Rapid anaerobic fermentation system

An anaerobic fermentation and rapid technology, applied in the field of biogas, can solve the problems of easy crusting of fermentation tanks, waste of time in fermentation time, crop damage, etc., and achieve the effects of wide application range, improvement of fermentation degree, and improvement of fermentation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

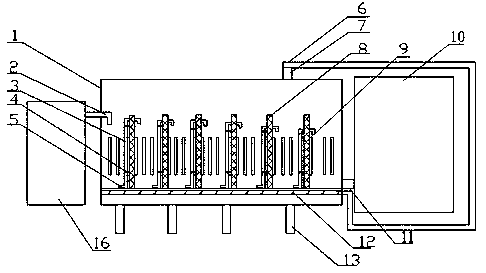

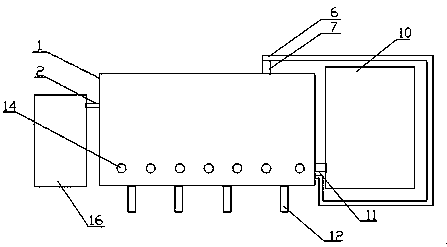

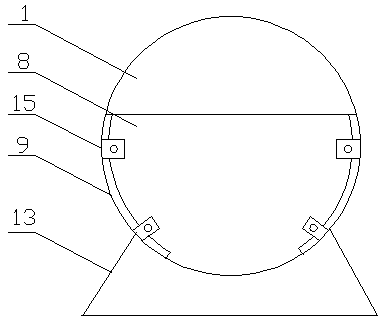

[0034] Such as figure 1 --A fast anaerobic fermentation system shown in 3, comprising: wet and dry separator 16, horizontal fermenter 1 and soft liquid storage tank 10, wherein: the two ends of the horizontal fermenter 1 are respectively provided with sewage Inlet 2 and liquid outlet 11, the rice end of the sewage inlet goes deep below the biogas liquid level to prevent biogas from overflowing, the dry-wet separator 16 is connected to the sewage inlet 2, and the liquid outlet is connected to the soft liquid storage pool 10, The interior of the horizontal fermenter 1 is divided into multiple chambers through a plurality of partitions 8 whose height is lower than that of the horizontal fermenter 1, but the upper part of the fermenter is still a cavity, and each partition 8 is passed through the first A fixing piece 4 fixes the biogas slurry pipe 3, and the biogas slurry pipe 3 extends from the bottom end of the partition plate 8 to the top and penetrates into the adjacent chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com