Oral cavity fluid resinous material and preparation method thereof

A fluid resin and oral cavity technology, which is applied in the field of oral fluid resin material and its preparation, can solve the problems of oral fluid resin material without antibacterial and remineralization properties, etc., and achieves a simple and easy preparation method, beautiful appearance and uniform internal filler. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

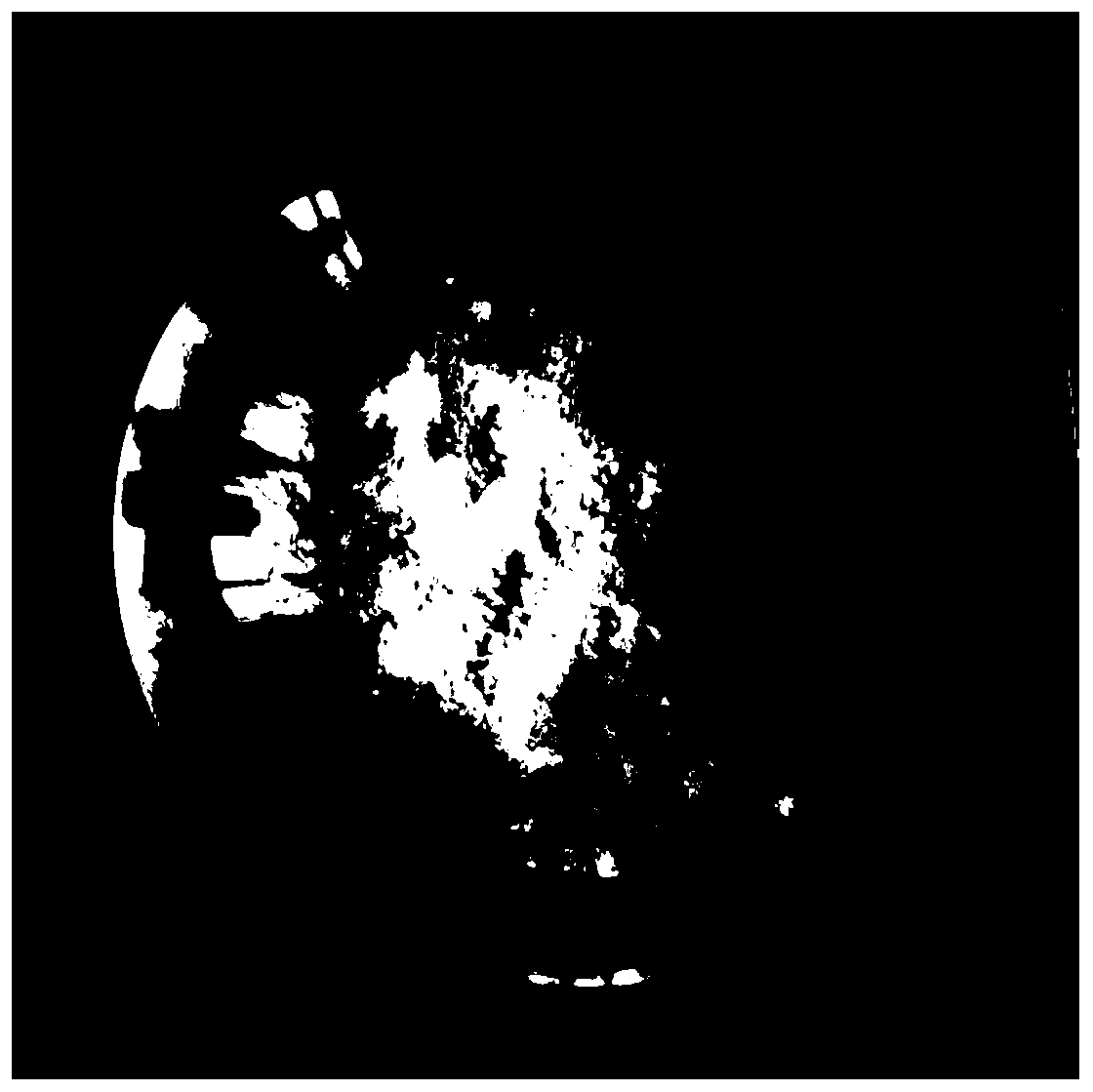

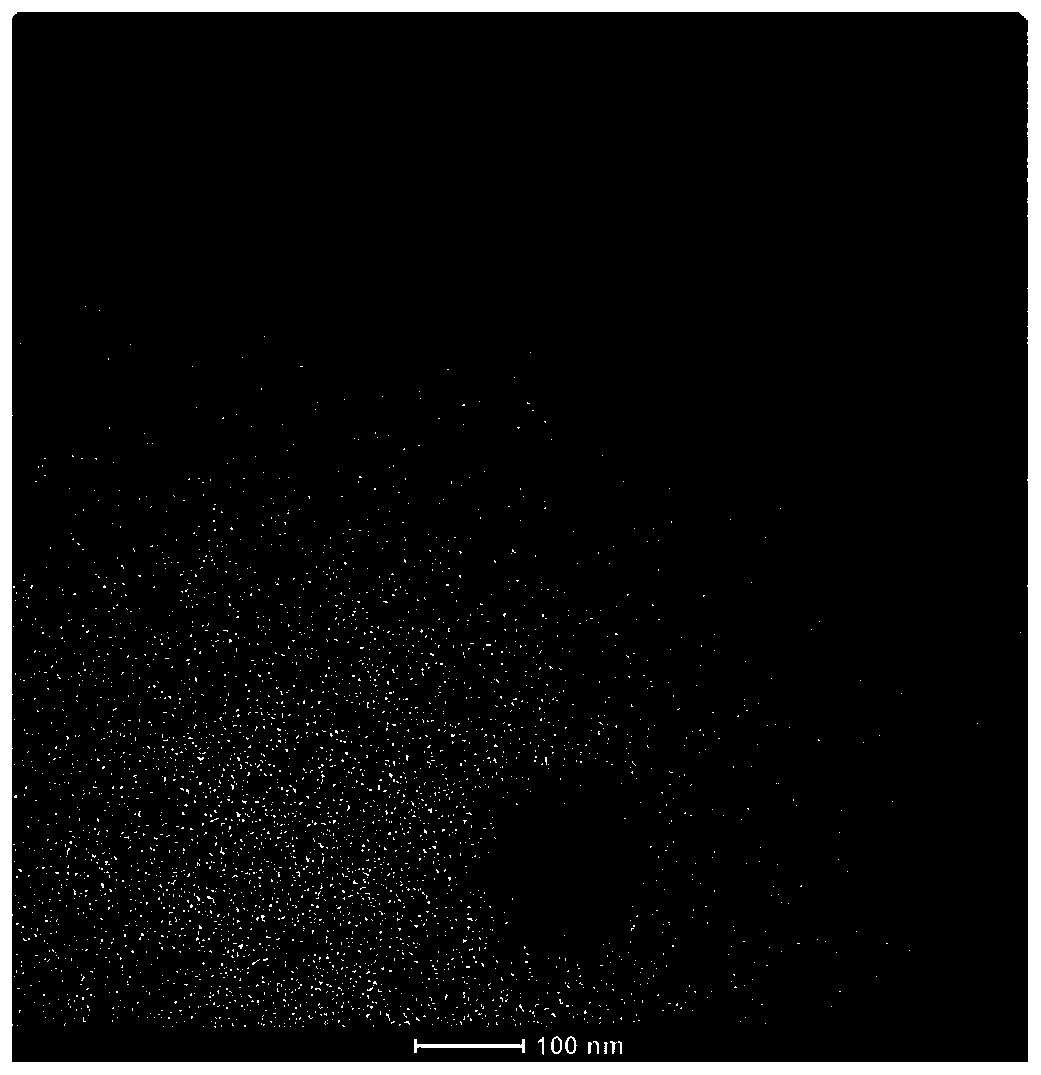

[0036]Under the condition of avoiding light, put 4.95g of liquid resin in a black plastic bottle for use. Add 0.05 g of core-shell CHX / ACP nanospheres into a black opaque plastic bottle under dark conditions, mix it evenly with a mixing knife, vacuumize to remove air bubbles, and store the obtained material in a sealed and dark place. As 1% CHX / ACP group. Fill the above resin into a cylindrical mold with a diameter of 10mm and a height of 1.5mm. The upper and lower surfaces of the mold are respectively covered with polyethylene film and glass slides, and the excess material is removed, cured with a light curing lamp for 20s, and the specimen is demoulded and placed for 24 hours spare.

