Anesthetic waste gas extracting device applied to anesthetic equipment

A technology for waste gas and equipment, applied in the field of medical devices, can solve the problems of inhalation, medical staff injury, lack of energy, etc., and achieve the effects of reasonable and simple structure, low production cost, and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

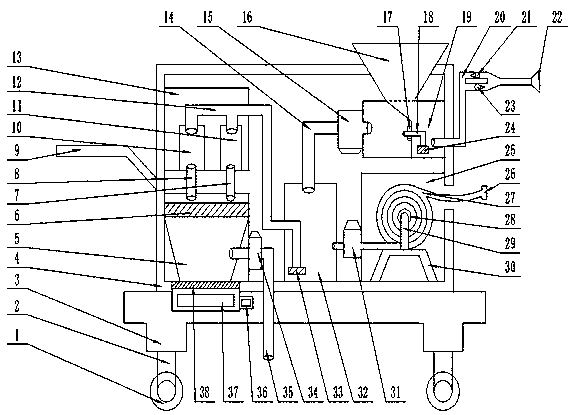

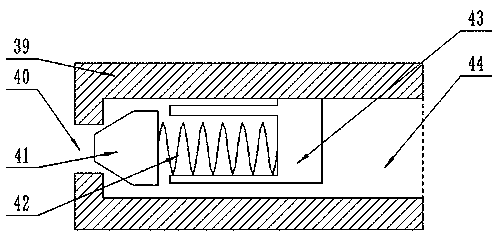

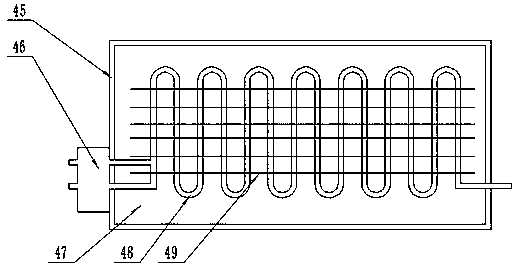

[0023] Such as Figure 1 to Figure 3As shown, this specific embodiment adopts the following technical solutions: an anesthesia waste gas extraction device for anesthesia equipment, including a universal wheel 1, a universal wheel support rod 2, a device base 3, a device shell 4, an evaporation chamber 5, a first Filter screen 6, first pipeline 7, second pipeline 8, handrail 9, solution tank 10, solution cylinder 11, third pipeline 12, filter chamber 13, fourth pipeline 14, first air pump 15, anesthetic agent inlet 16, atomization Device 17, atomizer tube 18, anesthetic agent cartridge 19, fourth pipeline 20, first one-way air valve 21, disposable suction nozzle 22, second one-way air valve 23, first filter tip 24, hose storage chamber 25. Universal joint 26, extended hose 27, disk 28, disk support rod 29, disk support 30, second air pump 31, gas mixing chamber 32, second filter 33, evaporator 34, fifth pipeline 35 , an electric heater 36, a heating layer 37 and a second filte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com