An Electric Proportional Load Sensing Multi-way Valve with Integrated Hydraulic Lock

A load-sensitive, electric proportional technology, applied in the direction of fluid pressure actuators, servo motor components, mechanical equipment, etc., can solve the problems of high labor intensity, reduced service life, and many leakage points, so as to improve work reliability and reduce Leakage risk, effect of improving control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

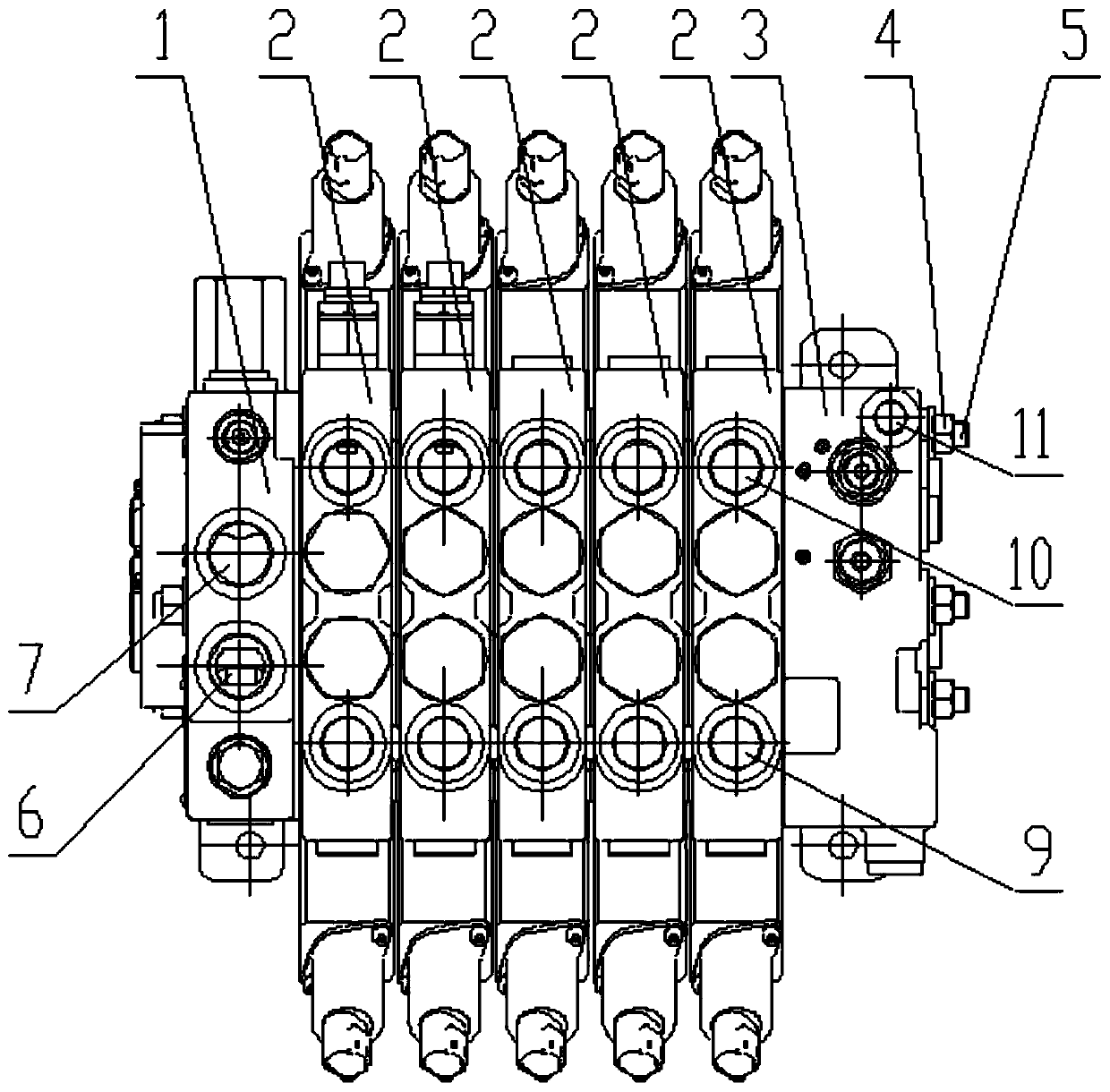

[0038] like figure 1 Shown is the overall structure of the electric proportional load sensitive multi-way valve with integrated hydraulic