Crushing box special for waste recovery device for environment-friendly construction

A recovery device and crushing box technology, which is applied in solid separation, chemical instruments and methods, grain processing, etc., can solve the problems of hardening, large lumps, and polluting the environment, so as to improve the impact force of crushing, improve crushing efficiency and , Prevent the effect of coagulation and agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

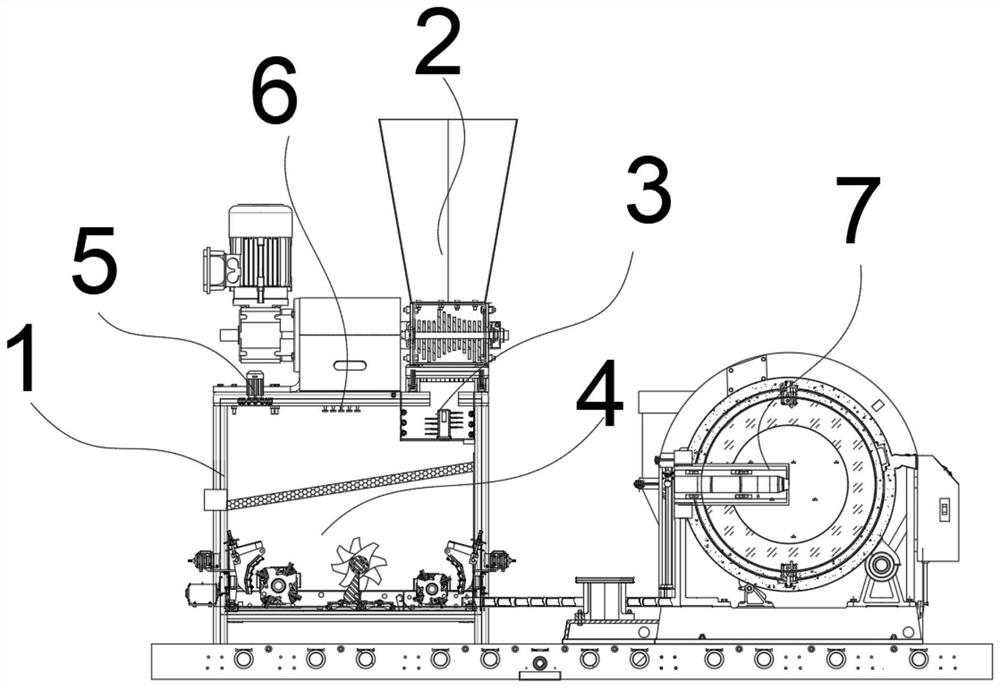

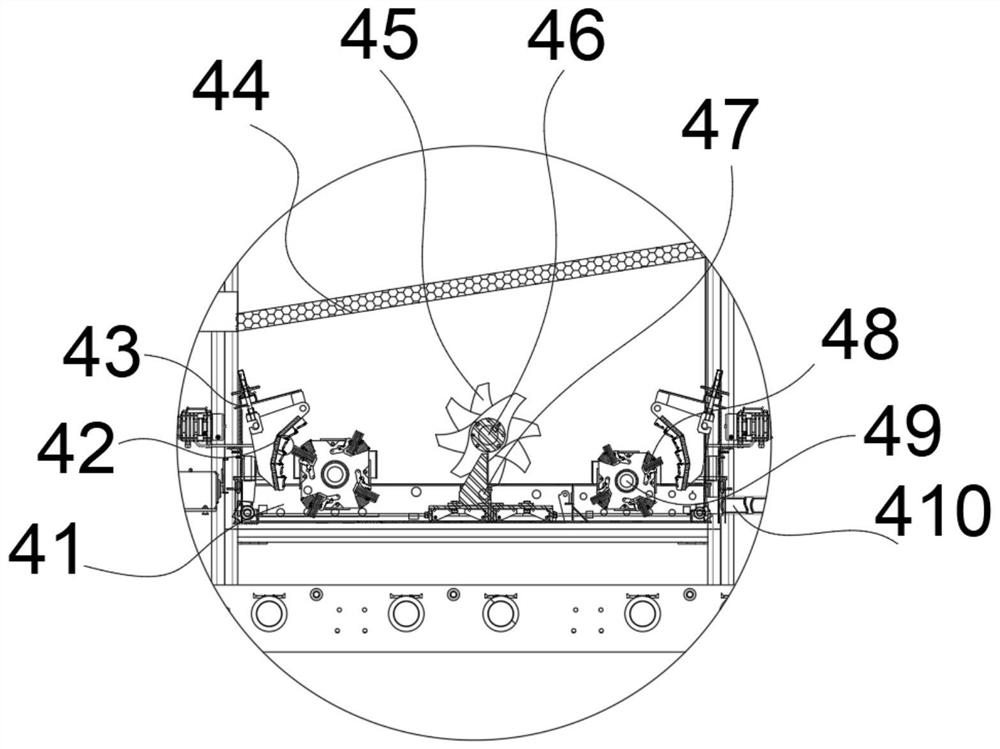

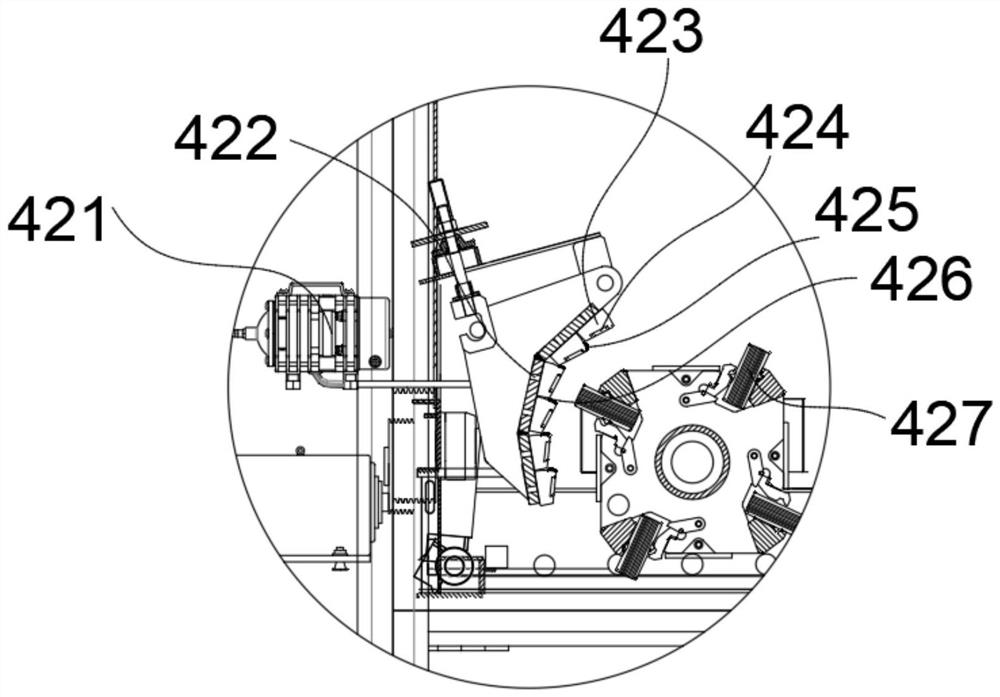

[0030] see figure 1 with figure 2 , in this embodiment, a special crushing box for waste recovery devices for environmental protection construction, which includes: a crushing box body 1, a primary crushing assembly 2, a magnetic separation assembly 3, a secondary crushing assembly 4, and an asphalt recovery box 7; The top of the crushing box 1 is fixed with a primary crushing assembly 2, and the bottom of the primary crushing assembly 2 is fixed with a magnetic separation assembly 3, and the magnetic separation assembly 3 is located in the crushing box 1, and the inner wall of the crushing box 1 The bottom is fixed with a secondary crushing assembly 4, and the discharge end of the secondary crushing assembly 4 is fixed with an asphalt recovery box 7. The secondary crushing assembly 4 includes at least an impact plate 42 and a screen 44, and the screen 44 can Large-diameter crushed stones are filtered, and the impact plate 42 breaks the asphalt by collision, and the waste as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com