A kind of high solid content SBS emulsion and preparation method thereof

A high solid content, emulsion technology, applied in the field of polymer modification, can solve the problems of unstable SBS emulsion, single choice of emulsifier, restricting efficient production, etc., achieving significant energy consumption benefits, improving production efficiency, and reducing transportation costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

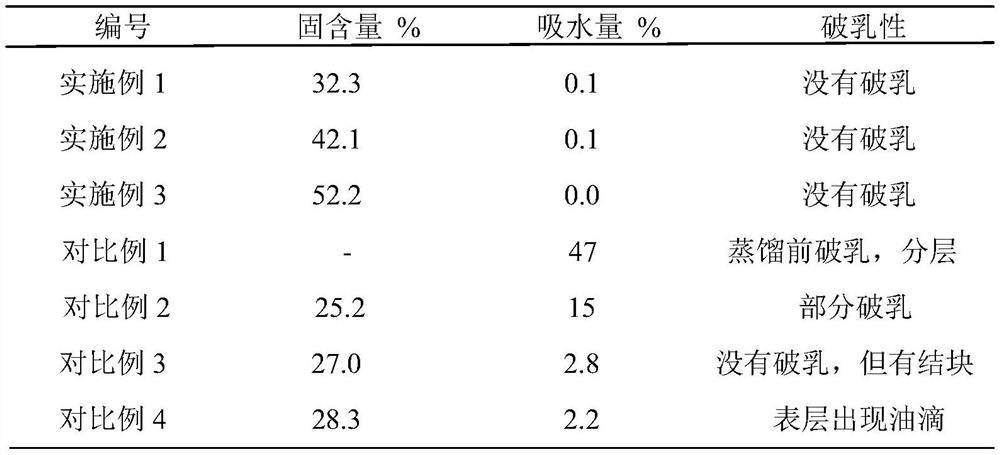

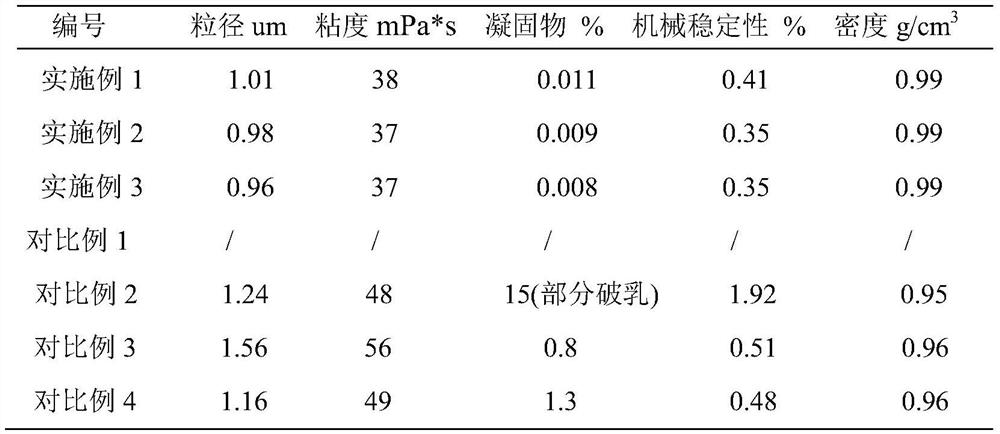

Examples

Embodiment 1

[0031] A kind of high solid content SBS emulsion, its preparation method comprises the steps:

[0032] 1) Preparation of SBS solution: Dissolve 30g of SBS in 140g of cyclohexane solution, stir evenly to form an SBS solution with a mass concentration of 12.5%;

[0033] 2) Preparation of composite emulsifier: Take 100g of water, add 6g of AC-181, 2g of OP-10, 2g of C 12 h 25 SO 4 Na, stirred evenly to form a compound emulsifier solution;

[0034] 3) Emulsification of high solid content SBS emulsion: shear the emulsifier aqueous solution at a low speed (about 2000rpm) for 3 minutes under a shearing machine, then slowly add the prepared SBS solution to it, add 0.1g of flocculant styrene, and increase the rotation speed To about 8000rpm, emulsify for 30min;

[0035] 4) Distillation and purification of high-solid content SBS emulsion: Purify the emulsified SBS emulsion in step 3) by vacuum distillation (pressure 84mmHg, temperature 45°C, time 8-12 hours), and the environmentally...

Embodiment 2

[0037] A kind of high solid content SBS emulsion, its preparation method comprises the steps:

[0038] 1) Preparation of SBS solution: Dissolve 40g of SBS in 150g of cyclohexane solution, stir evenly to form an SBS solution with a mass concentration of 16.7%;

[0039] 2) Preparation of composite emulsifier: Take 100g of water, add 6g of AC-181, 2g of OP-10, 2g of C 12 h 25 SO 4 Na, stirred evenly to form a compound emulsifier solution;

[0040] 3) Emulsification of high solid content SBS emulsion: shear the emulsifier aqueous solution at a low speed (about 2000rpm) for 3 minutes under a shearing machine, then slowly add the prepared SBS solution to it, add 0.1g of flocculant styrene, and increase the rotation speed To about 8000rpm, emulsify for 30min;

[0041] 4) Distillation and purification of high-solid content SBS emulsion: Purify the emulsified SBS emulsion in step 3) by vacuum distillation (pressure 84mmHg, temperature 45°C, time 8-12 hours), and the environmentally...

Embodiment 3

[0043] A kind of high solid content SBS emulsion, its preparation method comprises the steps:

[0044]1) Preparation of SBS solution: Dissolve 50g of SBS in 160g of cyclohexane solution, stir evenly and prepare a SBS solution with a mass concentration of 20%;

[0045] 2) Preparation of composite emulsifier: Take 100g of water, add 6g of AC-181, 2g of OP-10, 2g of C 12 h 25 SO 4 Na, stirred evenly to form a compound emulsifier solution;

[0046] 3) Emulsification of high solid content SBS emulsion: shear the emulsifier aqueous solution at a low speed (about 2000rpm) for 3 minutes under a shearing machine, then slowly add the prepared SBS solution to it, add 0.1g of flocculant styrene, and increase the rotation speed To about 8000rpm, emulsify for 30min;

[0047] 4) Distillation and purification of high-solid content SBS emulsion: Purify the emulsified SBS emulsion in step 3) by vacuum distillation (pressure 84mmHg, temperature 45°C, time 8-12 hours), and the environmentally...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com