Method for controlling and preparing vaterite calcium carbonate by using sinapic acid

A technology of sinapinic acid and calcium carbonate, which is applied in the fields of calcium carbonate/strontium/barium, chemical instruments and methods, calcium/strontium/barium compounds, etc. It can solve problems such as difficult control of reaction conditions, high cost of organic matter sources, and complicated preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

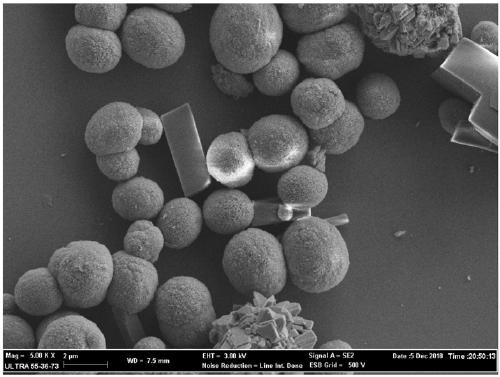

Image

Examples

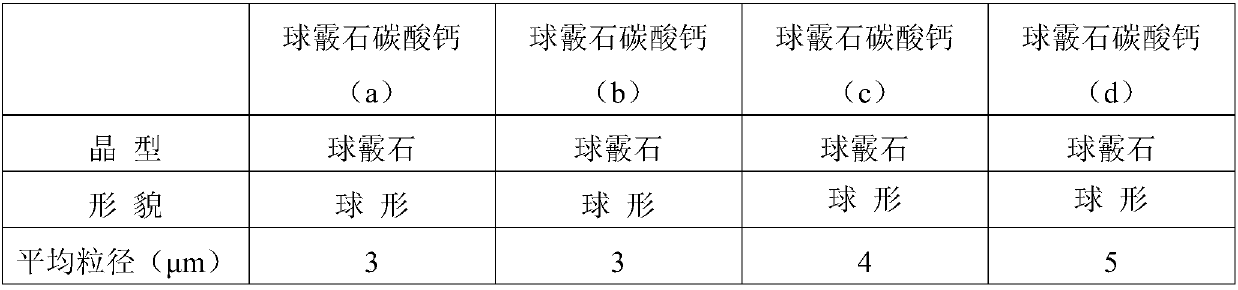

Embodiment 1

[0020] 1) In a water bath with magnetic stirring, dissolve sinapinic acid in deionized water and stir for 10 minutes to form a 10g / L sinapinic acid solution;

[0021] 2) In a water bath with magnetic stirring, add 1.4 g of anhydrous CaCl to 12.5 mL of the sinapinic acid solution obtained in step 1) 2 , stirred for 10min to form sinapinic acid-CaCl 2 compound solution;

[0022] 3) Use 1mol / L NaOH solution to adjust step 2) to obtain sinapinic acid-CaCl 2 Composite solution makes its pH=7;

[0023] 4) In a water bath with magnetic stirring, 12.5 mL of 0.2 mol / L Na 2 CO 3 The solution was added to the pH 7 sinapinic acid-CaCl obtained in step 3) 2 In the composite solution, after stirring for 10 minutes, seal at 25°C and crystallize at a constant temperature for 24 hours to obtain a solution containing precipitation;

[0024] 5) Wash the precipitation-containing solution obtained in step 4) with deionized water and absolute ethanol for 3 times respectively, centrifuge at 78...

Embodiment 2

[0026] 1) In a water bath with magnetic stirring, dissolve sinapinic acid in deionized water and stir for 10 minutes to form a 20g / L sinapinic acid solution;

[0027] 2) In a water bath with magnetic stirring, add 2.1 g of anhydrous CaCl to 12.5 mL of the sinapinic acid solution obtained in step 1) 2 , stirred for 10min to form sinapinic acid-CaCl 2 compound solution;

[0028] 3) Use 1mol / L NaOH solution to adjust step 2) to obtain sinapinic acid-CaCl 2 Composite solution makes its pH=9;

[0029] 4) In a water bath with magnetic stirring, 12.5 mL of 0.3 mol / L Na 2 CO 3 Add the solution to the pH 9 sinapinic acid-CaCl obtained in step 3) 2 In the composite solution, after stirring for 10 minutes, seal at 40°C and crystallize at a constant temperature for 18 hours to obtain a solution containing precipitation;

[0030] 5) Wash the precipitation-containing solution obtained in step 4) with deionized water and absolute ethanol for 3 times respectively, centrifuge at 7830r / mi...

Embodiment 3

[0032] 1) In a water bath with magnetic stirring, dissolve sinapinic acid in deionized water and stir for 10 minutes to form a 30g / L sinapinic acid solution;

[0033] 2) In a water bath with magnetic stirring, add 2.8 g of anhydrous CaCl to 12.5 mL of the sinapinic acid solution obtained in step 1) 2 , stirred for 10min to form sinapinic acid-CaCl 2 compound solution;

[0034] 3) Use 1mol / L NaOH solution to adjust step 2) to obtain sinapinic acid-CaCl 2 Composite solution makes its pH=10;

[0035] 4) In a water bath with magnetic stirring, 12.5 mL of 0.4 mol / L Na 2 CO 3 The solution was added to the pH 10 sinapinic acid-CaCl obtained in step 3) 2 In the composite solution, after stirring for 10 minutes, seal at 45°C and crystallize at a constant temperature for 12 hours to obtain a solution containing precipitation;

[0036]5) Wash the precipitation-containing solution obtained in step 4) with deionized water and absolute ethanol for 3 times respectively, centrifuge at 7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com