High-efficiency recycling process of ethyl acetate resin

A technology of ethyl acetate and resin, which is applied in the field of high-efficiency ethyl acetate resin recycling technology, can solve problems such as low production efficiency and poor product quality, reduce material waste and recycling costs, improve work efficiency and precision, and simplify the recycling process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

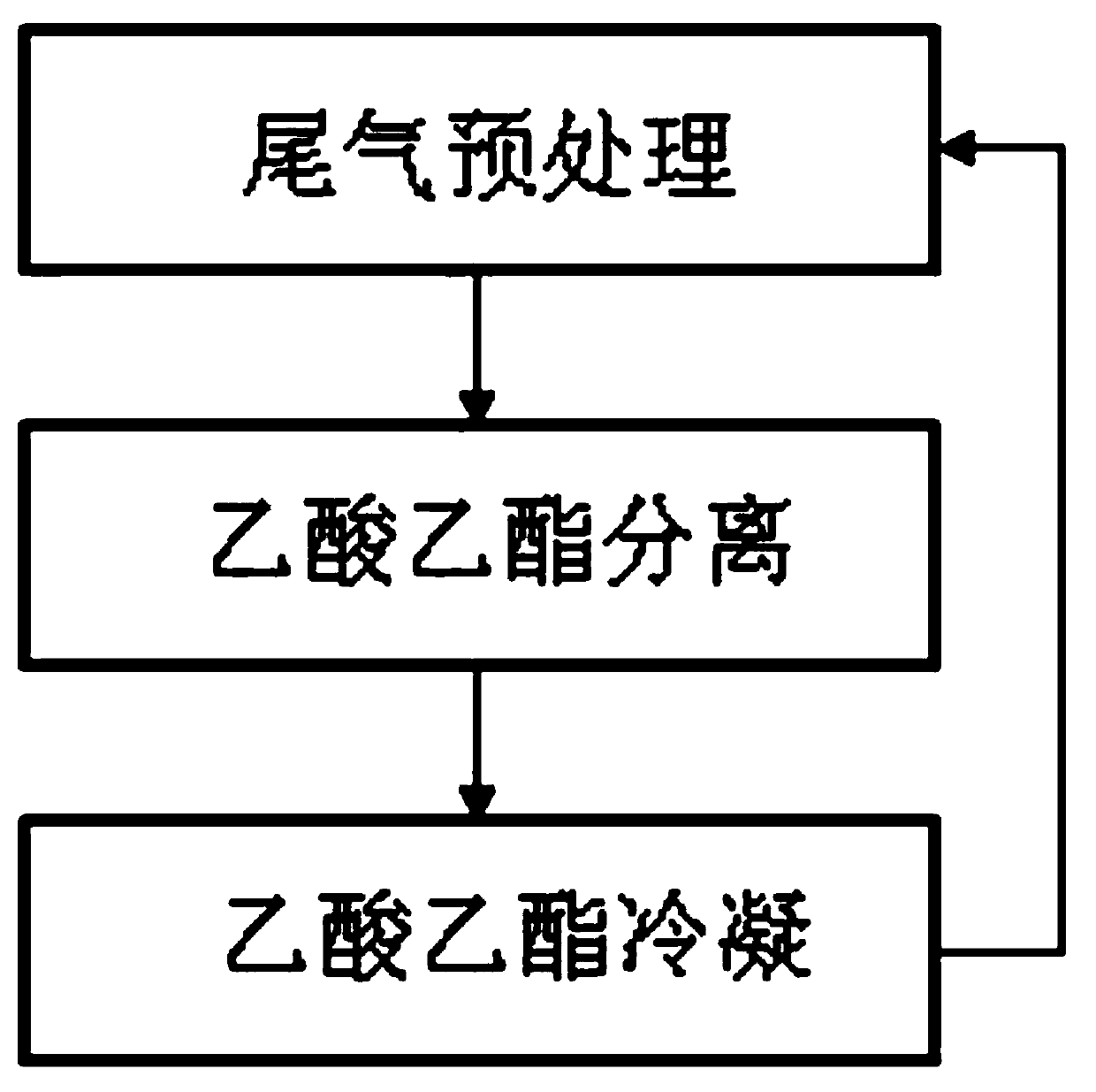

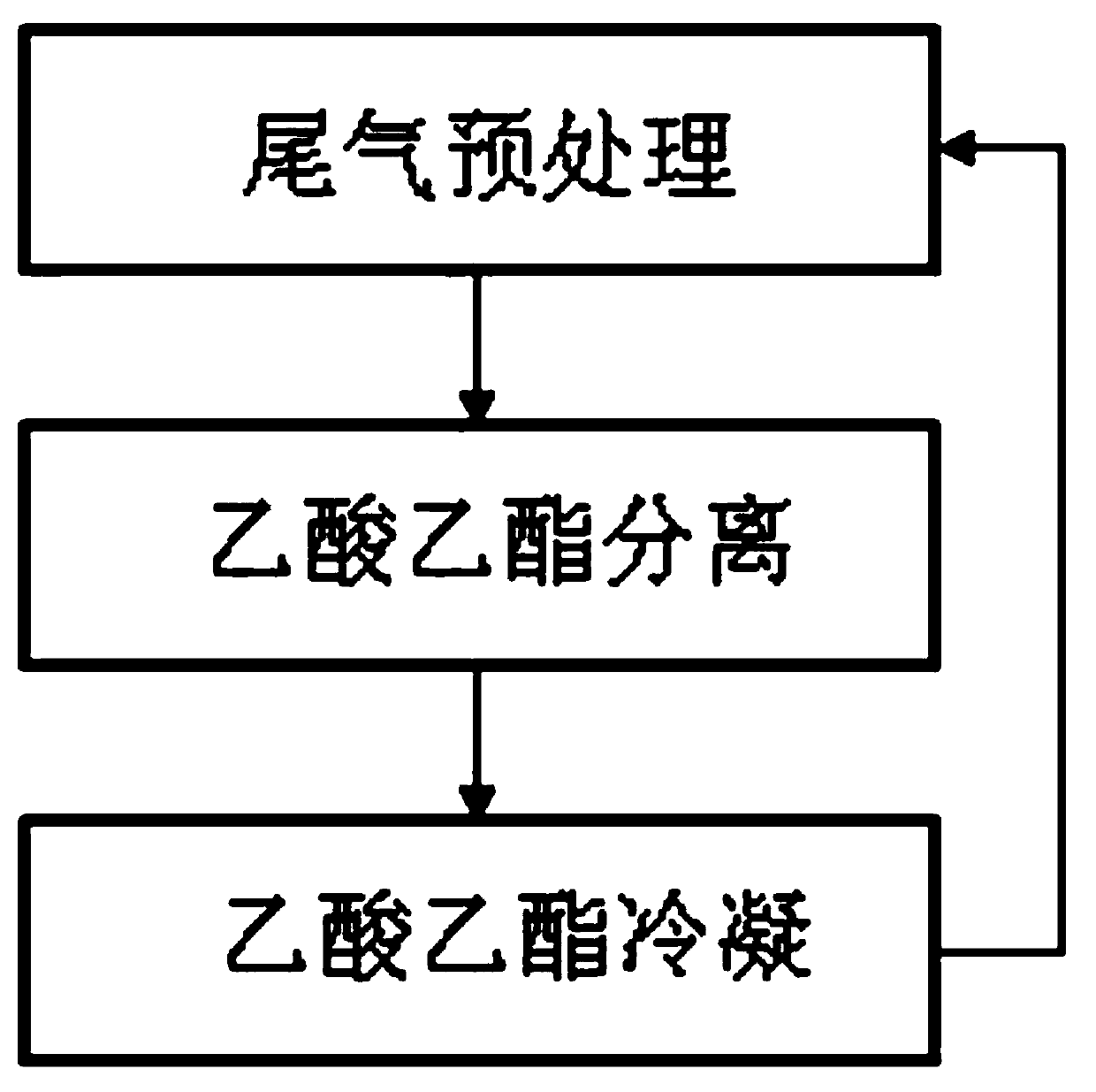

[0017] Such as figure 1 Shown a kind of efficient ethyl acetate resin recovery process, comprises the steps:

[0018] The first step is tail gas pretreatment. The tail gas containing ethyl acetate is firstly filtered and separated from solid pollutants, and then the separated tail gas is transported to the tail gas buffer tank, and the collected tail gas is irradiated through the tail gas buffer tank. Heating to keep the temperature of the exhaust gas at 40°C, and the pressure in the exhaust buffer tank at 0.8 times the standard atmospheric pressure;

[0019] In the second step, ethyl acetate is separated, and the tail gas buffered in the first step tail gas buffer tank is pressurized to 3 times the standard atmosphere through a booster pump, and then transported to the resin adsorption tower with a constant working temperature of 30 ° C, and the air flow along the The axis of the resin adsorption tower passes through the resin adsorption tower from bottom to top, and after t...

Embodiment 2

[0025] Such as figure 1 Shown, a kind of high-efficiency ethyl acetate resin recovery process comprises the steps:

