Modified graphite felt electrode as well as modification method and application thereof

A technology of graphite felt modification and graphite felt, which is applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve the problems of inability to obtain stable and high-efficiency electrocatalytic anode materials, and achieve excellent electrochemical performance, Effect of improving electrochemical performance and enhancing oxidation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

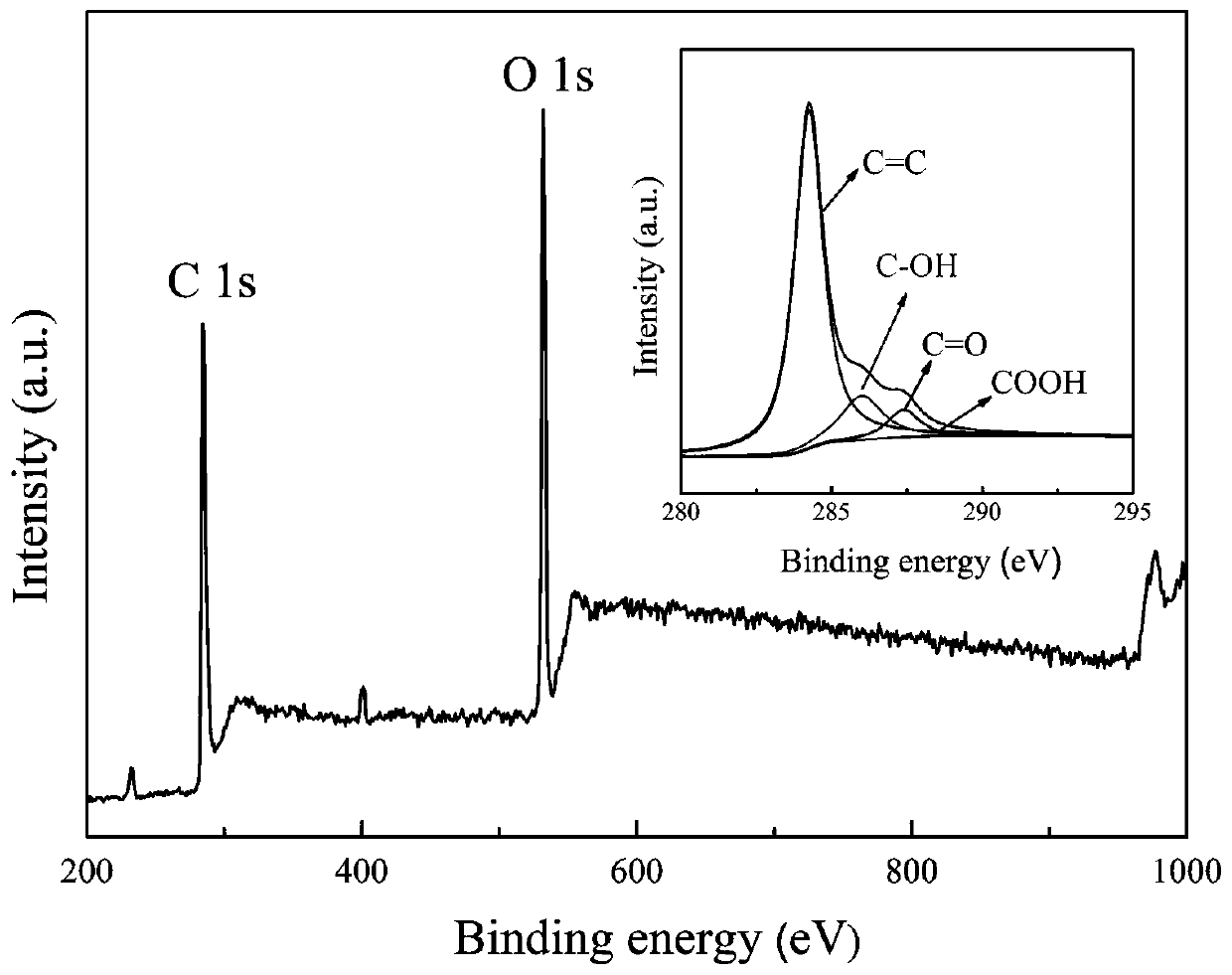

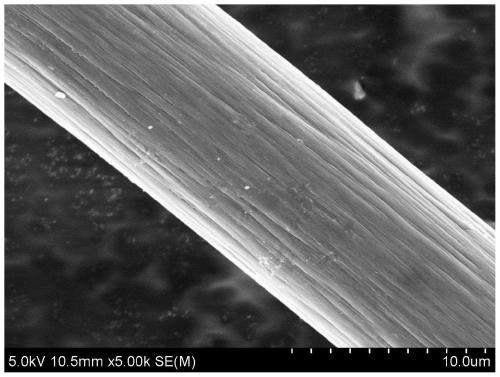

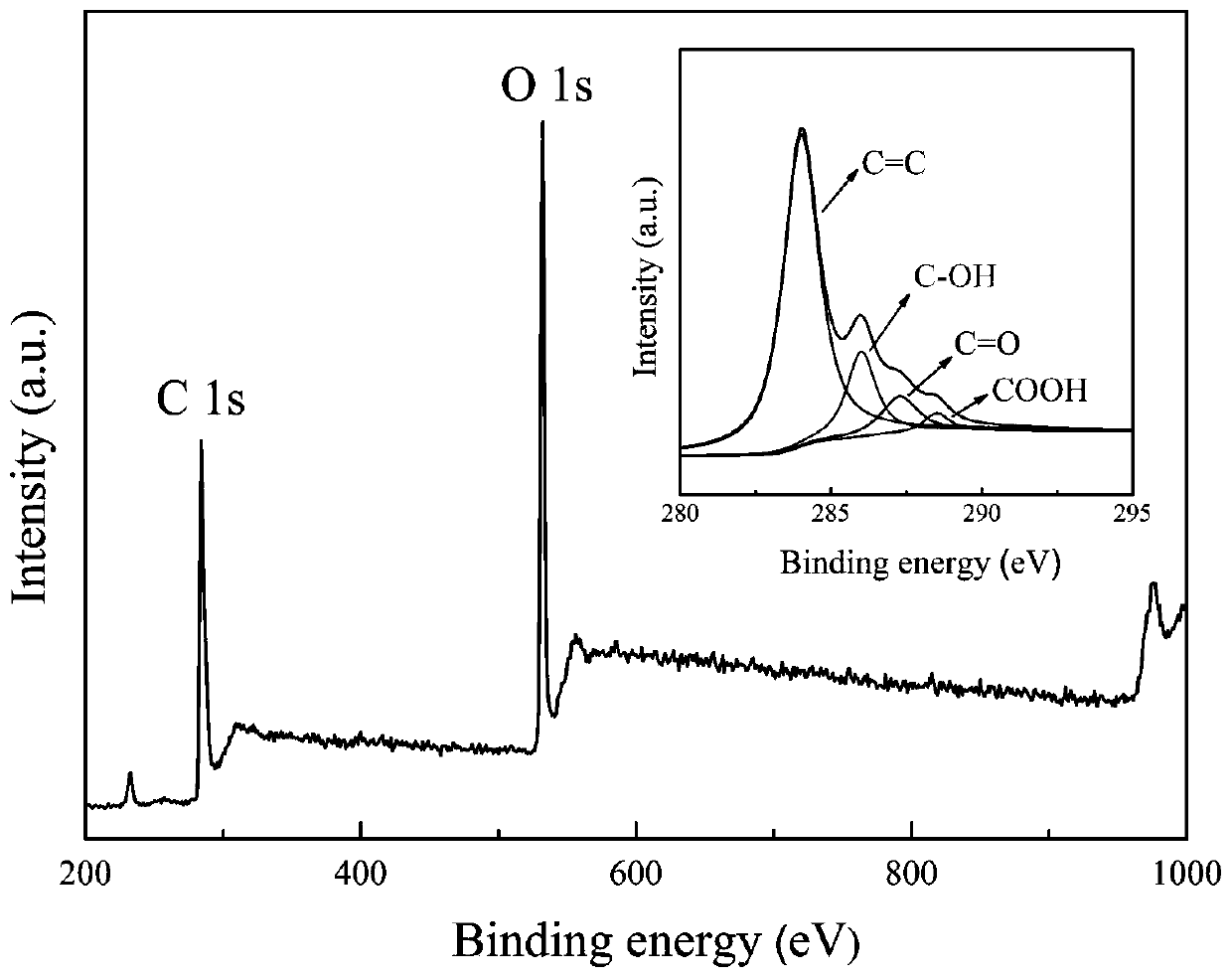

Method used

Image

Examples

Embodiment 1

[0036] (1) Put a 1cm×7cm graphite felt in isopropanol solution and ultrasonically clean it for 30 minutes to remove surface impurities, then rinse it with ultrapure water several times to completely remove the residual isopropanol in the graphite felt, and clean the rinsed graphite felt Put it in a blast drying oven at 60°C and dry it for later use;

[0037] (2) Take 98% concentrated sulfuric acid solution to prepare a sulfuric acid solution with a mass fraction of 10% for later use;

[0038] (3) The graphite felt pretreated in step (1) was used as the working electrode, the platinum sheet was used as the counter electrode, the mercury-mercurous sulfate electrode was used as the reference electrode, and the sulfuric acid solution prepared in step (2) was used as the electrolyte, and the counter electrode and The working electrode forms a path, and then the three electrodes are immersed in the electrolyte at a distance;

[0039] (4) Apply a linear scanning voltage on the worki...

Embodiment 2

[0045] (1) Put a 1cm×7cm graphite felt in isopropanol solution and ultrasonically clean it for 30 minutes to remove surface impurities, then rinse it with ultrapure water several times to completely remove the residual isopropanol in the graphite felt, and clean the rinsed graphite felt Put it in a blast drying oven at 60°C and dry it for later use;