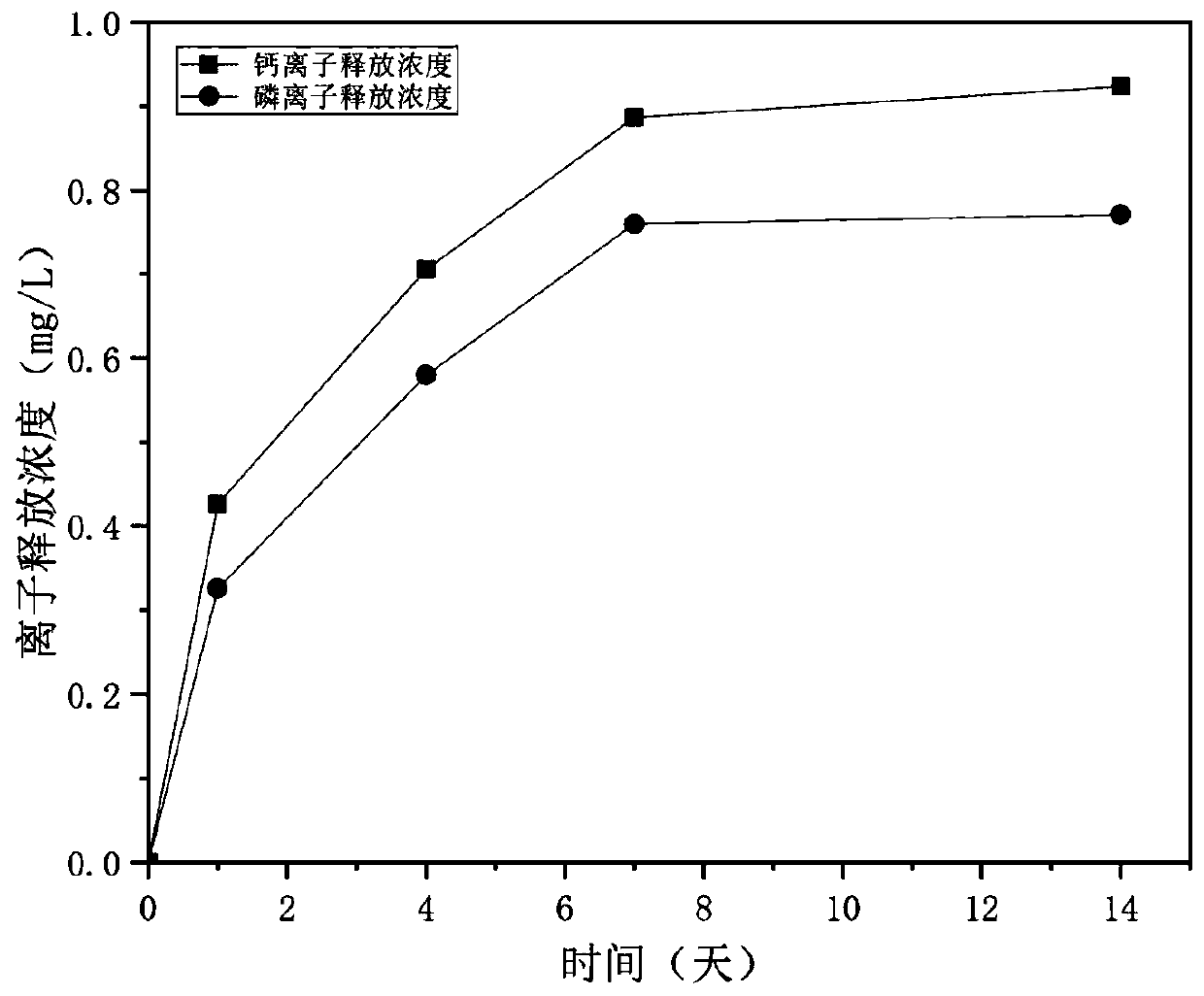

[0037] Soak the specimen in 10ml of deionized water, place it in a constant temperature box at 37°C, and soak for 1, 4, 7, and 14 days respectively. At each detection time point, the extract was collected for detection, and fresh deionized water was replaced to continue soaking. The concentr...

Embodiment 2

[0040] Under dark conditions, 4.75g of fluid resin was placed in a black plastic bottle for use. Add 0.25 g of core-shell CHX / ACP nanospheres into a black opaque plastic bottle under dark conditions, mix it evenly with a mixing knife, vacuumize to remove air bubbles, and store the obtained material in a sealed and dark place. As 5% CHX / ACP group. Fill the above resin into a cylindrical mold with a diameter of 10mm and a height of 1.5mm. The upper and lower surfaces of the mold are respectively covered with polyethylene film and glass slides, and the excess material is removed, cured with a light curing lamp for 20s, and the specimen is demoulded and placed for 24 hours spare.

[0041] Soak the specimen in 10ml of deionized water, place it in a constant temperature box at 37°C, and soak for 1, 4, 7, and 14 days respectively. At each detection time point, the extract was collected for detection, and fresh deionized water was replaced to continue soaking. The concentration of ...

Embodiment 3

[0044] Under dark conditions, 4.5g of clean resin was placed in a black opaque plastic bottle for later use. Add 0.5 g of core-shell CHX / ACP nanospheres into a black plastic bottle under dark conditions, mix it evenly with a mixing knife, vacuumize to remove air bubbles, and store the obtained material in a sealed and dark place, recorded as 10% CHX / ACP group. Fill the above resin into a cylindrical mold with a diameter of 10mm and a height of 1.5mm. The upper and lower surfaces of the mold are respectively covered with polyethylene film and glass slides, and the excess material is removed, cured with a light curing lamp for 20s, and the specimen is demoulded and placed for 24 hours spare.

[0045] Soak the specimen in 10ml of deionized water, place it in a constant temperature box at 37°C, and soak for 1, 4, 7, and 14 days respectively. At each detection time point, the extract was collected for detection, and fresh deionized water was replaced to continue soaking. The con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com