Quantum dot ink and preparation method thereof

A technology of quantum dots and quantum dot materials, which is applied in the field of quantum dot ink and its preparation, can solve the problems of low efficiency of light-emitting devices, and achieve the effect of improving current efficiency and uniform film formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0061] The preparation method of above-mentioned quantum dot ink comprises:

[0062] Weigh each raw material according to the above weight ratio

[0063] The quantum dot material and acceptor material are placed in the beaker;

[0064] Add two-thirds of the required polar solvent and stir evenly to completely dissolve the quantum dot material and acceptor material;

[0065] Add the remaining polar solvent, stir and dilute to obtain quantum dot ink.

[0066] By adjusting the component content of each raw material in the above-mentioned quantum dot ink, the quantum dot ink whose viscosity and surface tension can be applied to the requirements of inkjet printing equipment and printing process conditions is obtained, so as to ensure uniform film formation of inkjet printing.

[0067] The quantum dot ink and its preparation method of the present invention will be further described in detail below in conjunction with specific embodiments.

Embodiment 1

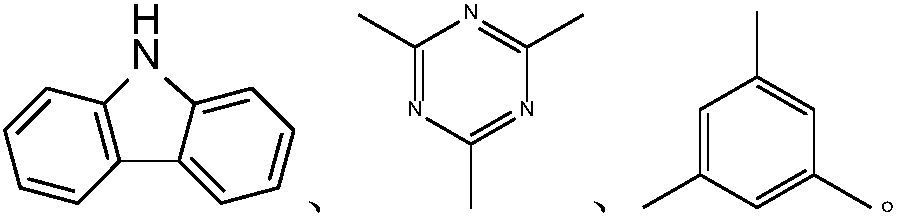

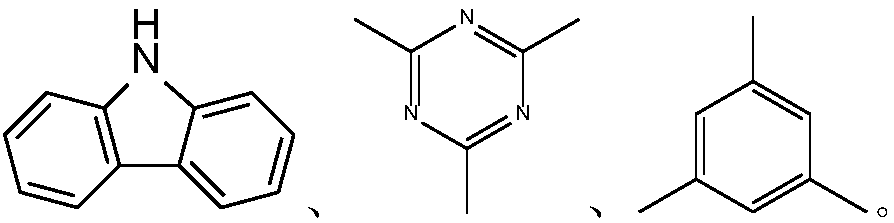

[0069] This embodiment provides a QLED device, which includes a stacked anode, a functional layer containing m-MTDATA as a donor material, a light emitting layer and a cathode.

[0070] Wherein, the luminescent layer is prepared by ink-jet printing of quantum dot ink.

[0071] The above-mentioned quantum dot ink is composed of CdSe / ZnS quantum dots, 1,3,5-tris(m-pyridin-3-ylphenyl)benzene (TmPyPB), chlorobenzene and tetralin. Among them, CdSe / ZnS quantum dots account for 7% of the total weight of the ink, 1,3,5-tris(m-pyridin-3-ylphenyl)benzene accounts for 3% of the total weight of the ink, and chlorobenzene accounts for 56% of the total weight of the ink. %, tetralin accounts for 34% of the total weight of the ink.

[0072] After accurate weighing, place CdSe / ZnS quantum dots and 1,3,5-tris(m-pyridin-3-ylphenyl)benzene in a 250ml flask, add the pre-configured mixture of chlorobenzene and tetralin The mixed polar solvent of composition, the amount that adds is two-thirds of...

Embodiment 2

[0074] This embodiment provides a QLED device, which includes a stacked anode, a functional layer containing m-MTDATA as a donor material, a light emitting layer and a cathode.

[0075] Wherein, the luminescent layer is prepared by ink-jet printing of quantum dot ink.

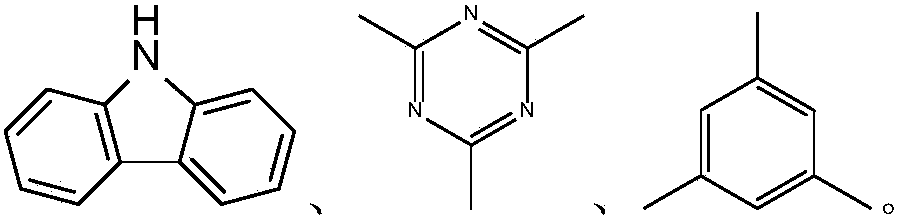

[0076] The above-mentioned quantum dot ink is composed of CdSe / ZnS quantum dots, TmPyTZ, chlorobenzene and tetralin. Among them, CdSe / ZnS quantum dots account for 7% of the total ink weight, TmPyTZ accounts for 3% of the total ink weight, chlorobenzene accounts for 56% of the total ink weight, and tetralin accounts for 34% of the total ink weight.

[0077] After accurate weighing, put CdSe / ZnS quantum dots and TmPyTZ in a 250ml flask, add a pre-configured mixed polar solvent composed of chlorobenzene and tetralin, the amount added is 1 / 3 of the required volume 2. Stir to dissolve the material completely. After that, add the remaining solvent, stir and dilute, and the product is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com