Electrolyte for rechargeable magnesium battery

An electrolyte and magnesium battery technology, applied in secondary batteries, secondary battery repair/maintenance, circuits, etc., can solve problems such as the need to improve the performance of electrolytes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Weigh magnesium trifluoromethanesulfonate and aluminum trichloride in a glove box filled with argon atmosphere, the molar ratio of magnesium trifluoromethanesulfonate to aluminum trichloride is 1:2, add tetrahydrofuran solution drop by drop , the concentration of magnesium trifluoromethanesulfonate is 0.125mol L -1 , placed in a magnetic stirrer and fully stirred to ensure that the solid was fully dissolved in tetrahydrofuran to obtain 0.125mol L -1 Magnesium trifluoromethanesulfonate + aluminum trichloride (1:2 molar ratio) / tetrahydrofuran electrolyte.

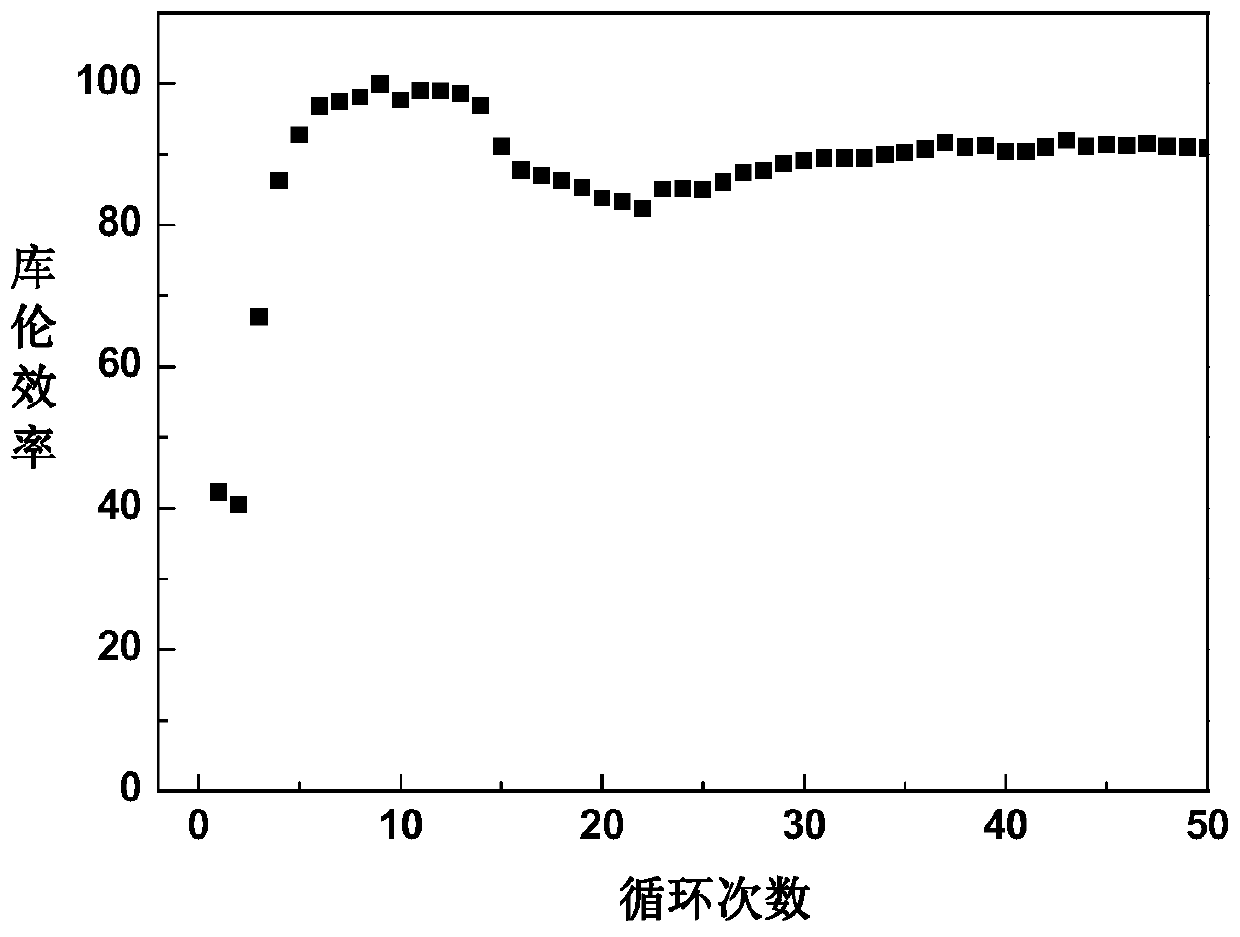

[0031] Using stainless steel as the positive electrode, add 0.3mL of 0.125mol L -1 Magnesium trifluoromethanesulfonate+aluminum trichloride (molar ratio is 1:2) / tetrahydrofuran electrolyte, metal magnesium as the negative electrode, polyethylene film as the diaphragm, assembled into a button cell, and carried out the magnesium deposition-dissolution performance test, The charge and discharge current is 0.088mA·cm ...

