Non-supporting magnetic suspension type omnidirectional 3D printing system and method

A 3D printing and suspension technology, applied in 3D object support structure, additive manufacturing, processing data acquisition/processing, etc., can solve problems such as imperfect structure of suspension device, limitation of printing position and angle, low printing efficiency, etc., to achieve Rich printing process control and status monitoring functions, precise electromagnetic force control, and precise printing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

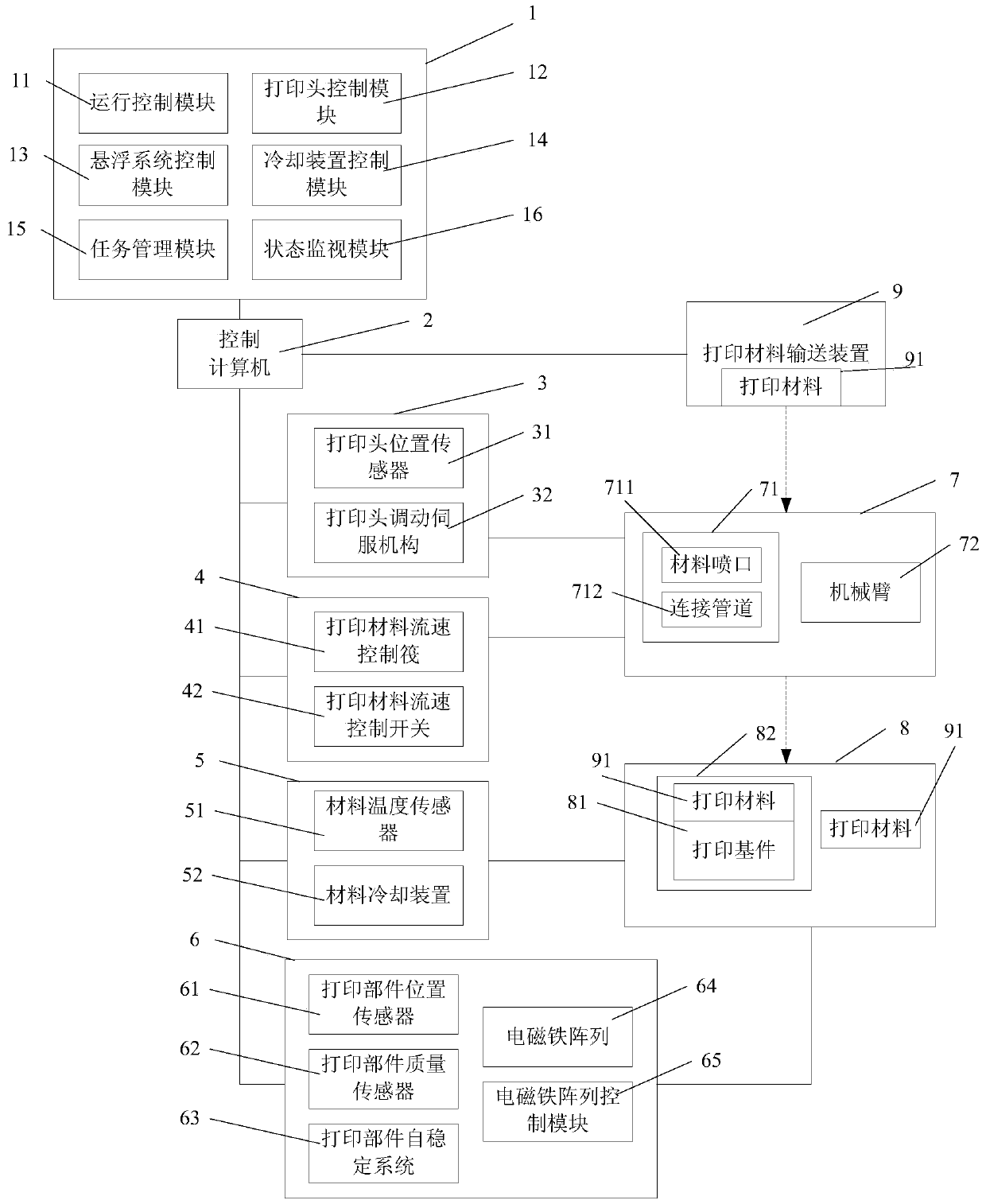

specific Embodiment 1

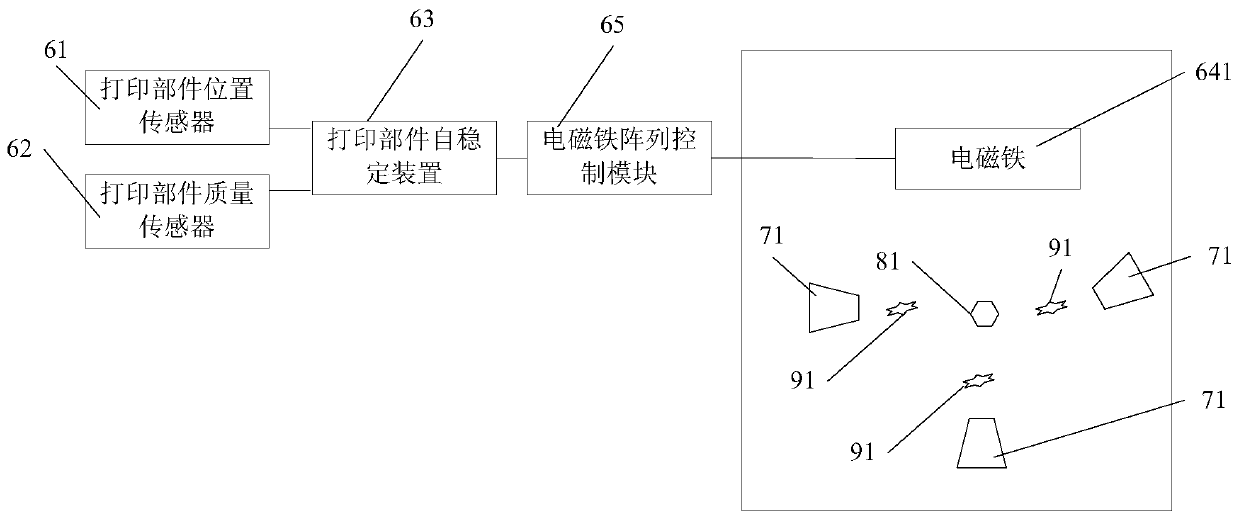

[0053] A schematic diagram of a magnetic levitation omnidirectional 3D printing system with a single electromagnet, as attached image 3 As shown, the printing part suspension device 6 of the 3D printing system includes: a printing part position sensor 61, a printing part quality sensor 62, a printing part self-stabilizing system 63, an electromagnet array control module 65, an electromagnet 641; The self-stabilizing system 63 is connected to the printing part position sensor 61 and the printing part quality sensor 62 through the data line, and the electromagnet array control module 65 is connected to the printing part self-stabilizing system 63 through the data line; the electromagnet array control module 