanying drawings.

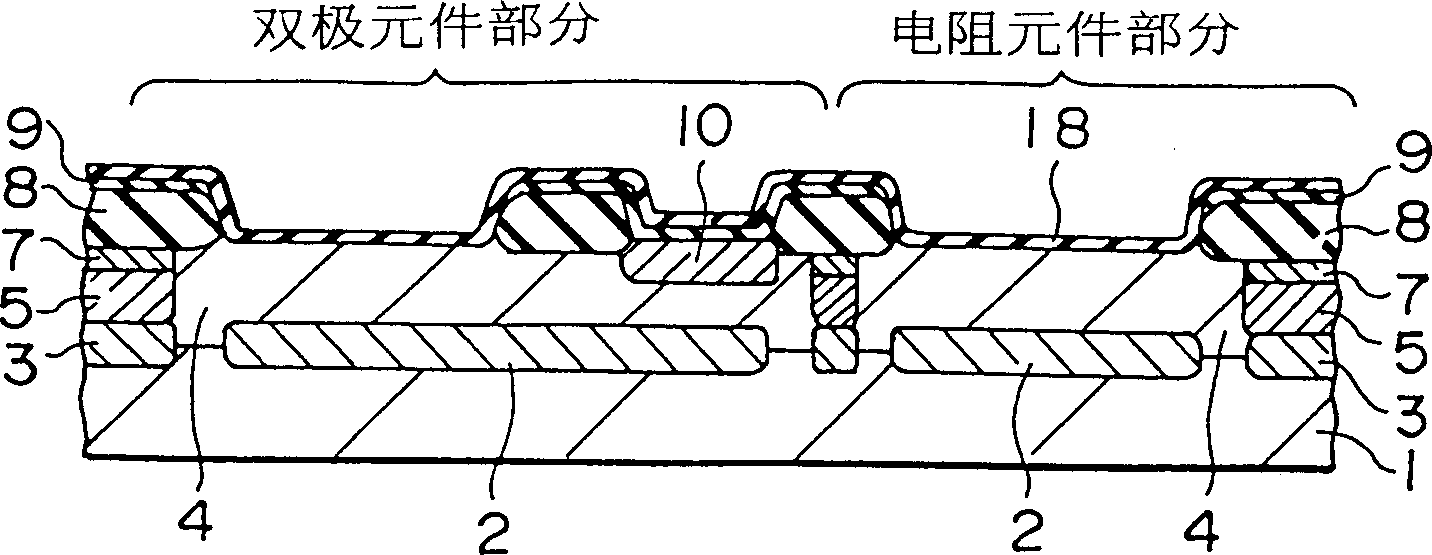

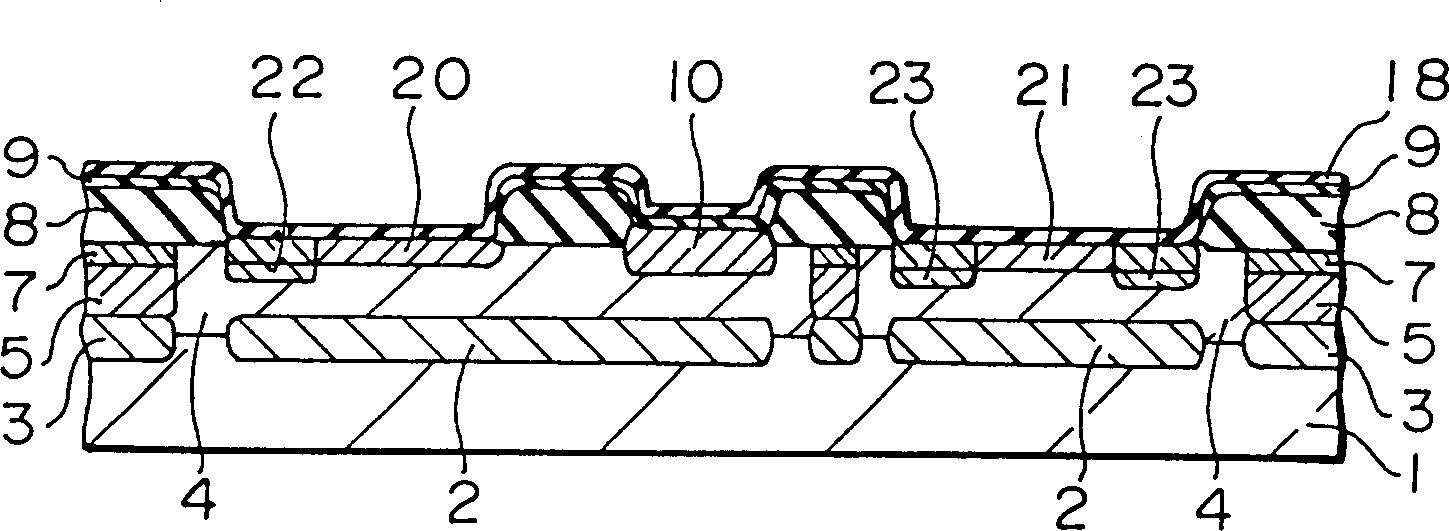

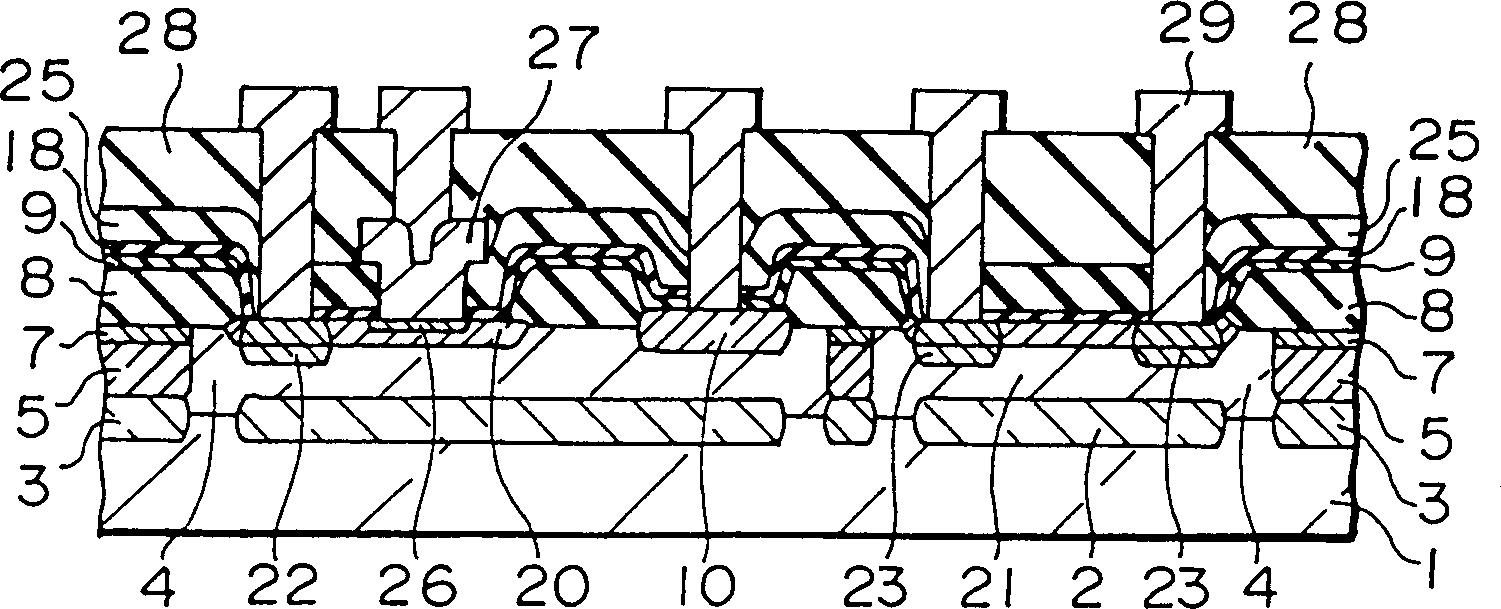

[0027] Figures 2A-2C is a sectional view sequentially showing the main constituent steps of the first preferred embodiment of the present invention. On the P-type silicon substrate 1, -N+ type embedded layer 2 and -P+ type embedded layer 3 are formed, followed by growing an N-type epitaxial layer 4 with a thickness of 1.0-3.0 microns, and -P-type well 5, A P-type channel stopper ring 7 and a field oxide film 8 are formed. Then, in an oxygen environment at a temperature of 900-1000° C., the total surface produced by oxidation is a thickness of 200 Å, forming the first oxide film 9, and passing through the partial collector region of the bipolar element at a thickness of about 1-2× 10 16 cm -2 Phosphorus is ion-implanted to form the -N+ type collector diffusion layer 10 . Up to the above step, the current method is the same as the conventional ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com