A high-performance special structure monodisperse carbon sphere negative electrode material and its preparation method and application

A technology of special structure and negative electrode material, applied in the field of high-performance special structure monodisperse carbon ball negative electrode material and its preparation, can solve the problems such as the large-scale preparation of Chaoitecarbon, which is convenient for industrial production, improves the sodium storage capacity, and the operation process. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

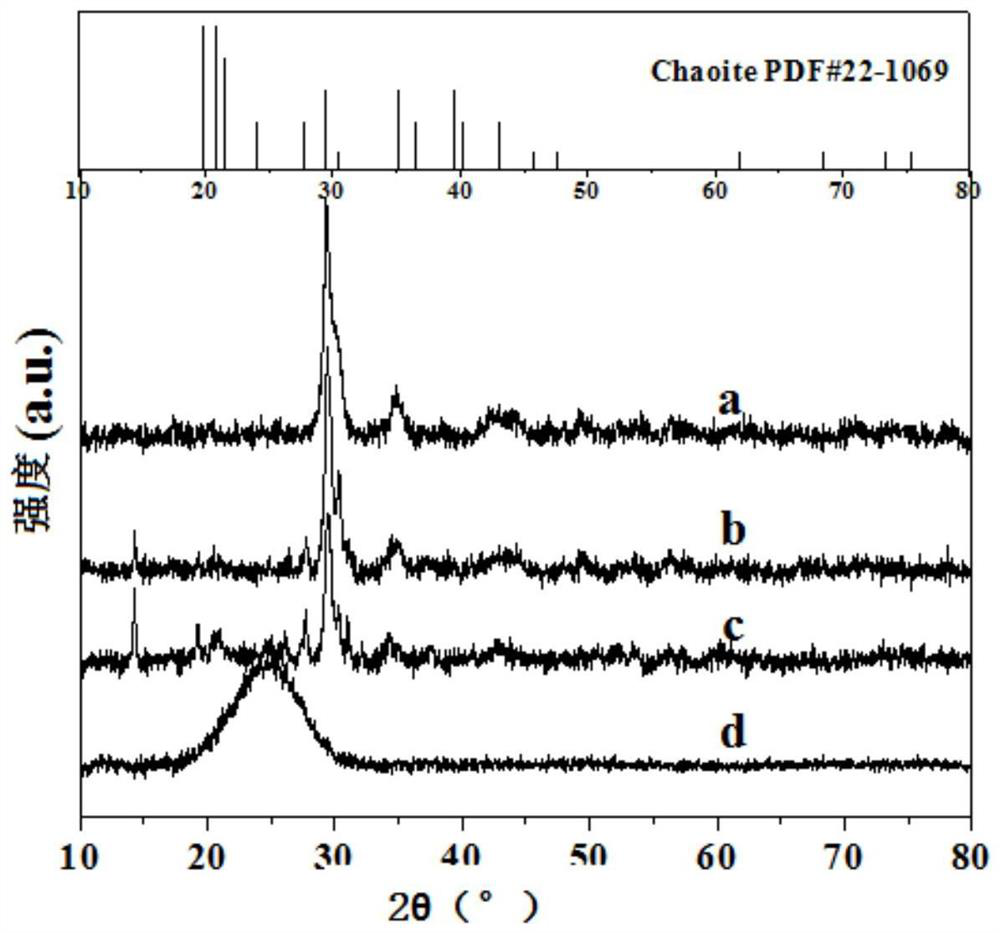

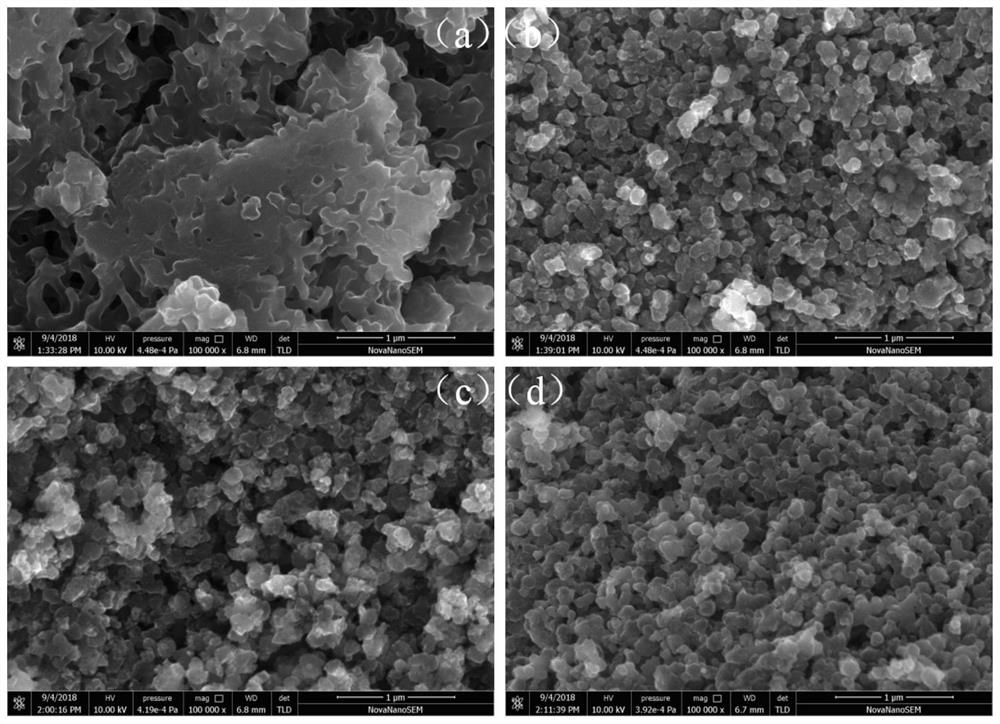

Embodiment 1

[0035] Disperse 0.1g of P123 in a certain amount of deionized water and ultrasonically stir until completely dissolved, then add 0.05g of Fe 2 (SO 4 ) 3 .7H 2O, stirred ultrasonically for 15 min; then started magnetic stirring in an ice bath for 20 min. Separately disperse 0.1mL of aniline in a certain amount of deionized water, and disperse evenly (no oil droplets) with ultrasonic stirring, add 0.1g of P123 and 0.08mL of phytic acid and disperse with ultrasonic stirring until completely dissolved; then start magnetic stirring in ice bath for 20min. The two solutions were mixed, and magnetically stirred for 20 minutes under ice bath conditions; another 6 mL of ammonium persulfate aqueous solution (containing 0.5 g of ammonium persulfate) was prepared, poured into the above mixed solution, and ice-bathed for 12 hours. After the reaction is finished, filter with suction, wash with deionized water for 3 to 5 times, and dry in vacuum at 70° C. for 3 to 5 hours to prepare precur...

Embodiment 2

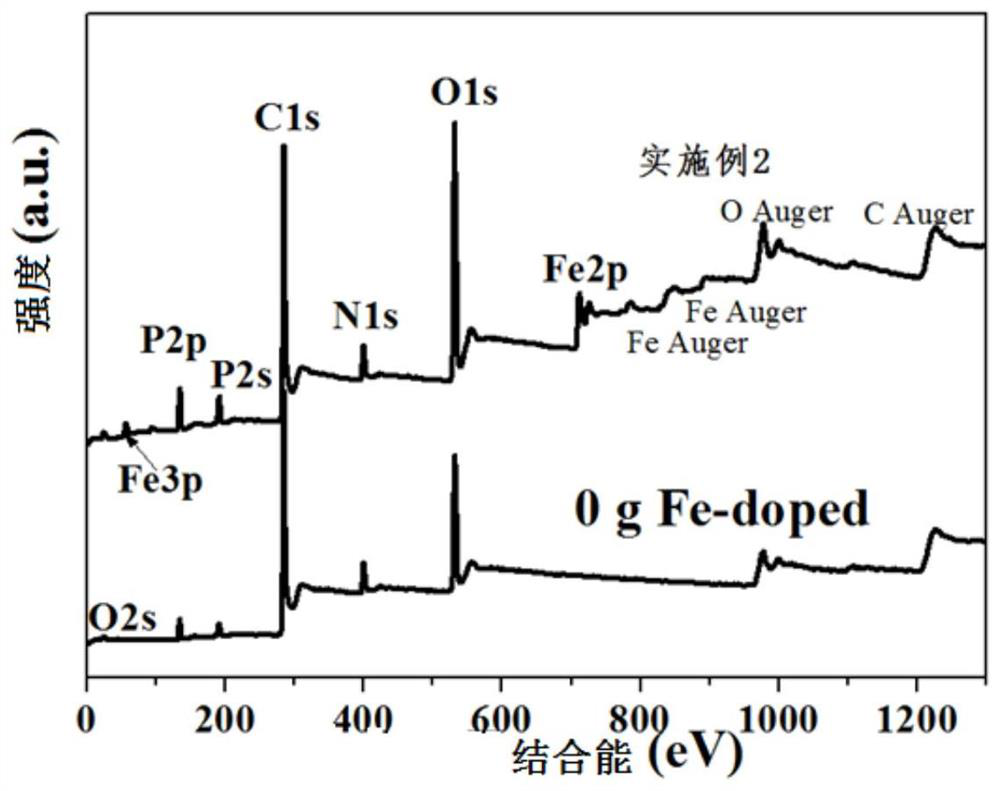

