Optical fiber connector and assembly method thereof

A technology of optical fiber connector and optical fiber, which is applied in the coupling direction of optical waveguide, etc., can solve the problems of short length of stress buffer boot, easy damage of optical cable, complex structure, etc., and achieve the effect of simplifying structure, reducing quantity and small total length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

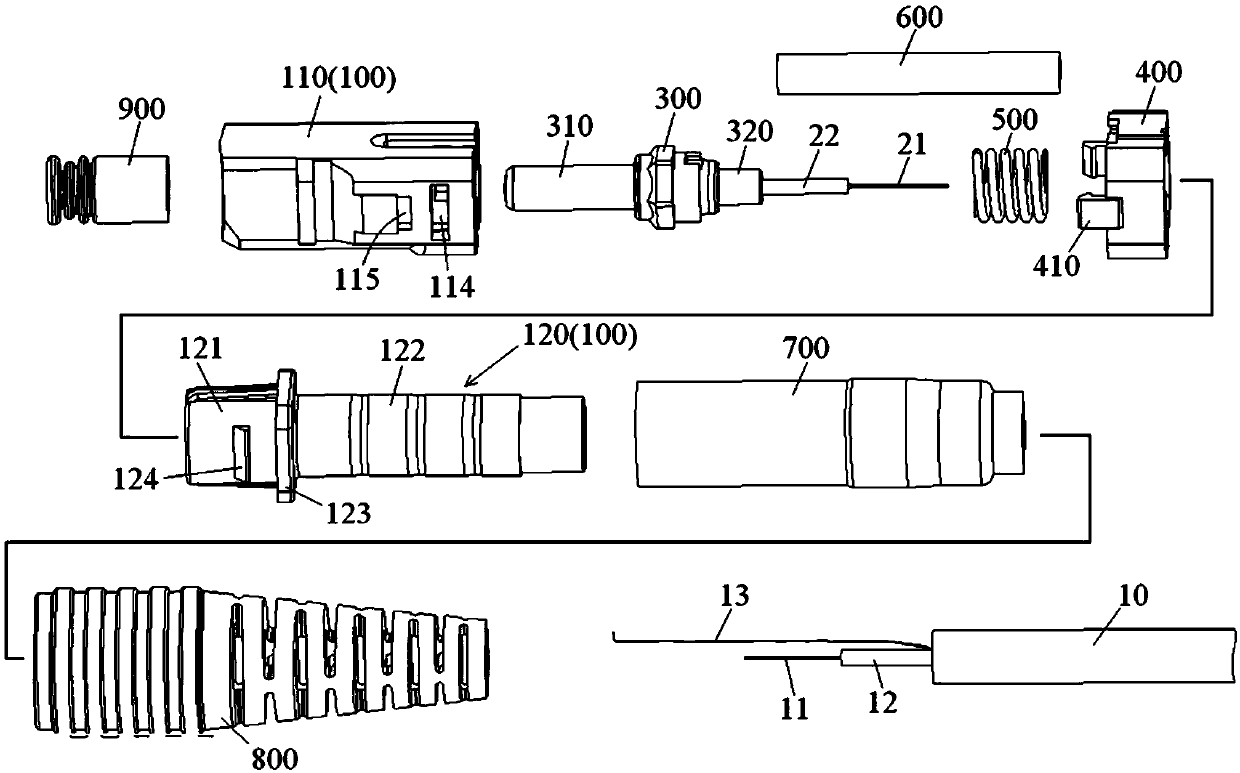

[0073] figure 1 An exploded view of the optical fiber connector according to the first exemplary embodiment of the present invention is shown, wherein the outer housing 200 is not shown.

[0074] Such as figure 1 As shown, in an exemplary embodiment of the present invention, an optical fiber connector mainly includes an inner housing 100 , an outer housing 200 , a ferrule assembly, a spring 500 , a heat shrinkable tube 700 and a stress buffer shoe 800 .