65 is connected to the electromagnet 641 through the power line , the electromagnet array control module 65 can control the voltage and phase of the electromagnet 641 . as attached image 3 As shown, the printing component 8 of the 3D printing system includes a printing sub...

specific Embodiment 2

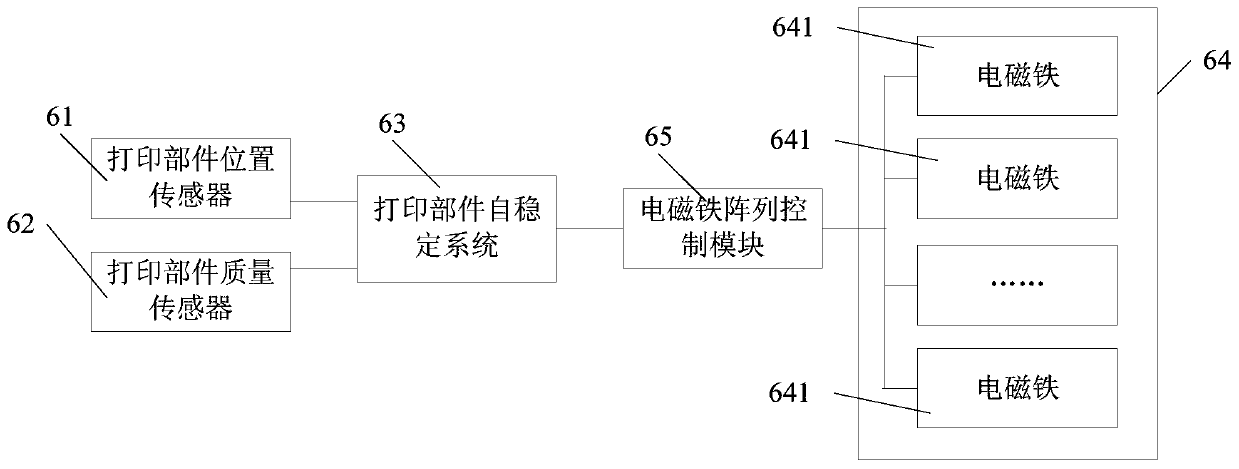

[0056] A schematic diagram of an electromagnet array magnetic levitation omnidirectional 3D printing system, as attached Figure 4 As shown, the printing part suspension device 6 of the 3D printing system includes: a printing part position sensor 61, a printing part quality sensor 62, a printing part self-stabilizing system 63, an electromagnet array 64 and an electromagnet array control module 65, and the electromagnet Array 64 is made up of a plurality of electromagnets 641, and a plurality of electromagnets 641 is arranged to form an electromagnet array 64, and described electromagnet array 64 is positioned at the upper part of printing space; Printing component self-stabilizing system 63 connects printing component position sensor 61 through data line The printing part quality sensor 62 and the electromagnet array control module 65 are connected to the printing part self-stabilizing system 63 through data lines; the electromagnet array control module 65 is connected to a plur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com