Reflecting mirror array with normal gauge guide

A mirror array and lens technology, applied in the field of mirrors, can solve the problems of reduced reflection efficiency of the array, ineffective protection, urban light pollution, etc., and achieve the effects of reducing driving power and wear, keeping the mirror surface bright, and improving the flushing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Below in conjunction with embodiment, the present invention will be further described:

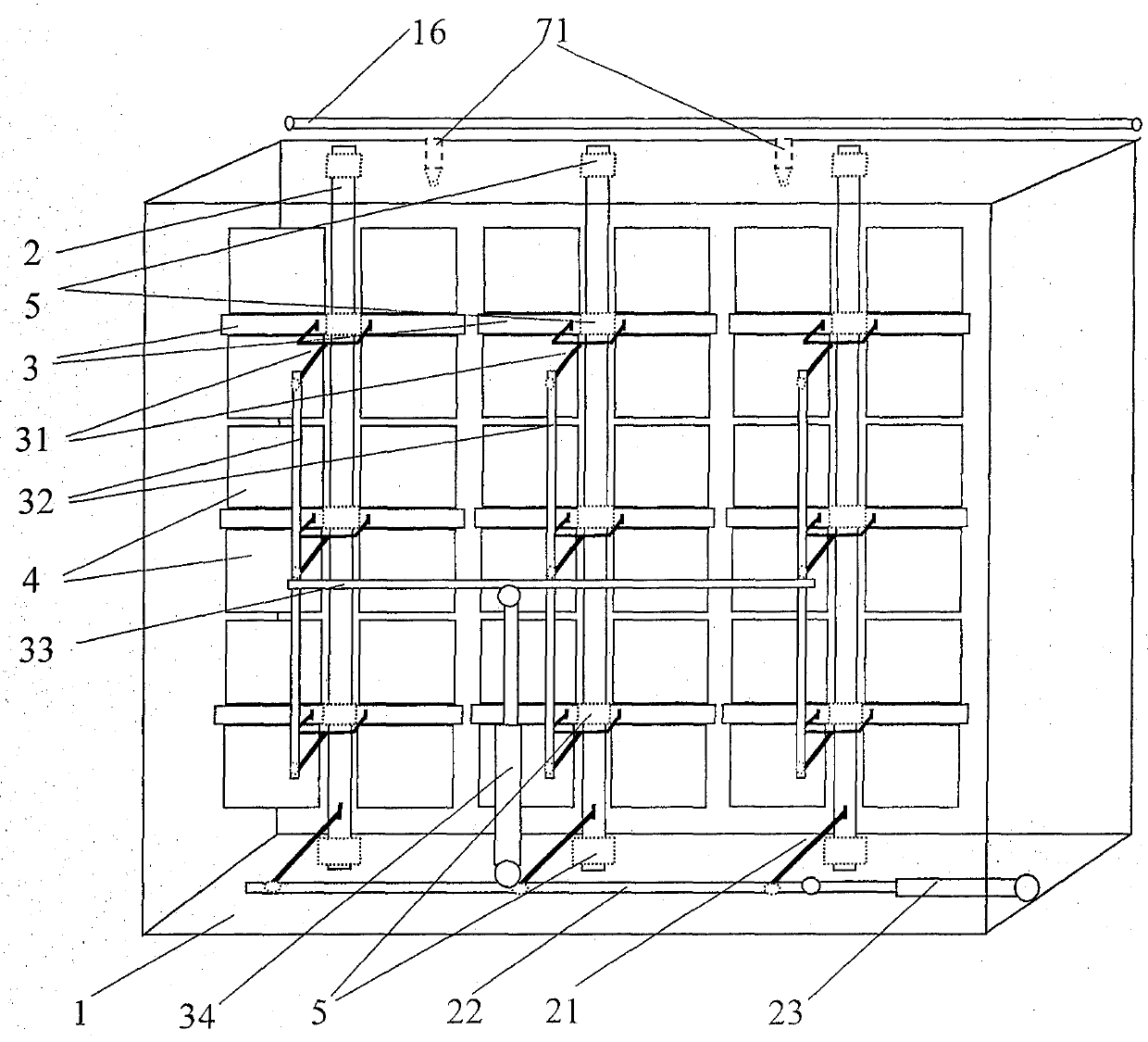

[0054] figure 1 It is a schematic diagram of the overall structure of an embodiment of the present invention. This normal guide mirror array includes a frame (1) and at least two vertical shafts (2), and each vertical shaft (2) is connected to at least two horizontal shafts (3 ), each horizontal axis (3) is symmetrically fixed up and down, left and right, and one piece of the same specification and the same material sunlight reflective lens (4) is fixed, as shown in the figure, there are 3 vertical axes, so that the middle vertical axis is the center of symmetry, and the size of the lens (4) can be Determine according to needs, such as 200x200mm, then the lenses (4) on the 2 horizontal axes on every 2 vertical axes, plus the space occupied by the axes themselves and the gap between the lenses, are about 1 square meter in total; it should be noted that , after installation and debug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com