A kind of graphite silicon carbide thermocouple protective sleeve and preparation method thereof

A silicon carbide and thermocouple technology, applied in the direction of measuring heat, instruments, thermometer parts, etc., can solve the problems of short service life, weak oxidation resistance and corrosion resistance of protective sleeve, etc., to improve product qualification rate and parameters The effect of low control difficulty and less pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

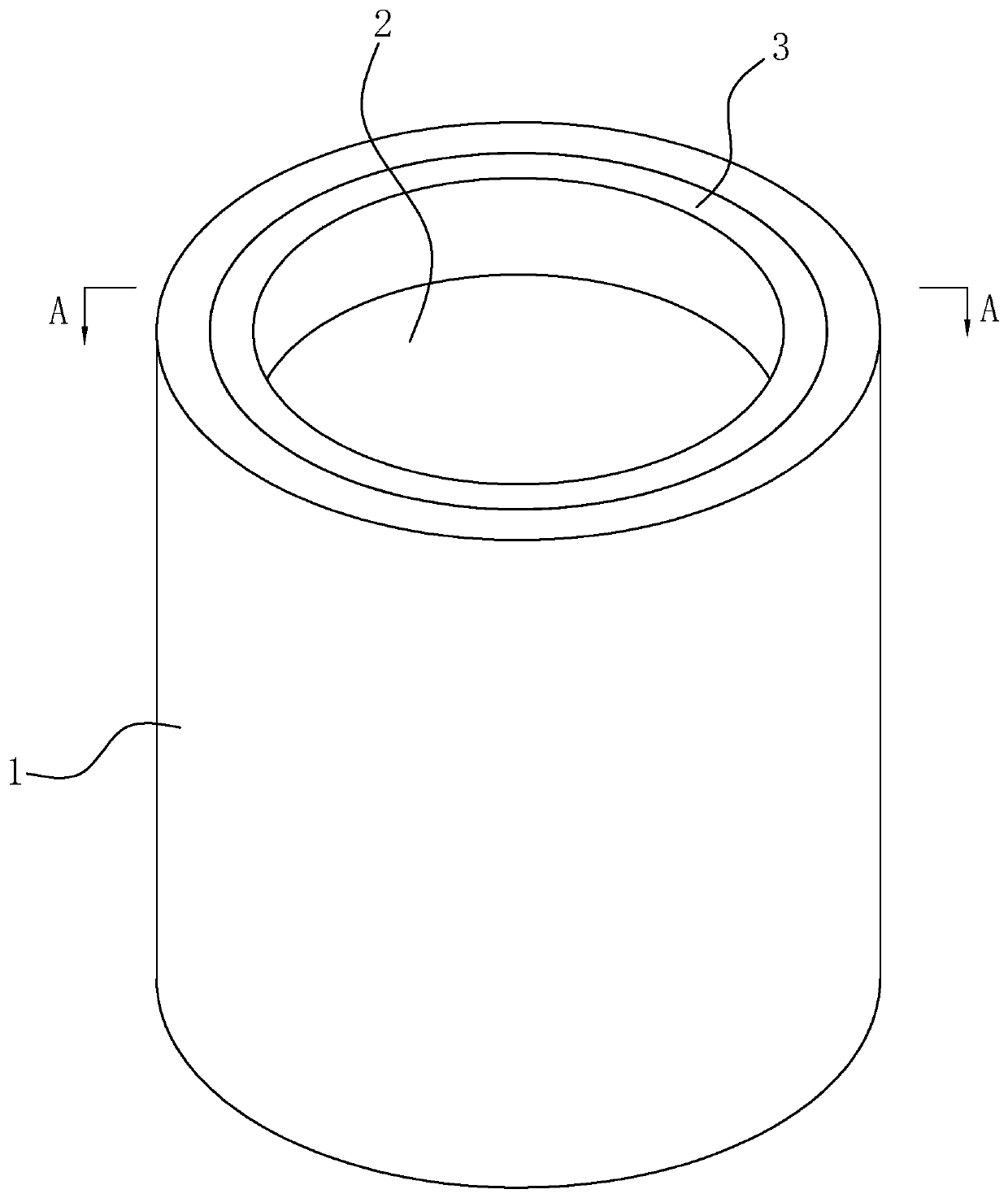

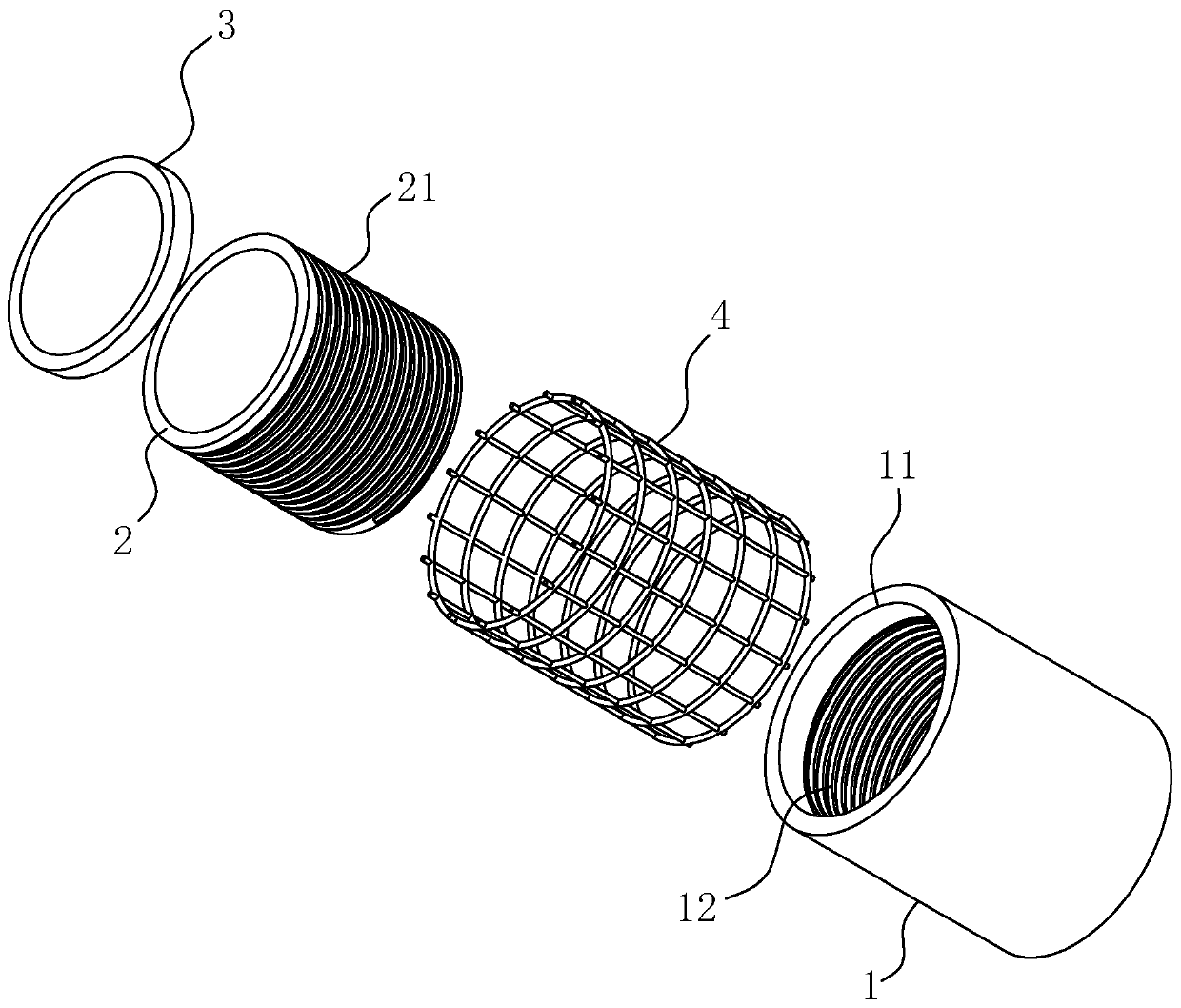

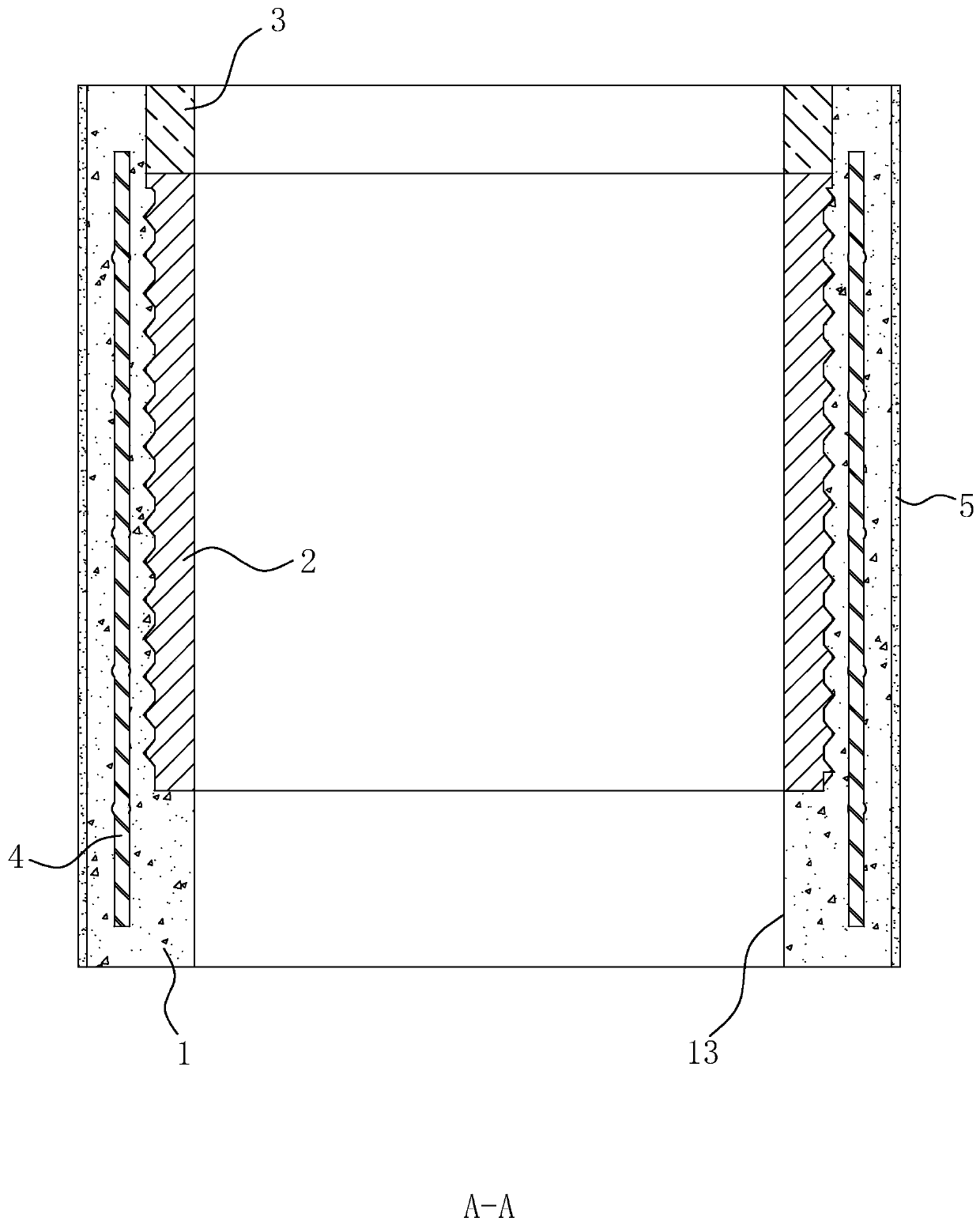

[0039] Embodiment one: a kind of graphite silicon carbide thermocouple protection sleeve, such as figure 1 with figure 2 As shown, the graphite tube body 1 is included, and a metal mesh 4 is installed inside the graphite tube body 1. The graphite tube body 1 is provided with a central hole 13 along the axial direction, and the inner wall of the graphite tube body 1 is located in the middle of the central hole 13. -SiC composite layer 2, one end of the graphite tube body 1 is located on the inner wall of the central hole 13, and a C-C composite layer 3 is provided.

