Heat pump driven benzene tower fractionation device and method

A heat pump-driven, fractional distillation device technology, applied in the field of aromatic hydrocarbon separation, can solve the problems of affecting the colorimetric index of benzene and benzene products in acid washing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

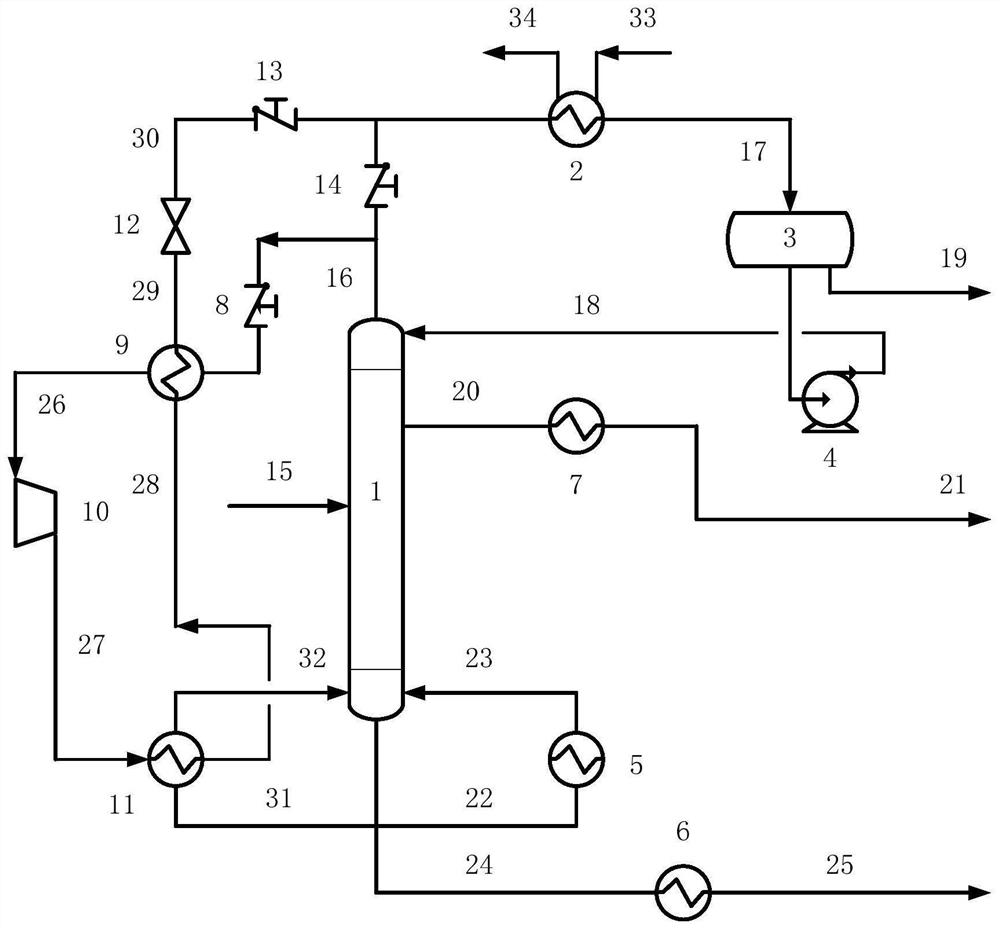

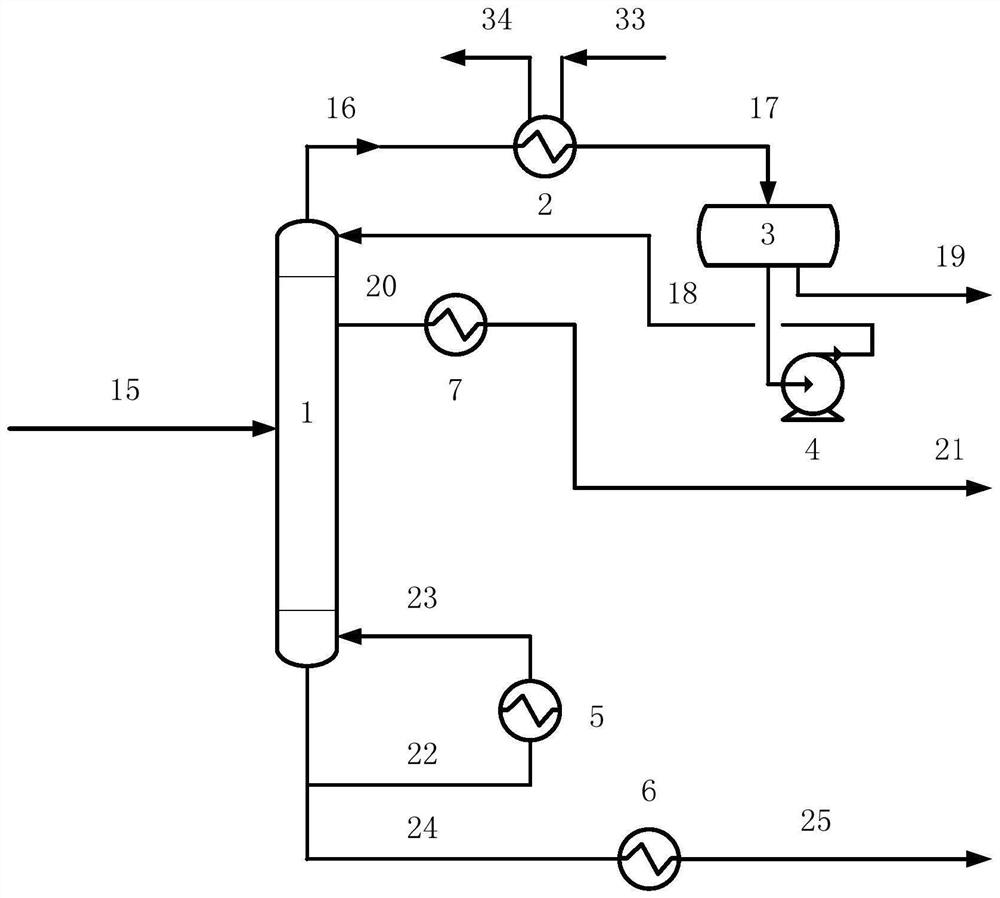

[0025] Preferred embodiments of the present invention will be described in more detail below with reference to the accompanying drawings. Although preferred embodiments of the invention are shown in the drawings, it should be understood that the invention may be embodied in various forms and should not be limited to the embodiments set forth herein.

[0026] refer to figure 1 , the benzene tower fractionation device driven by heat pump according to the present invention comprises: benzene tower 1; compression preheater 9, communicated with the top of the benzene tower through the first shut-off valve; compressor 10, communicated with compression preheater 9; heat pump reboiler 11, connected to the compressor 10 and the compression preheater 9, and connected to the bottom of the benzene tower; the pressure relief valve 12, connected to the compression preheater 9; the waste heat recovery heat exchanger 2 at the top of the tower, connected to the pressure relief valve 12 through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com