A kind of modified bamboo fiber asphalt mixture and preparation method thereof

A technology for asphalt mixture and asphalt binder, which is applied in the field of road engineering materials, can solve the problems affecting the durability of asphalt mixture, the difference in interface compatibility and dispersion uniformity, and the limited use range, and achieves low cost, hydrophobicity and other problems. Enhanced performance, simple and easy-to-operate preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

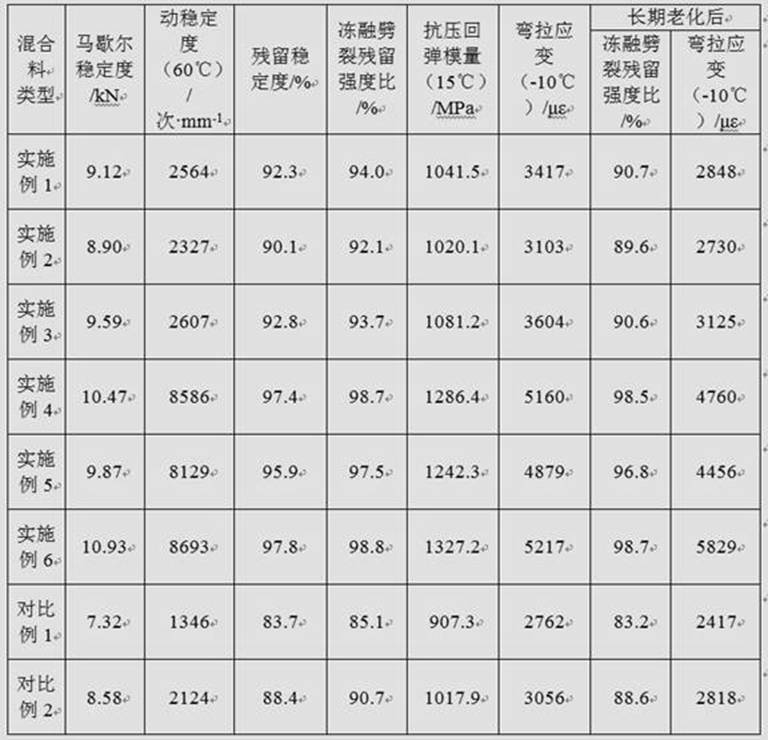

Examples

Embodiment 1

[0026] A preparation method for modified bamboo fiber asphalt mixture, comprising the following steps:

[0027] Step 1, soaking the bamboo fibers in a 0.2% benzoic acid solution for 100 minutes, placing the treated bamboo fibers in an oven at 110°C for 3 hours to fully carry out the modification reaction, and placing the modified bamboo fibers The fiber is rubbed and milled for the second time to obtain the modified bamboo fiber, which is set aside;

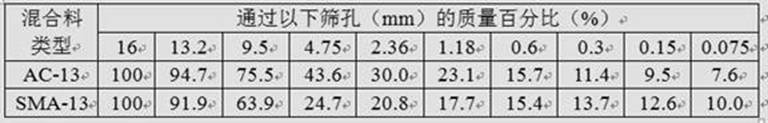

[0028] Step 2: Preheat the coarse and fine aggregates in the AC-type asphalt mixture in an oven at 170°C for 4 hours, then move them to a mixing pot at 170°C for 40 seconds, and then mix the modified bamboo fiber prepared in step 1 After mixing with the pre-mixed aggregate, dry mix for 80s to obtain asphalt binder;

[0029] Step 3: Preheat the asphalt binder prepared in step 2 to 150°C and add it to the mixing pot for wet mixing for 80s, then add mineral powder preheated to 150°C and mix for 80s to prepare AC-type modified bambo...

Embodiment 2

[0032] Step 1, soaking the bamboo fiber in a 0.3% benzoic acid solution for 120 minutes, placing the treated bamboo fiber in an oven at 115°C for 2.5 hours to fully carry out the modification reaction. Bamboo fibers are rubbed and milled for the second time to obtain modified bamboo fibers for subsequent use;

[0033] Step 2: Preheat the coarse and fine aggregates in the AC-type asphalt mixture in an oven at 175°C for 4.5 hours, then move them to a mixing pot at 175°C for pre-mixing for 50 seconds, and then mix the modified bamboo aggregates prepared in step 1 After the fiber is mixed with the pre-mixed aggregate, it is dry-mixed for 80 seconds to obtain the asphalt binder;

[0034] Step 3: Preheat the asphalt binder prepared in step 2 to 155°C and add it to the mixing pot for wet mixing for 80s, then add mineral powder preheated to 155°C and mix for 80s to prepare AC-type modified bamboo fiber asphalt Mixture.

[0035] In embodiment 2, the modified bamboo fiber length that ...

Embodiment 3

[0037] Step 1, placing the bamboo fiber in a benzoic acid solution with a concentration of 0.4% and soaking it for 140 minutes, placing the treated bamboo fiber in an oven at 120°C for 3.5 hours to fully carry out the modification reaction, and placing the modified bamboo fiber Bamboo fibers are rubbed and milled for the second time to obtain modified bamboo fibers for subsequent use;

[0038] Step 2: Preheat the coarse and fine aggregates in the AC-type asphalt mixture in an oven at 170°C for 5 hours, then move them to a mixing pot at 170°C for pre-mixing for 60 seconds, and then mix the modified bamboo fiber prepared in step 1 Mix with the pre-mixed aggregate and dry mix for 100s to obtain asphalt binder;

[0039]Step 3: preheat the asphalt binder prepared in step 2 to 160°C and add it to the mixing pot for wet mixing for 100s, then add mineral powder preheated to 160°C and mix for 100s to prepare AC-type modified bamboo fiber asphalt Mixture.

[0040] In embodiment 3, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com