[0040] refer to figure 2 with image 3 1. Increase the diameter of the central hole 13 at one end of the graphite tube body 1 to form a reaming hole 11, and the middle part of the reaming hole 11 is provided with an internal thread 12 10-20mm away from the end face. The surface of the C / C-SiC composite layer 2 is provided with a spiral rib 21 along the axial direction, and the rib 21 cooperates with the intern...

Embodiment 2

[0043] Embodiment two: a kind of preparation method of graphite silicon carbide thermocouple protective cover, comprises the following steps:

[0044] S1: Filling density in a cylindrical mold with an inner diameter of 100mm and a height of 180mm is 0.20g / cm 3 Graphite powder, the fixed carbon of graphite powder is not less than 95%, the particle size is 70 mesh, and the density of press molding is 1.60g / cm 3 The graphite tube body 1 has a wall thickness of 30 mm; the graphite tube body 1 is integrally formed with a central hole 13 and a reaming hole 11 .

[0045] S2: Take the graphite tube body 1 out of the mold, clean up the graphite powder in the reamed hole 11, fill the reamed hole 11 with a mixture of graphite powder and silicon powder at a mass ratio of 3:7, the mixture used The fixed carbon of graphite powder is not less than 99.99%, the mass purity of silicon powder is not less than 99.99%, the particle size of graphite powder and silicon powder is 100 mesh, and the d...

Embodiment 3

[0048] Embodiment three: a kind of preparation method of graphite silicon carbide thermocouple protective cover, comprises the following steps:

[0049] S1: Filling density in a cylindrical mold with an inner diameter of 100mm and a height of 180mm is 0.30g / cm 3 Graphite powder, the fixed carbon of graphite powder is not less than 95%, the particle size is 70 mesh, and the density of press molding is 1.70g / cm 3 The graphite tube body 1 has a wall thickness of 30 mm; the graphite tube body 1 is integrally formed with a central hole 13 and a reaming hole 11 .

[0050] S2: Take the graphite tube body 1 out of the mold, clean up the graphite powder in the reamed hole 11, fill the reamed hole 11 with a mixture of graphite powder and silicon powder at a mass ratio of 3:7, the mixture used The fixed carbon of graphite powder is not less than 99.99%, the mass purity of silicon powder is not less than 99.99%, the particle size of graphite powder and silicon powder is 200 mesh, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com