[0038] Disperse 0.2g of P123 in deionized water with ultrasonic stirring until completely dissolved, then add 0.3g of Fe 2 (SO 4 ) 3 .7H 2 O, stirred ultrasonically for 15 min; then started magnetic stirring in an ice bath for 20 min. Separately disperse 0.229mL of aniline in a certain amount of deionized water, stir ultrasonically to disperse evenly (without oil droplets), add 0.2g P123 and 0.46mL phytic acid and ultrasonically stir to disperse until completely dissolved; then start magnetic stirring in an ice bath for 20min. The two solutions were mixed, and magnetically stirred for 20 minutes under ice bath conditions; another 6 mL of ammonium persulfate aqueous solution (containing 0.5 g of ammonium persulfate) was prepared, poured into the above mixed solution, and ice-bathed for 12 hours. After the reaction is finished, filter with suction, wash with deionized water for 3 to 5 times, and dry in vacuum at 70° C. for 3 to 5 hours to prepare precursor monodisperse sphere...

Embodiment 3

[0041] Disperse 0.5g of P123 in deionized water with ultrasonic stirring until completely dissolved, then add 2g of Fe 2 (SO 4 ) 3 .7H 2 O, stirred ultrasonically for 15 min; then started magnetic stirring in an ice bath for 20 min. Separately disperse 0.916mL of aniline in a certain amount of deionized water, stir ultrasonically to disperse evenly (no oil drops), add 0.5g P123 and 1.35mL phytic acid and ultrasonically stir to disperse until completely dissolved; then start magnetic stirring in ice bath for 20min. The two solutions were mixed, and magnetically stirred for 20 minutes under ice bath conditions; another 6 mL of ammonium persulfate aqueous solution (containing 1.5 g of ammonium persulfate) was prepared, poured into the above mixed solution, and ice-bathed for 12 hours. After the reaction is finished, filter with suction, wash with deionized water for 3 to 5 times, and dry in vacuum at 70° C. for 3 to 5 hours to prepare precursor monodisperse spheres. The obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com