Embodiment 2

[0033] Weigh magnesium trifluoromethanesulfonate, aluminum trichloride and anthracene in a glove box filled with argon atmosphere, the molar ratio of magnesium trifluoromethanesulfonate to aluminum trichloride is 1:2, drop by drop Tetrahydrofuran solution, the concentration of magnesium trifluoromethanesulfonate is 0.125mol L -1 , the concentration of anthracene is 0.025mol L -1, placed in a magnetic stirrer and fully stirred to ensure that the solid was fully dissolved in tetrahydrofuran to obtain 0.125mol L -1 Magnesium trifluoromethanesulfonate + aluminum trichloride (molar ratio is 1:2) + 0.025mol L -1 Anthracene / THF electrolyte.

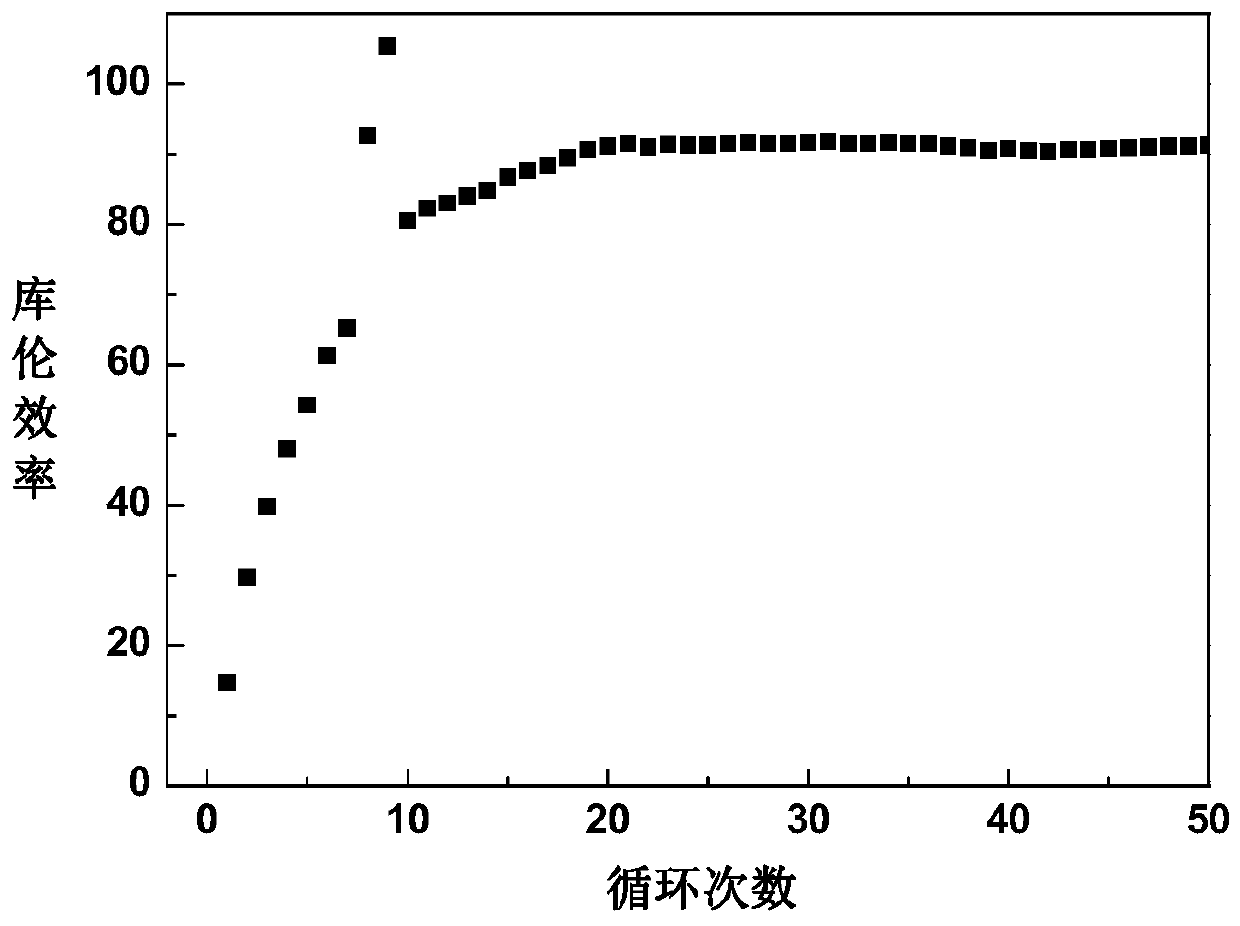

[0034] Using stainless steel as the positive electrode, add 0.3mL of 0.125mol L -1 Magnesium trifluoromethanesulfonate + aluminum trichloride (molar ratio is 1:2) + 0.025mol L -1 Anthracene / tetrahydrofuran electrolyte, metal magnesium as the negative electrode, polyethylene film as the diaphragm, assembled into a button battery, and carried ...