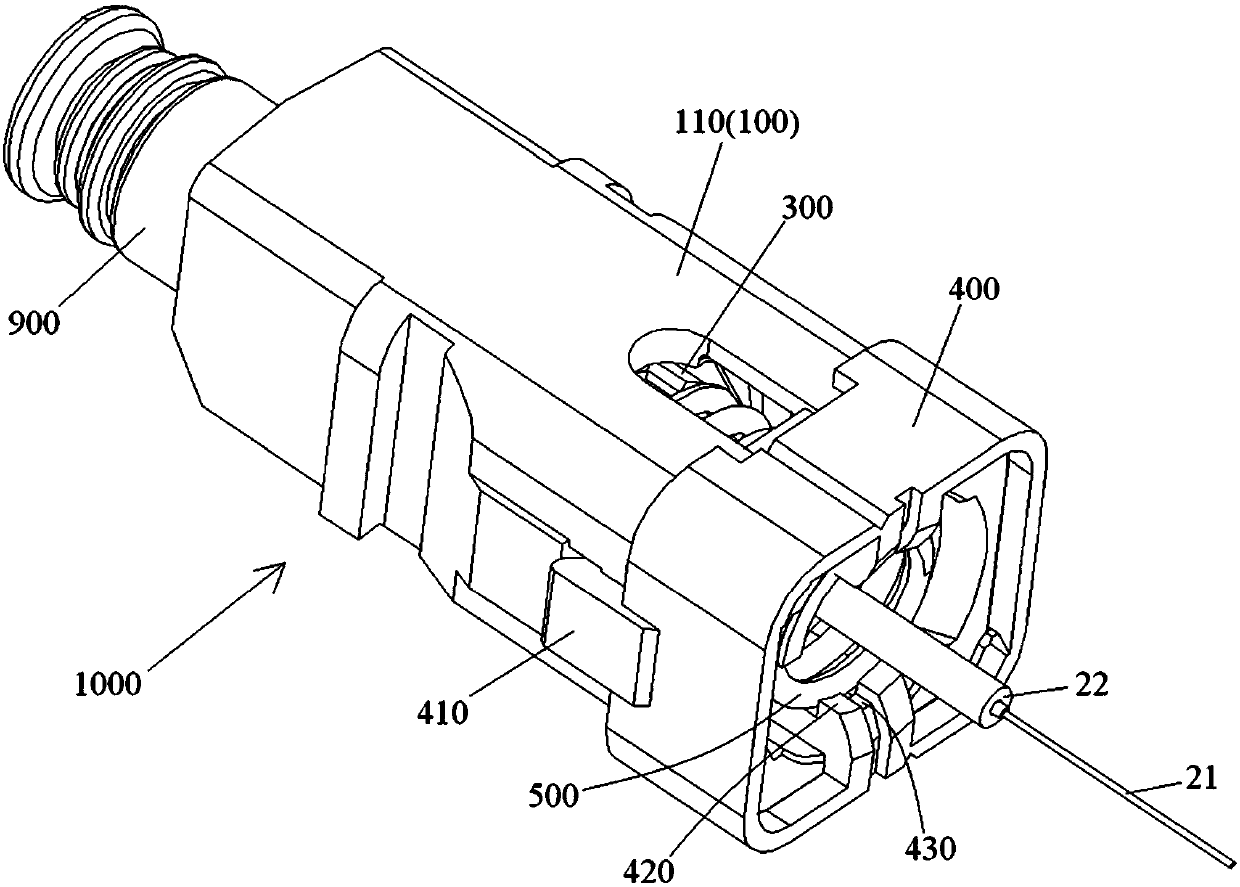

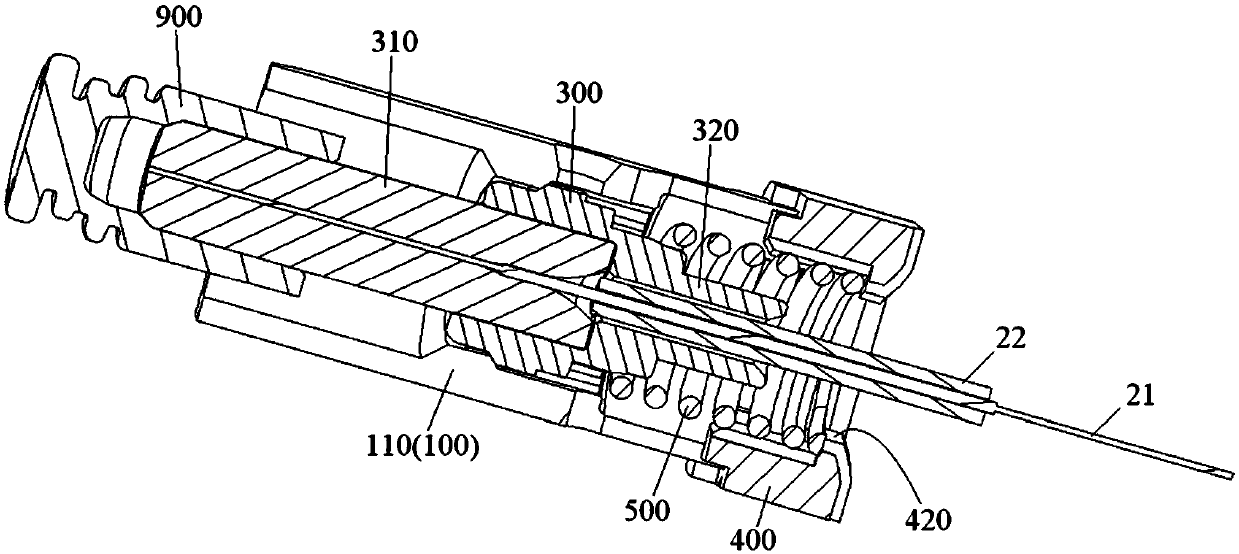

[0075] Figure 10 A schematic diagram showing a complete optical fiber connector formed after fitting the stress buffer boot 800 onto the heat shrink tube 700 and the optical cable 10 and installing the inner housing 100 into the outer housing 200; Figure 11 show Figure 10 Cutaway view of the fiber optic connector shown.

[0076] Such as figure 1 , Figure 10 with Figure 11 As shown, in the illustrated embodiment, the ferrule assembly is housed in the inner housing 100 , and the ferrule assembly includes a ferrule 3...

no. 2 example

[0110] Figure 12 shows a cross-sectional view of an optical fiber connector according to a second exemplary embodiment of the present invention, wherein the outer housing is not shown; and Figure 13 show Figure 12 A cutaway view of the fiber optic connector is shown, where the outer housing and fiber optic cable are not shown.

[0111] Figure 12 with Figure 13 Shown is a second embodiment of the fiber optic connector with Figure 1 to Figure 11 The main difference of the optical fiber connector of the first embodiment shown is the fixing structure of the Kevlar fiber used to fix the optical cable. besides, Figure 12 with Figure 13 Shown is a second embodiment of the fiber optic connector with Figure 1 to Figure 11 The optical fiber connectors in the first embodiment shown are basically the same, and for the sake of brevity, only the differences between the first embodiment and the second embodiment will be described below.

[0112] Such as Figure 12 with Fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com