Memory alloy based nano laminated composite material and preparation method thereof

A memory alloy and nano-layered technology, which is applied in the field of composite materials with memory function and its preparation, can solve the problems of dislocation movement hindrance, strength and toughness opposition, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

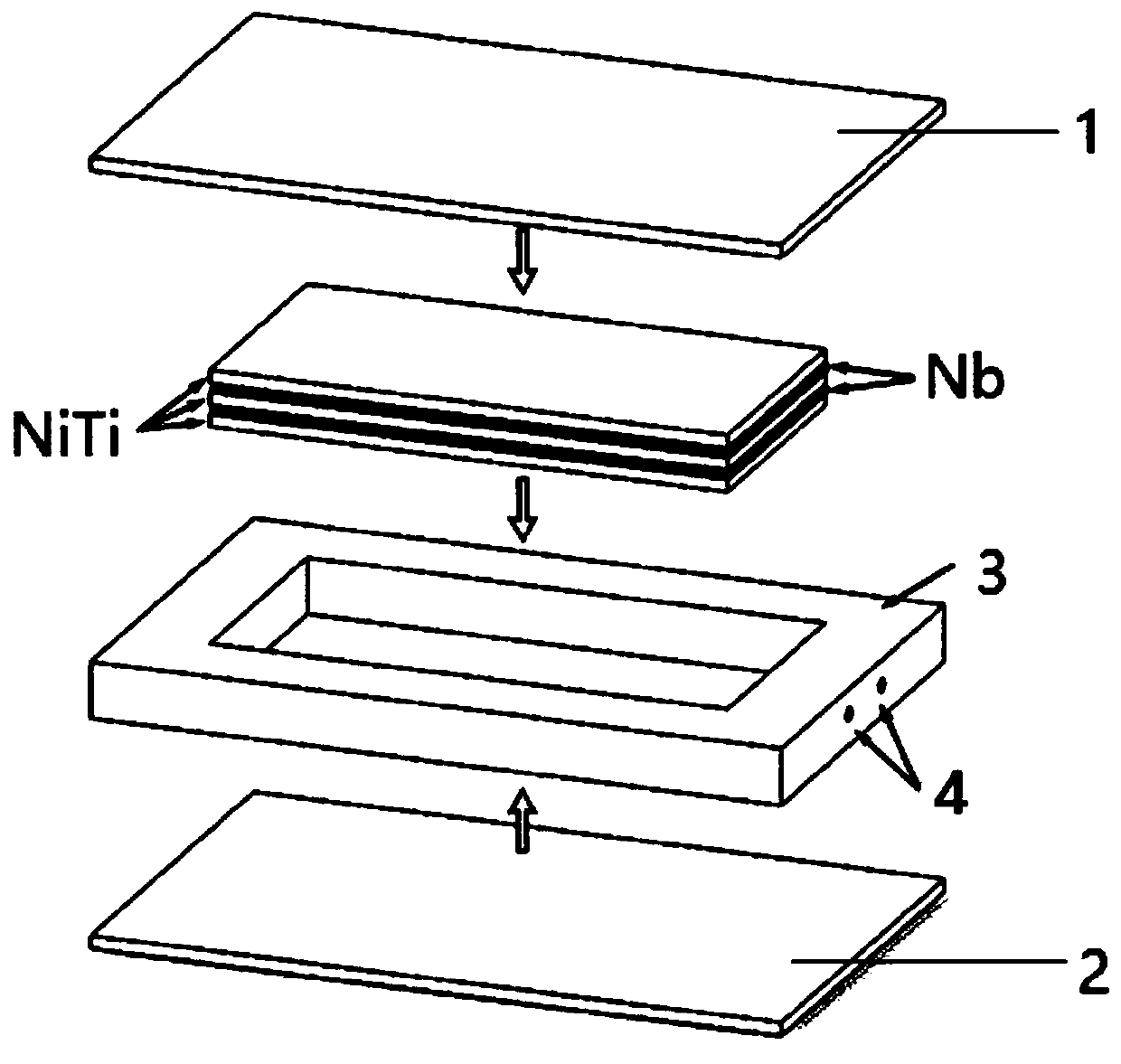

[0050] In this embodiment, specifically, Nb is used as the reinforcing phase and NiTi shape memory alloy is used as the matrix. The specific NiTi shape memory alloy is a NiTi alloy with a Ni content of 50.1 at%. The NiTi shape memory alloy and the reinforcing phase metal Alternately arranged in sheets and layers to form a layered composite material, thereby forming a Nb-NiTi nano-layered composite material.

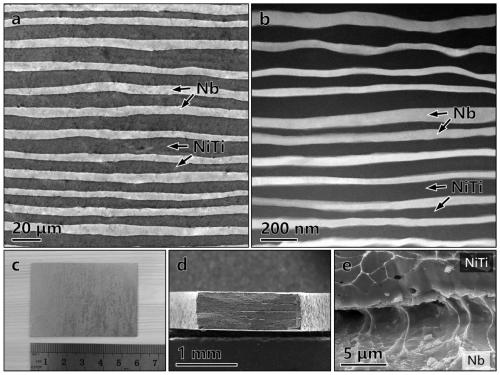

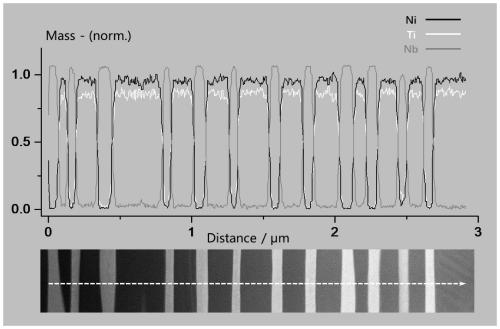

[0051] See attached figure 2 , Figure a is a cross-sectional scanning electron microscope picture of a Nb-NiTi nanolayer composite material with a Nb sheet thickness of about 10 μm after the first two passes, and Figure b is a Nb-NiTi nanometer composite material with a Nb sheet thickness of about 60 nm. High Angle Annular Dark Field (HAADF) picture of the cross-sectional transmission electron microscope of the layered composite material. It can be seen that the Nb reinforcement phase and the NiTi alloy matrix phase are alternately distributed in sheets, and the Nb phase...

Embodiment 2

[0069] For Cu-NiTi memory alloy-based nano-layered composites, due to the low melting points of Cu and Ni, it is necessary to appropriately reduce the processing temperature in step (6) to about 700 °C. At this time, the plasticity of NiTi will decrease, so it is necessary to At the same time, the amount of deformation in a single pass is appropriately reduced, for example, the amount of deformation in a single pass is not higher than 50%, that is, the range of deformation in a single pass is 40-50%, preferably 45%.

[0070] Materials obtained in this embodiment are shown in Figure 5 In a, the thickness of the reinforcing phase Cu layer is about 7 μm, and the volume fraction of the reinforcing phase is 35%. Repeating steps (2) to (7) can further obtain a material with a reinforcing phase of nanoscale thickness.

Embodiment 3

[0072] For the Ta-NiTi memory alloy-based nano-layered composite material, the physical properties and mechanical properties of Ta are close to those of Nb, so the specific implementation method of preparing Ta-NiTi is the same as the above-mentioned preparation method of Nb-NiTi.

[0073] Materials obtained in this embodiment are shown in Figure 5 In b, the thickness of the reinforcing phase tantalum layer is about 11.5 μm, and the volume fraction of the reinforcing phase is 48%. Repeating steps (2) to (7) can further obtain a material with a reinforcing phase of nanoscale thickness.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com