[0026] The first step is tail gas pretreatment. The tail gas containing ethyl acetate is firstly filtered and separated from solid pollutants, and then the separated tail gas is transported to the tail gas buffer tank, and the collected tail gas is irradiated through the tail gas buffer tank. Heating to keep the exhaust gas temperature constant at 60°C and the pressure in the exhaust buffer tank constant at 1.5 times the standard atmospheric pressure;

[0027] In the second step, ethyl acetate is separated, and the tail gas buffered in the first step tail gas buffer tank is pressurized to 15 times the standard atmosphere through a booster pump, and then transported to the resin adsorption tower with a constant working temperature of 60 ° C, and the air flow along the The axis of the resin adsorption tower passes through the resin adsorption tower from bottom to...

Embodiment 3

[0033] A kind of high-efficiency ethyl acetate resin recovery process, comprises the steps:

[0034] The first step is tail gas pretreatment. The tail gas containing ethyl acetate is firstly filtered and separated from solid pollutants, and then the separated tail gas is transported to the tail gas buffer tank, and the collected tail gas is irradiated through the tail gas buffer tank. Heating to keep the exhaust gas temperature constant at 50°C and the pressure in the exhaust buffer tank constant at 1.1 times the standard atmospheric pressure;

[0035] In the second step, ethyl acetate is separated, and the tail gas buffered in the first step tail gas buffer tank is pressurized to 8 times the standard atmosphere through a booster pump, and then transported to a resin adsorption tower with a constant working temperature of 40°C, and the airflow is made along the The axis of the resin adsorption tower passes through the resin adsorption tower from bottom to top, and after the et...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com