[0046] (2) Take 98% concentrated sulfuric acid solution to prepare a 20% sulfuric acid solution for later use;

[0047] (3) The graphite felt pretreated in step (1) was used as the working electrode, the platinum sheet was used as the counter electrode, the mercury-mercurous sulfate electrode was used as the reference electrode, and the sulfuric acid solution prepared in step (2) was used as the electrolyte, and the counter electrode and The working electrode forms a path, and then the three electrodes are immersed in the electrolyte at a distance;

[0048] (4) Apply a linear scanning voltage on the working electrode, the initia...

Embodiment 3

[0054] (1) Put a 1cm×7cm graphite felt in isopropanol solution and ultrasonically clean it for 30 minutes to remove surface impurities, then rinse it with ultrapure water several times to completely remove the residual isopropanol in the graphite felt, and clean the rinsed graphite felt Put it in a blast drying oven at 60°C and dry it for later use;

[0055] (2) Take 98% concentrated sulfuric acid solution to prepare a sulfuric acid solution with a mass fraction of 2.5% for later use;

[0056] (3) The graphite felt pretreated in step (1) was used as the working electrode, the platinum sheet was used as the counter electrode, the mercury-mercurous sulfate electrode was used as the reference electrode, and the sulfuric acid solution prepared in step (2) was used as the electrolyte, and the counter electrode and The working electrode forms a path, and then the three electrodes are immersed in the electrolyte at a distance;

[0057] (4) Apply a linear scanning voltage on the workin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com