Gas well ultrasonic levitation, liquid discharge and gas production system and implementation method

A technology for liquid-draining gas production and gas wells, which is applied in the fields of fluid production, earth-moving drilling, wellbore/well components, etc. It can solve the problems of easy gas lock, incomplete natural gas production, serious environmental pollution, etc., and reduce bottom-hole flow. pressure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing:

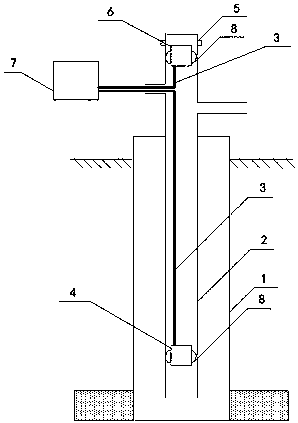

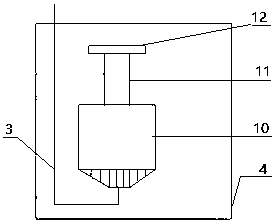

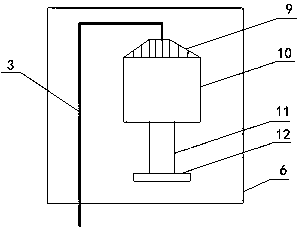

[0012] Such as figure 1 As shown, the wellhead acoustic wave emitter 6 is installed below the wellhead blowout preventer 5, and the wellhead acoustic wave emitting device 6 is installed downhole; the downhole acoustic wave emitter 4 and the wellhead acoustic wave emitting device 6 are fixed on the oil pipe 2 through the righting and locking device 8 and are erected. In the horizontal center of the wellbore; the downhole acoustic wave transmitter 4 and the wellhead acoustic wave transmitting device 6 realize the connection between the acoustic wave transmitter and the ground controller 7 through the cable 3 to form a working system; figure 2 , 3 As shown, the sound wave transmitter is composed of a power supply module 9, a transducer 10, a horn 11 and a sound wave transmitting end 12; the power module 9 of the downhole sound wave launcher 4 and the wellhead sound wave emis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com