Resin composition, adhesive, sealing material, dam agent, semiconductor device and image sensor module

A technology of resin composition and sealing material, which is applied in the direction of semiconductor devices, semiconductor/solid-state device parts, adhesive additives, etc., can solve the problems of poor moisture resistance of resin compositions, and achieve the effect of high reliability and excellent pot life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

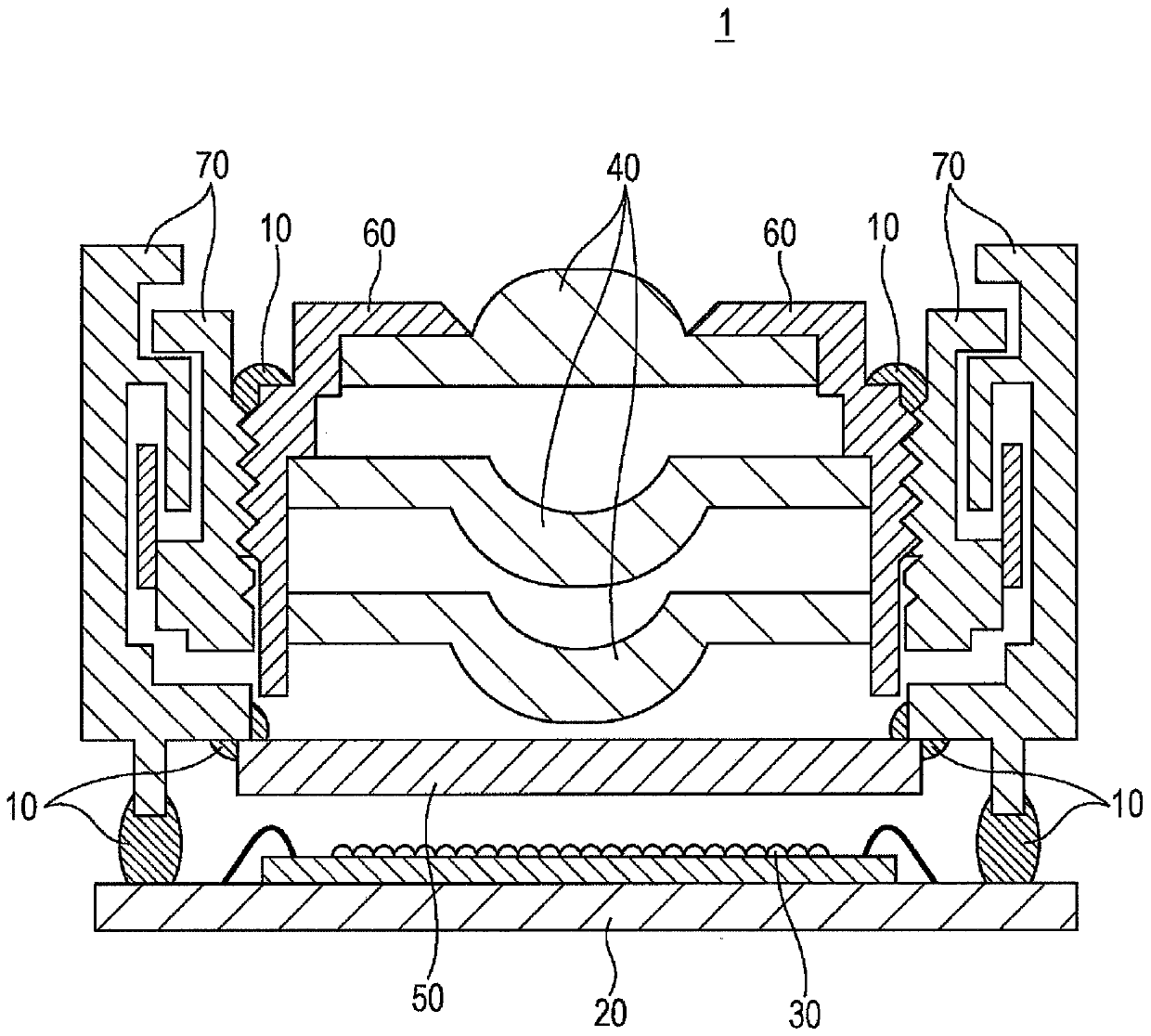

Image

Examples

Embodiment

[0085] Hereinafter, this embodiment will be described using examples. However, this embodiment is not limited by these Examples. In addition, in the following examples, parts and % represent parts by mass and % by mass unless otherwise specified.

[0086] According to the formulations shown in Tables 1 and 2, the resin composition was prepared using a three-roll mill. In Tables 1 to 2, the aforementioned (b2) is exemplified as the (B') component. In addition, as (B") and (B'') components, the aforementioned (b1) is exemplified. Moreover, when (C) contains an epoxy resin, the epoxy functional group equivalent contained in (C) is calculated|required, and a functional group equivalent ratio is computed.

[0087] 〔Viscosity〕

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com