Embodiment 3

[0036] Weigh magnesium trifluoromethanesulfonate, aluminum trichloride and magnesium chloride in a glove box filled with argon atmosphere, the molar ratio of magnesium trifluoromethanesulfonate to aluminum trichloride is 1:2, drop by drop Tetrahydrofuran solution, the concentration of magnesium trifluoromethanesulfonate is 0.125mol L -1 , the concentration of magnesium chloride is 0.25mol L -1 , placed in a magnetic stirrer and fully stirred to ensure that the solid was fully dissolved in tetrahydrofuran to obtain 0.125mol L -1 Magnesium trifluoromethanesulfonate + aluminum trichloride (molar ratio is 1:2) + 0.25mol L -1 Magnesium chloride / tetrahydrofuran electrolyte.

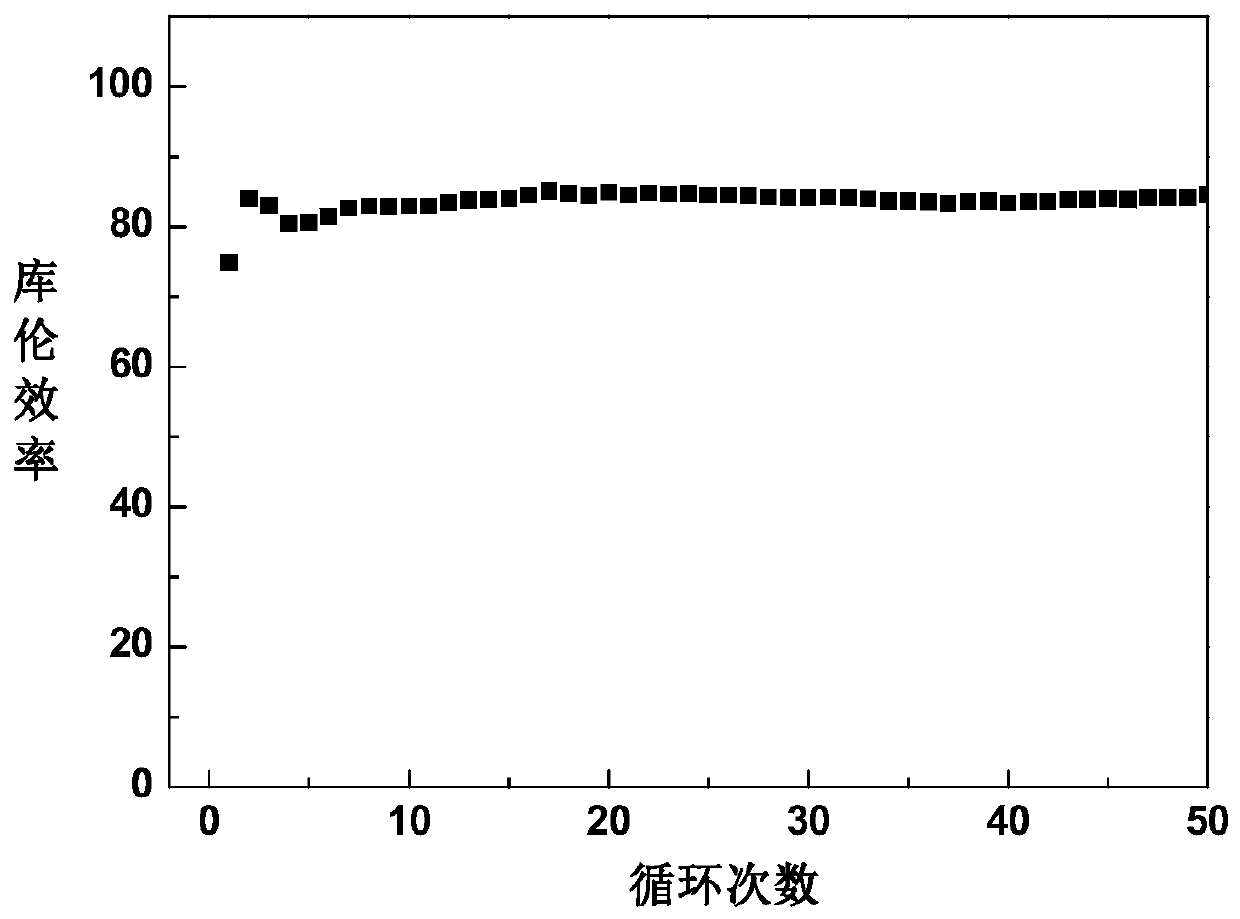

[0037] Using stainless steel as the positive electrode, add 0.125mol L -1 Magnesium trifluoromethanesulfonate + aluminum trichloride (molar ratio is 1:2) + 0.25mol L -1 Magnesium chloride / tetrahydrofuran electrolyte, metal magnesium as the negative electrode, polyethylene film as the diaphragm, assembled in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com