Electrolyte and lithium metal battery

A lithium metal battery and electrolyte technology, applied in non-aqueous electrolyte batteries, lithium batteries, secondary batteries, etc., can solve problems such as hindering the commercialization process of lithium metal batteries, reducing battery cycle performance, and many side reactions, and improving Safety performance and cycle stability, the effect of improving safety performance and cycle stability, and optimizing composition and structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

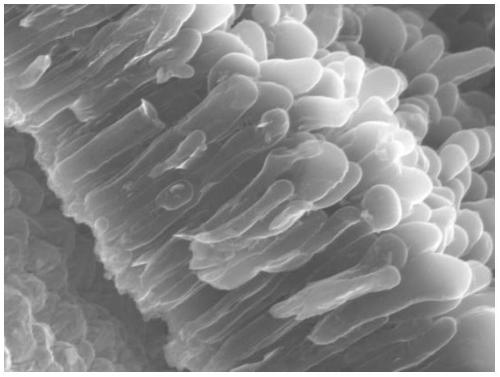

Image

Examples

Embodiment 1

[0057] Preparation of positive electrode

[0058] The positive electrode active material LiFePO 4 , conductive carbon black and binder PVDF are dispersed in the solvent NMP according to the mass ratio of 96:2:2 and mixed uniformly to obtain the positive electrode slurry; the positive electrode slurry is evenly coated on the positive electrode current collector aluminum foil, dried, cooled After pressing, slitting, and cutting into pieces, the positive electrode is obtained.

[0059] Preparation of negative electrode

[0060] A 140 μm thick lithium metal sheet was used as the negative electrode.

[0061] Separator

[0062] Use PE isolation film.

[0063] Electrolyte preparation

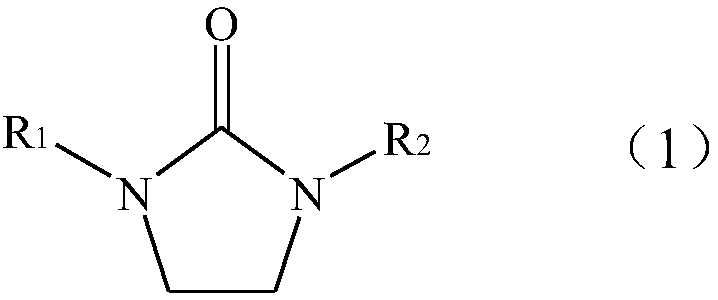

[0064] With the compound shown in formula 1-1 as solvent, LiNO 3 Dissolve in the solvent, mix uniformly, obtain electrolyte solution, wherein LiNO 3 The concentration is 1mol / L.

[0065] Preparation of lithium metal batteries

[0066] The above-mentioned positive electrode, separator a...

Embodiment 2~13 and comparative example 1~6

[0068] The difference from Example 1 is that the type of positive electrode active material and related parameters in the preparation steps of the electrolyte were adjusted, see Table 1 for details.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com