High-speed corrugated paper multi-color flexographic printing slotting die-cutting glue box linkage line

A technology for flexographic printing and corrugated paper, which is applied in the field of high-speed corrugated paper multi-color flexographic printing slotting die-cutting and gluing box linkage line. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

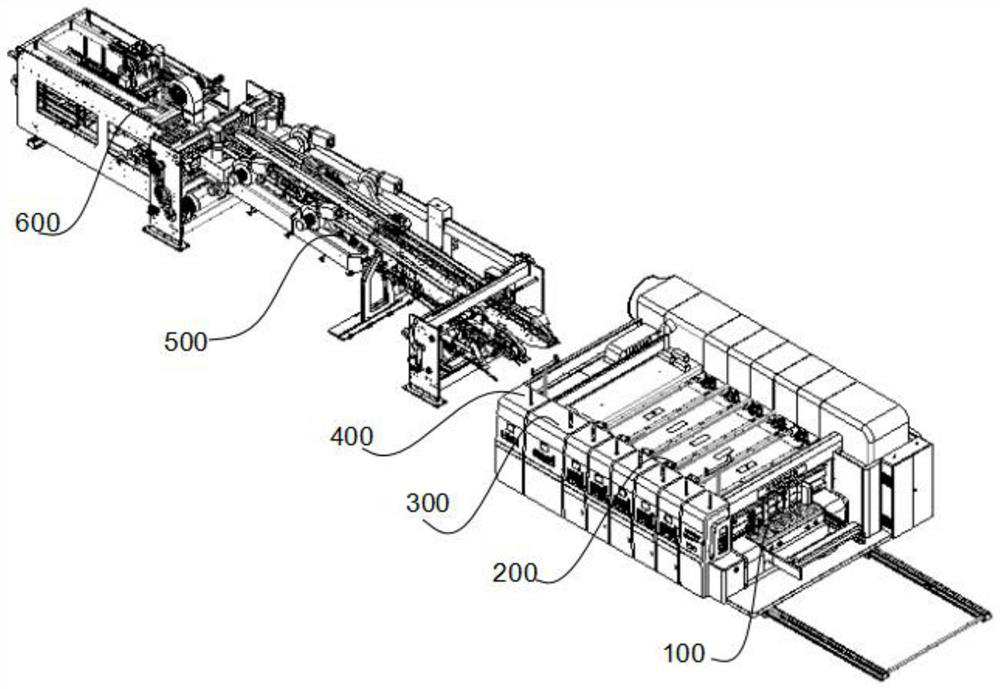

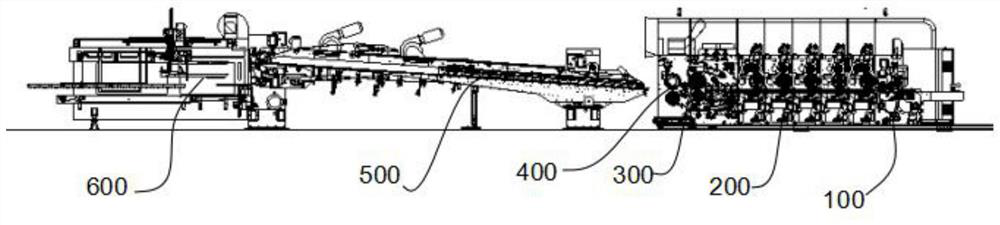

[0035] Embodiment: A high-speed corrugated paper multi-color flexographic printing slotting die-cutting glue box linkage line.

[0036] refer to Figure 1 to Figure 12 As shown, a high-speed corrugated paper multi-color flexo printing slotting die-cutting glue box linkage line, including:

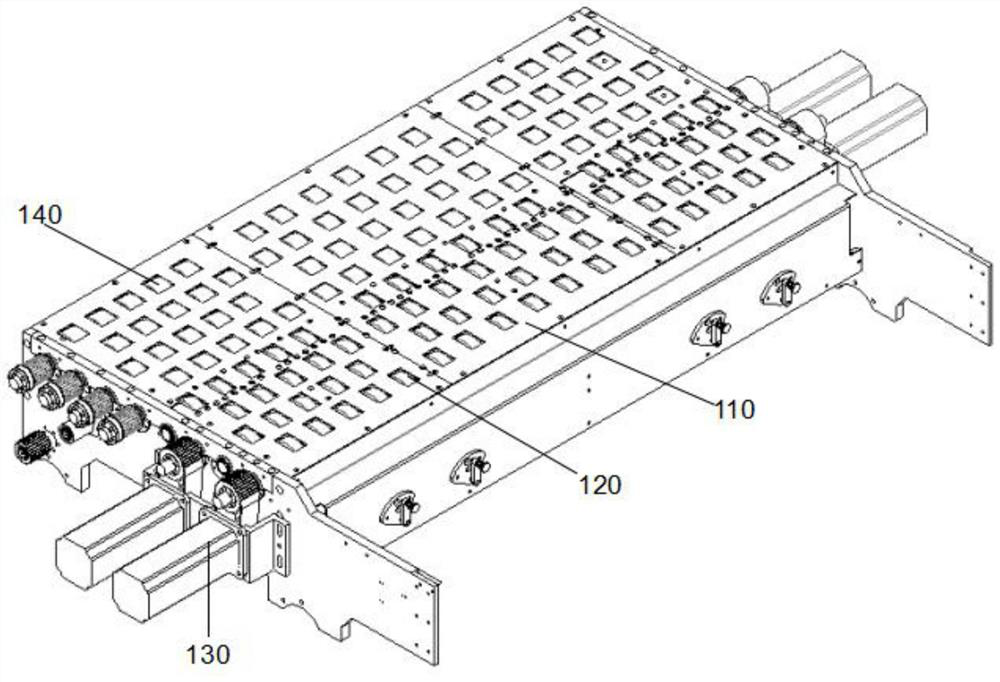

[0037] The pressure-free paper feeding mechanism 100, the pressure-free paper feeding mechanism 100 includes a paper feeding bellows 110, the surface of the paper feeding bellows 110 is provided with longitudinally staggered air holes, and the front end of the paper feeding bellows 110 is installed with four active transmissions. Rubber wheels 120, the end of each driving transmission rubber wheel 120 is equipped with a paper feeding drive servo motor 130, the top surface of the driving driving rubber wheel 120 is flush with the air hole, and the rear end of the paper feeding bellows 110 is Four passive transmission rubber wheels 140 are installed, and the top surface of the passive transm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com