Humidification device for aquatic feed making machine through atomization, diversion, rotation and dispersion

A humidification device and aquaculture feed technology, applied in feed, food science, application and other directions, can solve the problems of mildew, low utilization rate of wet airflow, affecting work efficiency, etc., and achieve the effect of preventing mildew

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

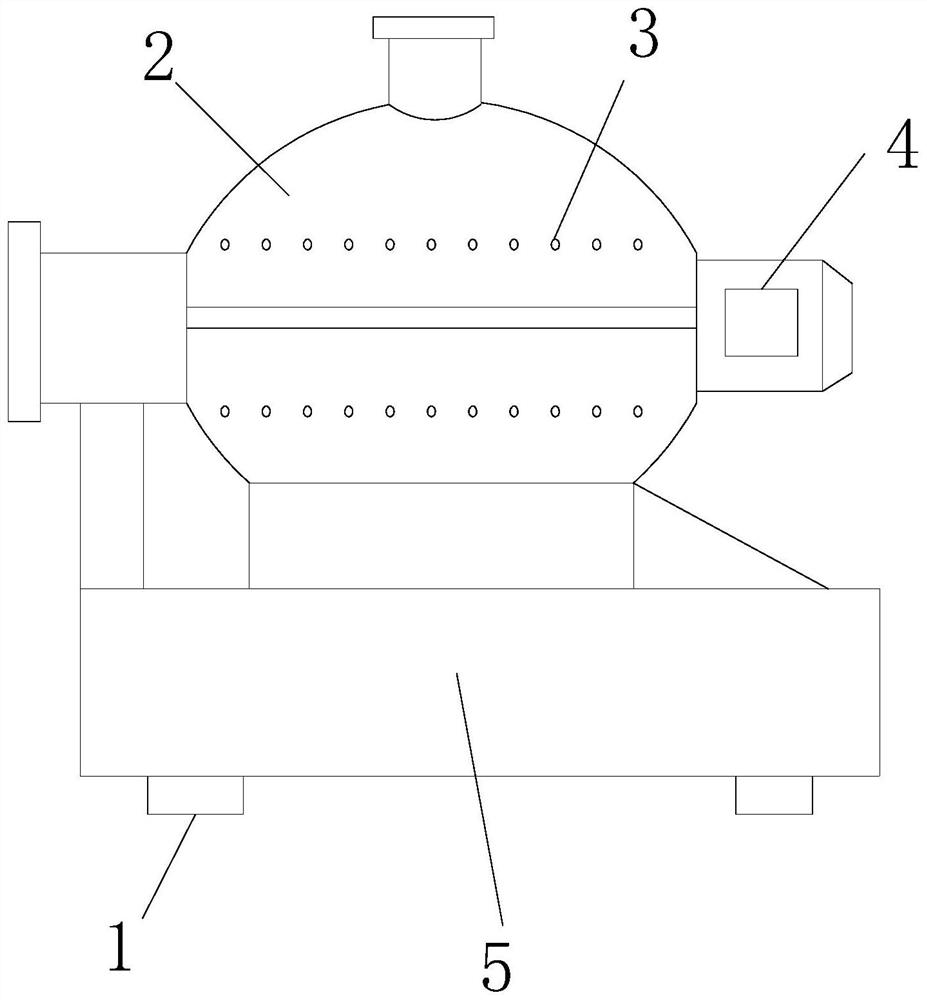

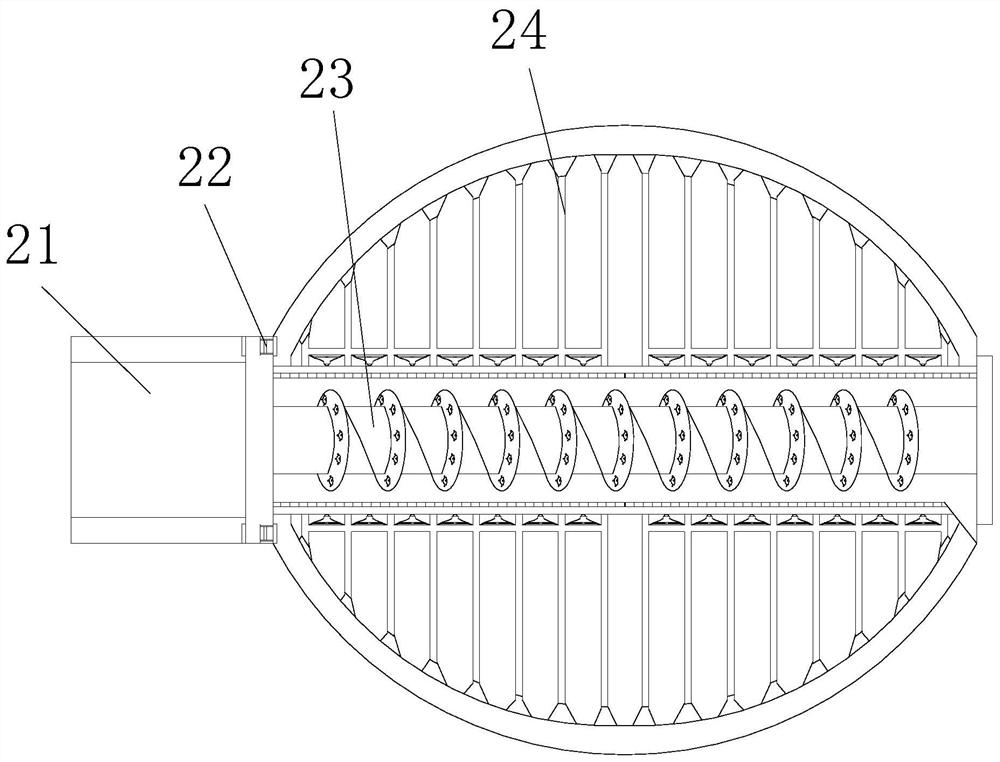

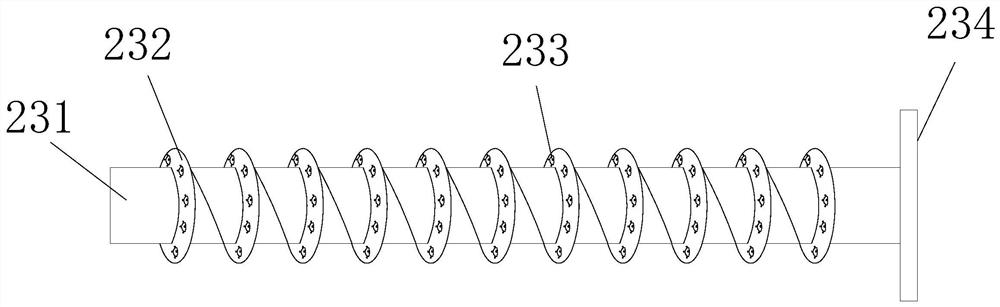

[0027] see figure 1 , the present invention provides a humidifying device for an aquatic feed making machine through atomization, diversion, rotation, and dispersion. The structure includes: a support pad 1, an intelligent humidifying device 2, a water outlet 3, a power motor 4, and a fixed base 5. The right end surface of the intelligent humidifying device 2 is fixedly connected with the intelligent humidifying device 2, the water outlet hole 3 is set on the outer end surface of the intelligent humidifying device 2 and is fixedly connected with the intelligent humidifying device 2 at the same time, and the fixed base 5 is located at the intelligent humidifying device 2 and is fixedly connected with the intelligent humidifying device 2, the support pad 1 is set on the lower surface of the fixed base 5 and is fixedly connected with the fixed base 5, the water outlet hole 3 is connected with the external water collecting device, through The connected water collection device can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com