lock of the present invention, including oil inlet joint 1, several working joints 2, tail joint 3, double-ended stud 5 and nut 4, through which the double-ended stud 5 Assemble the oil inlet unit 1, multiple working units 2 and tail unit 3 with the nut 4, the oil inlet unit 1 is provided with the oil inlet P port 6 and the oil return port T port 7; the working unit 2 is respectively provided with the working oil A Port 9, working oil B port 10; tail joint 3 is provided with a pilot pressure drain port 11.

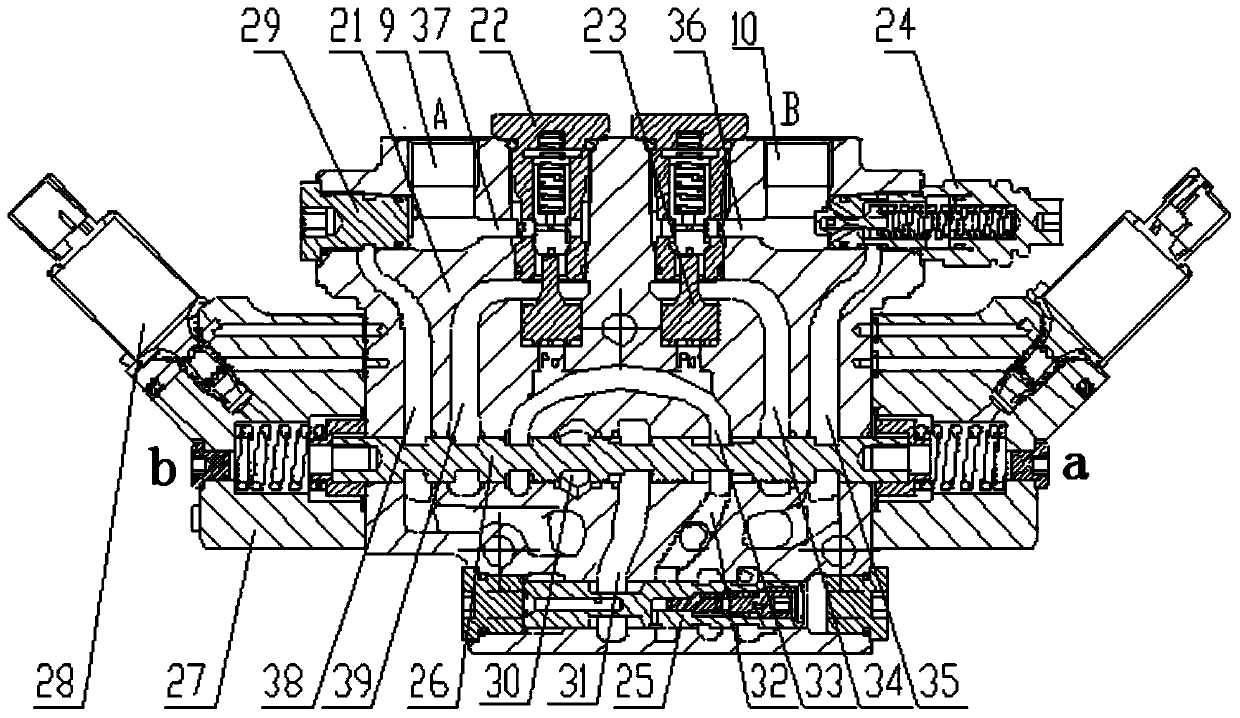

[0039] combine figure 2 Shown is the sectional v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com